Method for carrying out dry quenching and gas making on coked red coke and coking wastewater treatment

A technology for coking wastewater and treatment methods, which is applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., and can solve problems such as increased energy consumption of furnaces or kilns, decreased mechanical strength, and unreasonable utilization of thermal energy. , to achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

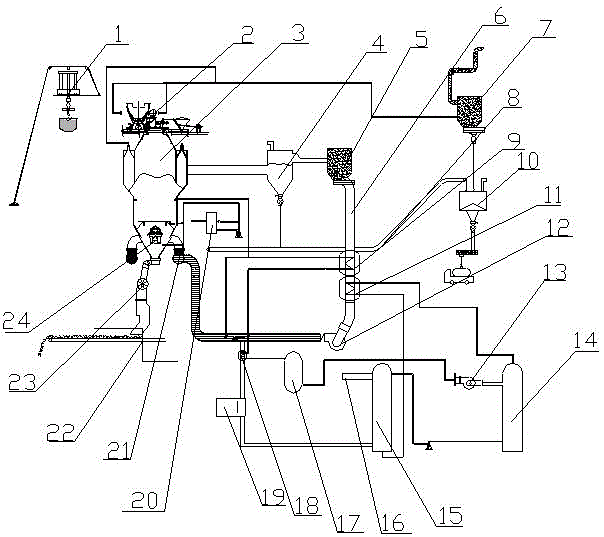

[0053] Combine below figure 1 The present invention is further described:

[0054] Taking a 1.3 million ton coking unit in a factory as an example, there are about 150 tons of coke per hour. The coke tank filled with red coke is pulled by an electric locomotive to the lifting derrick, and the automatic alignment device is used to align it with the lifting position.

[0055] The hoist lifts the coke pot filled with red coke and traverses to the top of the CDQ furnace, and the coke is loaded into the CDQ gas generator through the loading device with a charging bell.

[0056] The pre-storage section is used to accept intermittently loaded red coke, and has a buffer function to compensate for fluctuations in production. In the chute reaction zone, red coke mainly reacts with CO 2 Reacts with water vapour.

[0057] As the reaction progresses, the red coke, which is initially cooled to 700°C, enters the cooling reaction section downwards. Because the temperature of this part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com