A kind of anti-scaling automatic water treatment equipment

A water treatment equipment and anti-scaling technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve obstacles, easily generate corrosion, and reduce the effectiveness of magnets Sexuality and other issues to achieve high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be described in detail in conjunction with specific embodiments.

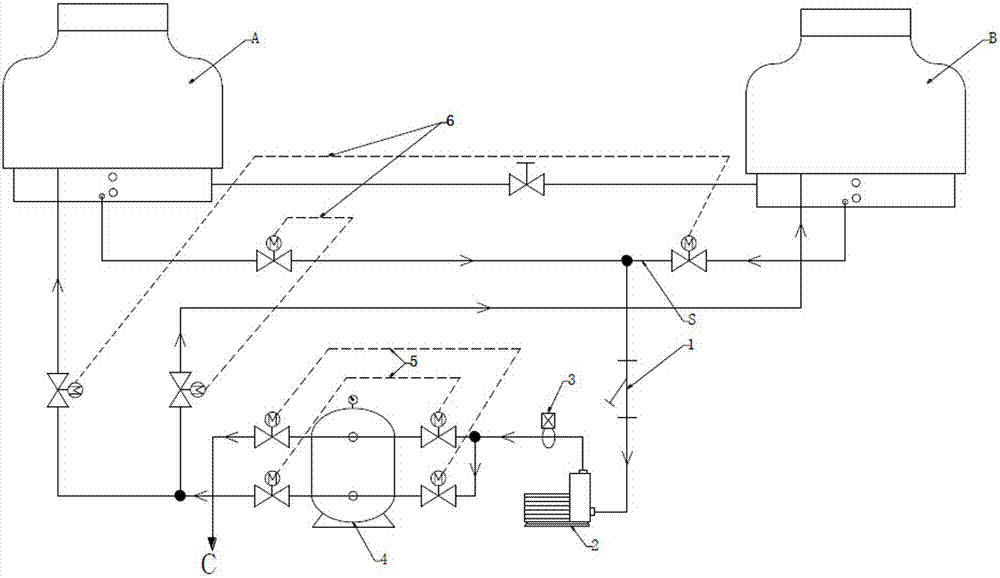

[0025] This embodiment takes the water treatment of two cooling towers as an example to describe the present invention in detail. For the overall structural diagram of the anti-scaling automatic water treatment equipment in this embodiment, please refer to the attached figure 1 , in the figure:

