Replaceable anti-scale device for embedded bubbler

A bubbler and anti-scaling technology, which is applied to water supply devices, fixed filter element filters, indoor sanitary piping devices, etc., can solve the problems of affecting the quality of tap water, easy to produce scale, and many tap water, etc., and achieves a simple and convenient structure. Replacement, sturdy effect of the filter unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

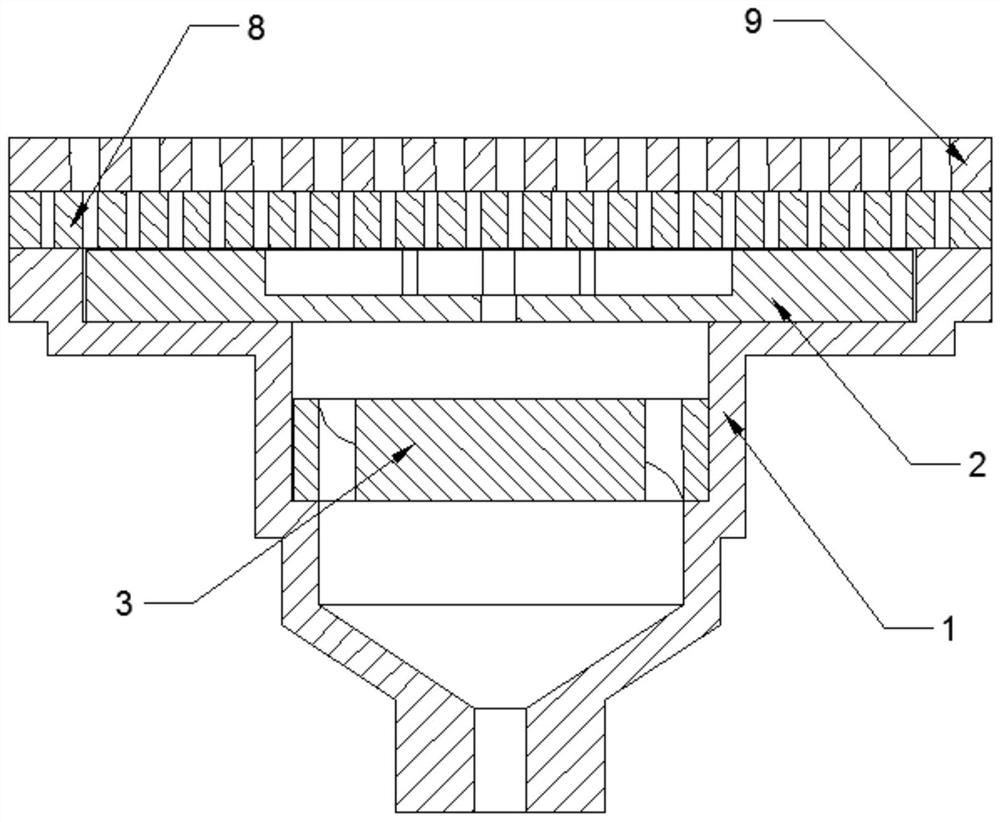

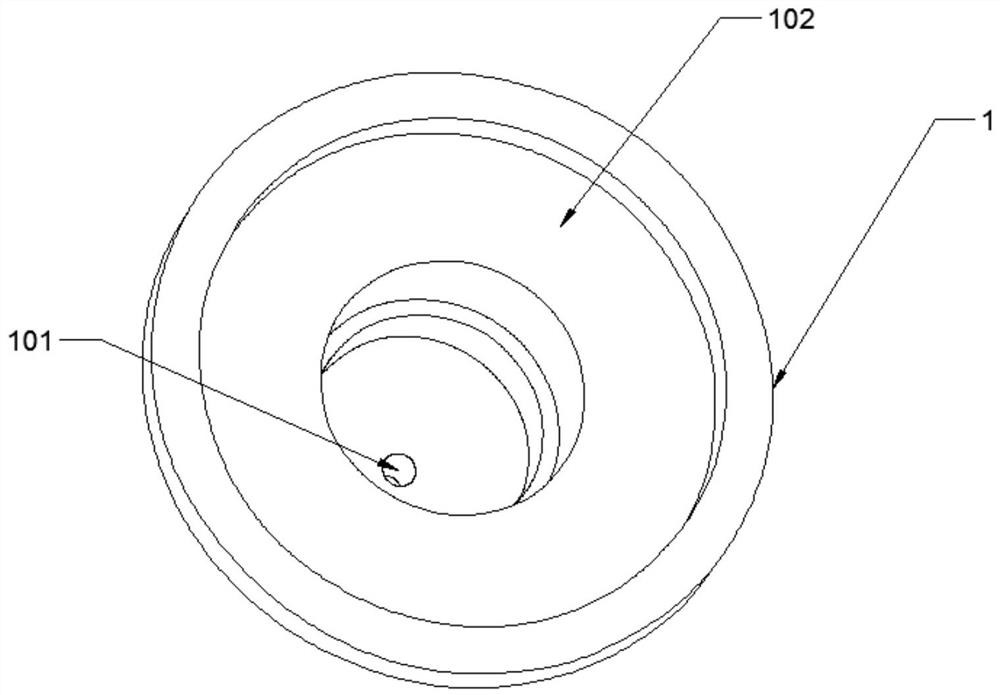

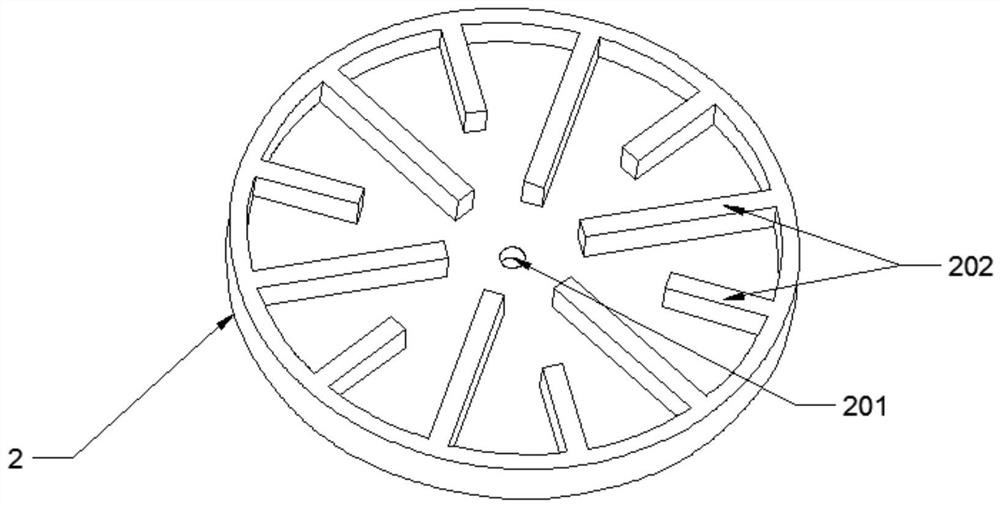

[0040] Such as Figure 1 to Figure 5 As shown, a replaceable anti-scaling device for an embedded bubbler includes a bubbler, wherein the bubbler includes a hollow shell 1 inside, and the shell 1 is a multi-step ladder with a large upper end and a smaller lower end Type cylindrical structure, the center of the bottom end of the housing 1 is provided with a water outlet 101, the top of the housing 1 is provided with an annular groove 102, and the annular groove 102 is provided with a pressure reducing piece 2, and the housing 1 The inner sleeve is provided with a water diversion sheet 3, and the water diversion sheet 3 is arranged between the pressure reducing sheet 2 and the water outlet 101, and a filter screen 8 and an anti-scaling silica gel filter screen are sequentially arranged above the housing 1 9. Both the filter screen 8 and the anti-scaling silica gel filter screen 9 are provided with a plurality of filter holes.

[0041] Further, the filter screen 8 is made of corr...

Embodiment 2

