Low-temperature early-strength toughening cement slurry and method for preparing same

A low-temperature early strength agent and cement slurry technology, applied in the field of cement slurry, can solve problems such as no successful experience, and achieve the effects of good stability, increased compressive strength and toughness, and low water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

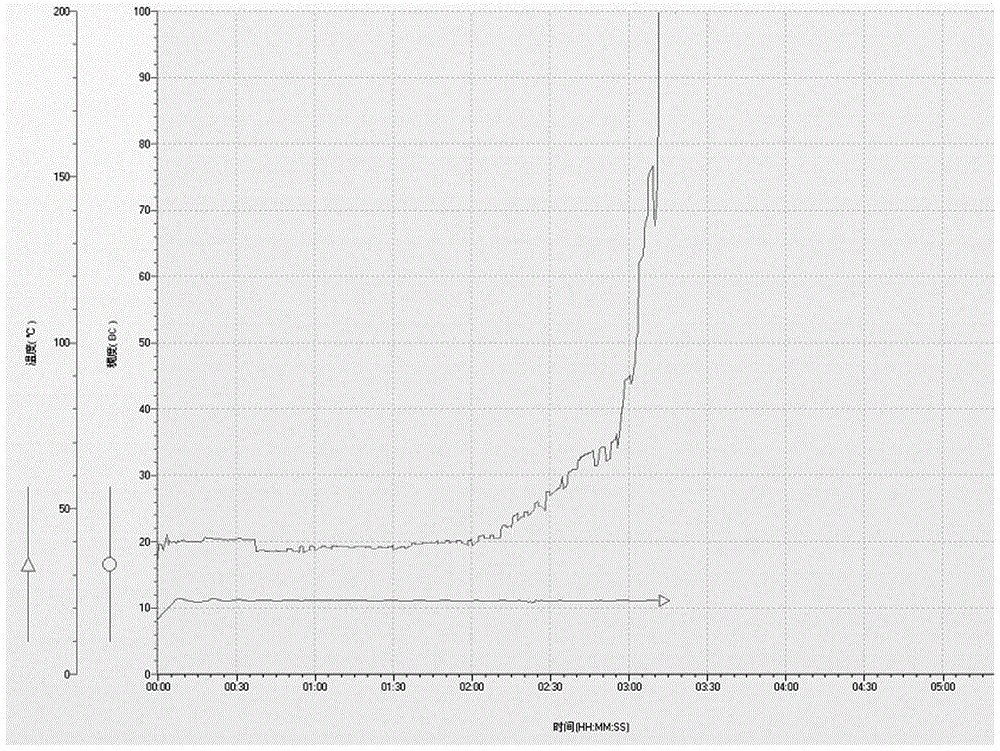

[0031] Weigh 100 parts by weight of high-resistance oil well cement, 1.8 parts by weight of low-temperature early-strength agent, 1.8 parts by weight of cementing agent, 0.8 parts by weight of drag reducer, and 2 parts by weight of low-temperature toughening agent, and dry mix it into a solid mixture; Take 44 parts by weight of water, 0.8 parts by weight of fluid loss reducer, and 0.2 parts by weight of defoamer and mix them into a solution in the stirring blade cup; pour the solid mixture into the stirring blade within 15 seconds at the speed of 4000±200r / min In the cup, stir at 12000 ± 500r / min at a high speed for 35s to prepare the low-temperature early-strength toughening cement slurry of the present invention. get as figure 1 The thickening curve shown.