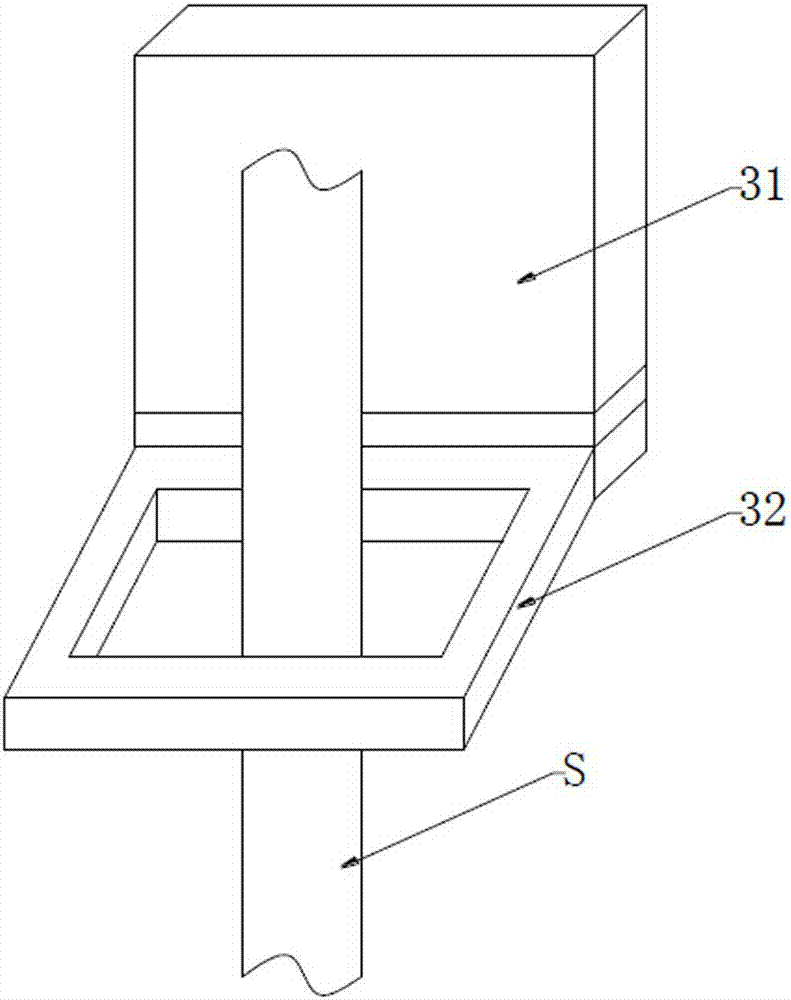

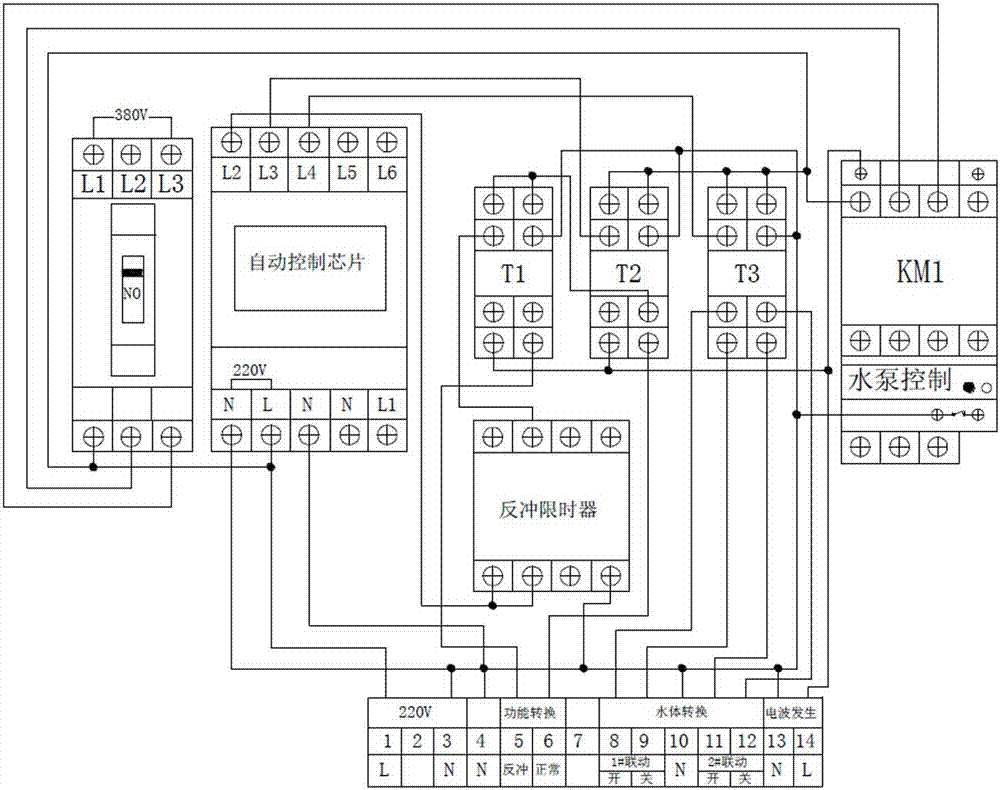

[0026] The cooling water towers A and B are connected to the filter 1 and the water pump 2 through the water pipe S, and then enter the filter sand tank 4 through the electric wave generator 3, and finally discharge impurities from the sewage outlet C. The connection of the pipeline and the valve is shown in the figure, and the valve Including the sand cylinder linkage control valve 5 and the water body linkage control valve 6, the switches of the valves, the water pump 2 and the electric wave generator 3 are all controlled by the control system. Among them, the filter 1 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com