Compound microbial agent for silage and application thereof in whole-plant corn silage

A technology of compound microbial bacterial agent and whole plant corn, applied in the direction of microorganism-based methods, microorganisms, applications, etc., can solve problems such as high water content, difficult to use, and nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Materials and methods:

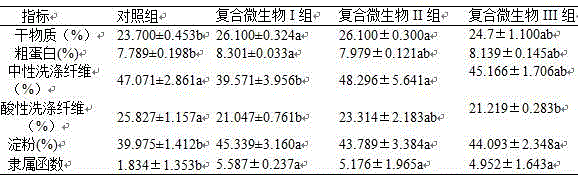

[0030] Separately prepare the dilutions of Pediococcus lactis, Lactobacillus plantarum and Bacillus coagulans, and mix them at the ratio of mass fraction 1:1:1, 1:1:10 and 1:10:10 respectively so that the total number of colonies is 1.0×10 9 CFU / ml of composite bacterial agents are respectively marked as composite bacterial agent group I, group II and group III.

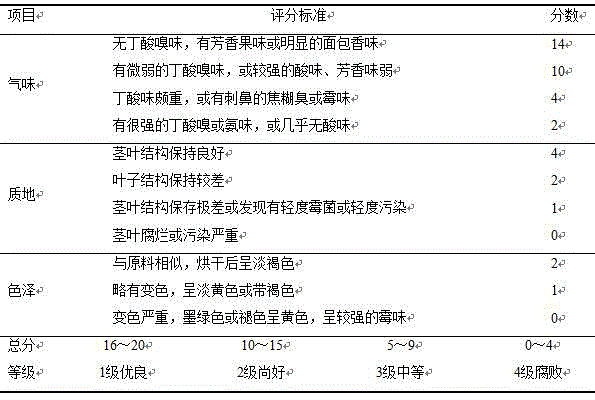

[0031] The corn at the end of milk ripening was harvested and chopped by a combine harvester, and a 1.5L fermentation tank was prepared, and 1.5kg of each tank was crushed to make silage from the whole plant corn. 100mL / t) + 15g bran (10kg / t) + 13.5g salt (10kg / t), the control group added 150μL distilled water to replace the compound bacterial agent, mixed the additive with the whole corn plant and put it in a fermenter, pressed After 15 days, the sensory (odor, texture and color) evaluation of the silage samples and the determination of various indicators of the silage fermentation q...

Embodiment 2

[0042] Materials and methods:

[0043] Separately prepare dilutions of Pediococcus lactis, Lactobacillus plantarum and Bacillus coagulans, and mix them at a mass fraction of 1:1:1 to obtain a total number of colonies of 5.0×10 9 CFU / ml compound bacterial agent.

[0044] Harvest and chop the corn at the end of milk ripening by a combine harvester, prepare a 1.5L fermenter tank, crush the whole plant corn at a rate of 1.5kg per tank to make silage, and the treatment groups are compound bacterial agent dose I (Pediococcus lactis: Lactobacillus plantarum: Bacillus coagulans=1:1:1) 75μL (50mL / t), compound bacterial dose II150μL (100mL / t) and compound bacterial dose III300μL (200mL / t)+15g bran (10kg / t)+13.5g Salt (9kg / t), the control group added 150μL distilled water to replace the compound bacterial agent, mixed the additive with the whole corn plant and put it in the fermenter, compacted and sealed, and the silage samples were sensory (odor, texture and color) after 15 days. ) e...

Embodiment 3

[0055] Materials and methods:

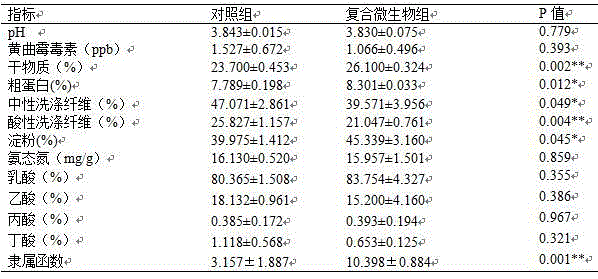

[0056] Preparation method of compound microbial agent: three strains of Pediococcus lactis (strain preservation number: CGMCC1.4), Lactobacillus plantarum (strain preservation number: ACCC11016), and Bacillus coagulans (strain preservation number: ACCC10229) were activated separately Cultured on MRS liquid medium, 10% inoculum, cultured at 37°C for 48 hours, mixed with MRS medium, mixed with a mass fraction of 1:6:9 to form a composite microbial agent, and the total number of colonies was 9.0×10 9 CFU / ml. All bacterial agents and MRS media are commercially available.

[0057] Method of use: In the process of silage material loading, the compound microbial agent is evenly sprayed on the crushed and timely harvested whole plant corn at an additive dosage of 150mL / t in layers, and bran (10kg / t) is evenly added at the same time and salt (9kg / t), compacted and sealed, and can be opened for use after 15 days, and no compound microbial agent was adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com