[0046] Such as Figure 3 to Figure 17 As shown, on the basis of Example 1, a secondary decompression sheet 7 is provided between the decompression sheet 2 and the water separation sheet 3, a step groove 104 is provided below the annular groove 102, and the step The bottom end of the groove 104 is evenly provided with a plurality of water outlet through holes 105, the casing 1 is provided with a switching head 5, the upper end of the switching head 5 is provided with a groove 501 for fixing the rubber ring 6, and the upper surface of the rubber ring 6 is A protrusion 601 corresponding to the water outlet hole 105 is provided.

[0047] Further, the lower end of the outer wall of the housing 1 is provided with a rounded table-shaped boss 106, and above the rounded table-shaped boss 106, a limit block 107 is arranged symmetrically. The buckle 502 matched with the rounded truncated boss 106 .

[0048] Further, the outer ring of the step where the housing 1 is in contact with the ...

Embodiment 3

[0056] Such as Figure 11 to Figure 13 As shown, on the basis of Embodiment 1, the housing 1 includes a spherical universal head A11 arranged at the upper end and a spherical universal head B12 arranged at the lower end, the spherical universal head A11 and the spherical universal head B12 Hinged, the spherical universal head B12 is sleeved on the bottom end of the spherical universal head A11, and the water diversion plate 3 is arranged in the spherical universal head B12.

[0057] The water flow first flows through the anti-scaling silica gel filter 9 to remove scale, and then flows through the filter 8 to filter impurities, and flows in from the top of the housing 1. The water flows in from the top of the spherical universal head A11 and passes through the decompression in the annular groove 102. Sheet 2 realizes the effect of wide water pressure, and then passes through the water diversion sheet 3 in the spherical universal head B12 to make the water flow generate a high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com