Embodiment 2

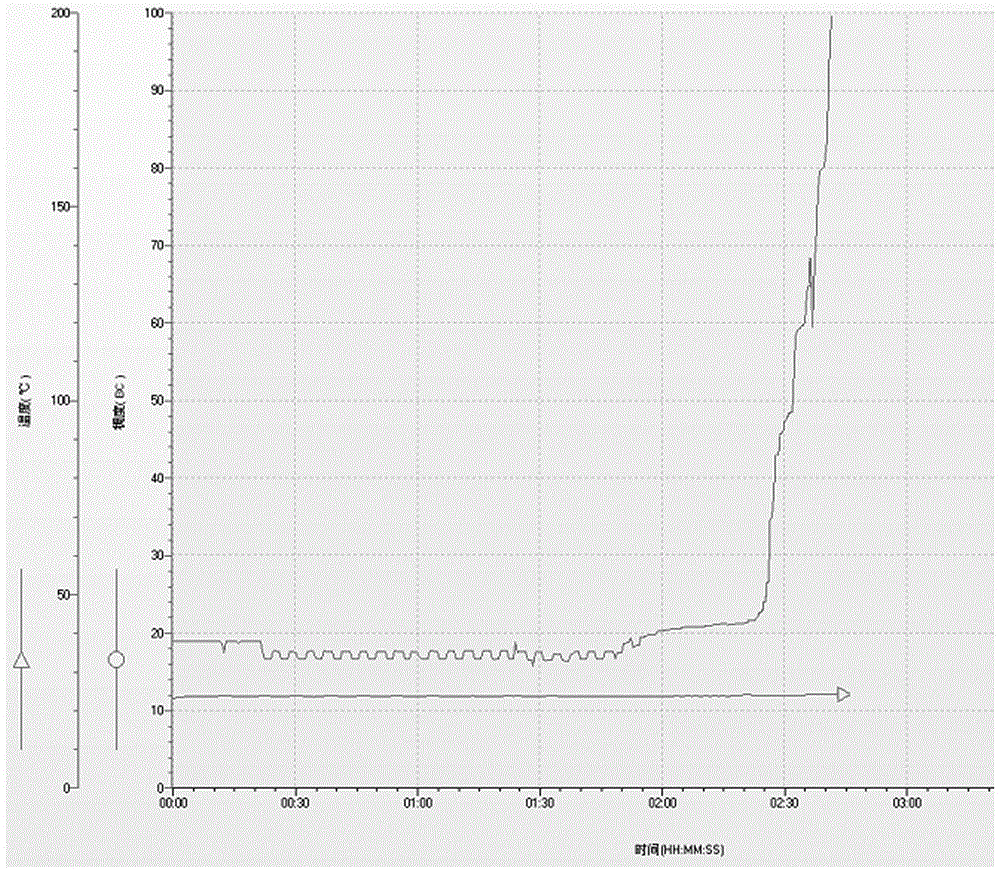

[0033] Weigh 100 parts by weight of high-resistance oil well cement, 1.5 parts by weight of low-temperature early strength agent, 1.8 parts by weight of cementing agent, 0.8 parts by weight of drag reducer, and 2 parts by weight of low-temperature toughening agent, and dry mix it into a solid mixture; Take 44 parts by weight of water, 0.8 parts by weight of fluid loss reducer, and 0.2 parts by weight of defoamer and mix them into a solution in the stirring blade cup; pour the solid mixture into the stirring blade within 15 seconds at the speed of 4000±200r / min In the cup, stir at a speed of 12000±500r / min for 35s to prepare low-temperature early-strength toughening cement slurry. figure 2 The thickening curve shown.

Embodiment 3

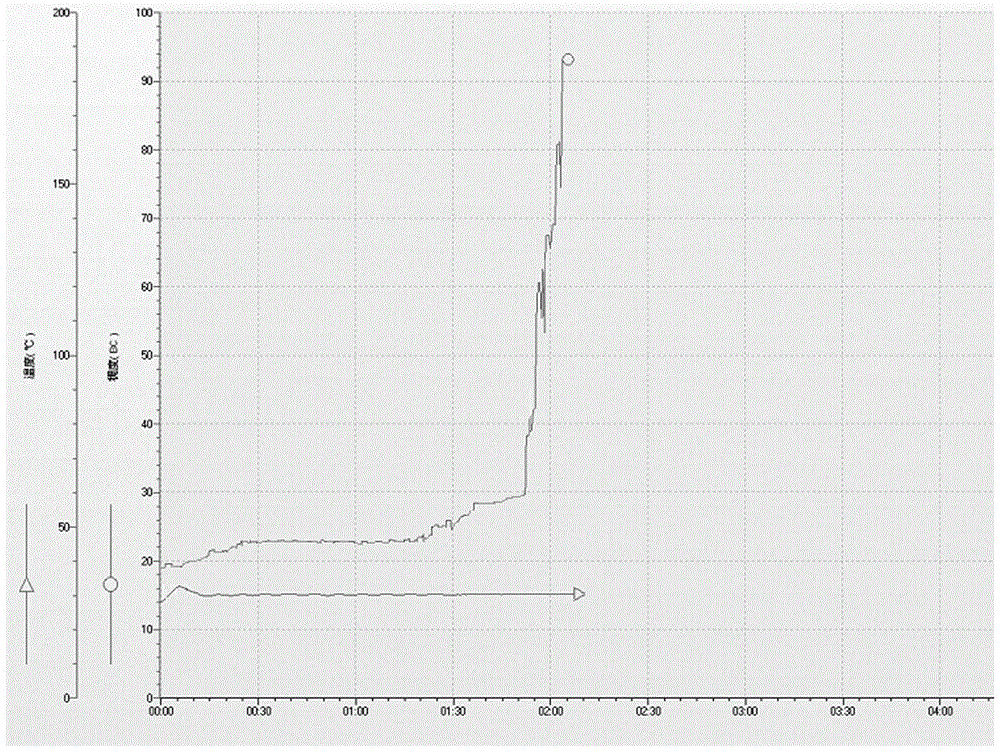

[0035] Weigh 100 parts by weight of high-resistance oil well cement, 1.0 parts by weight of low-temperature early-strength agent, 1.8 parts by weight of cementing agent, 0.8 parts by weight of drag reducer, and 2 parts by weight of low-temperature toughening agent, and dry mix it into a solid mixture; Take 44 parts by weight of water, 0.8 parts by weight of fluid loss reducer, and 0.2 parts by weight of defoamer and mix them into a solution in the stirring blade cup; pour the solid mixture into the stirring blade within 15 seconds at the speed of 4000±200r / min In the cup, stir at a speed of 12000±500r / min for 35s at high speed to prepare low-temperature early-strength toughening cement slurry. image 3 The thickening curve shown.

[0036] The low-temperature early-strength cement slurry system of the present invention has good stability, low water loss, and can significantly increase the compressive strength and toughness of cement stones at low temperatures, such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com