Formation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problems that the second wafer 20 is prone to cracking, affecting the performance and yield of MEMS devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] As mentioned in the background, in the existing manufacturing process of MEMS devices, wafer fragmentation often occurs, thereby affecting the performance and yield of MEMS devices. Analyze its reasons:

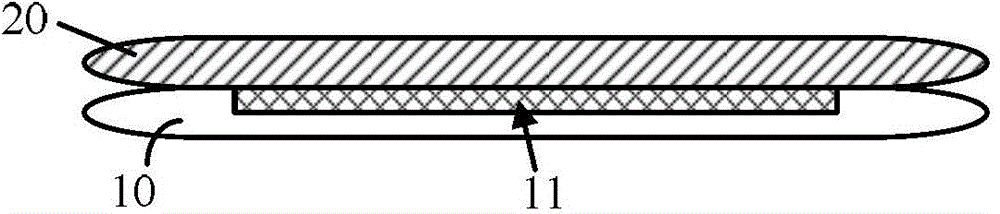

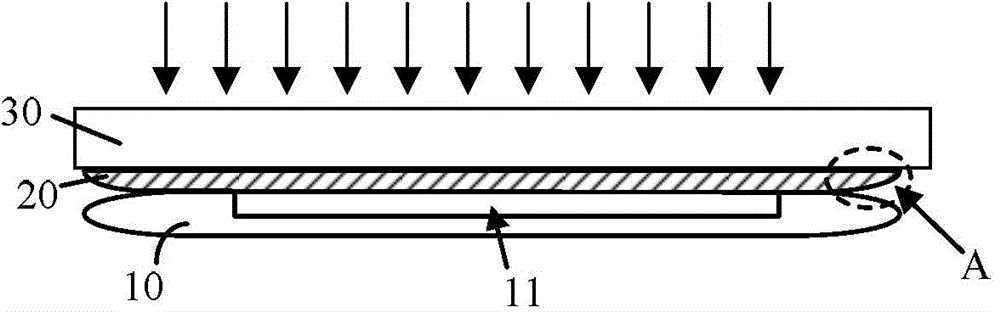

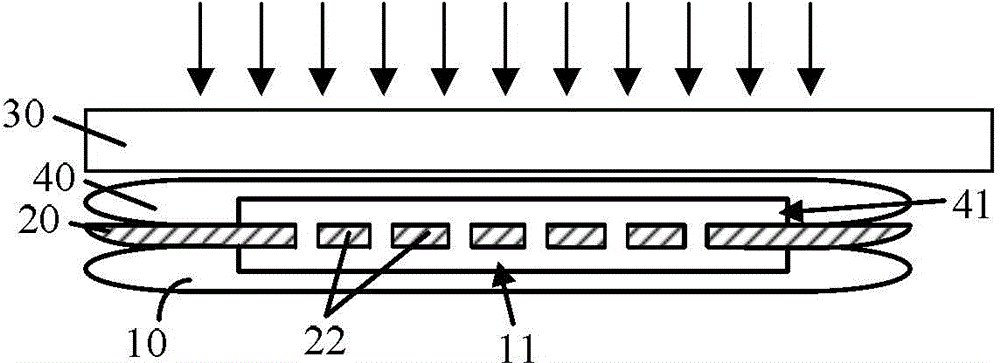

[0055] In the field of semiconductor manufacturing, existing wafers are mostly made of brittle materials such as silicon and germanium. In order to prevent wafers from being damaged due to bumping, the side walls of existing wafers are mostly arc-shaped curved surface structures. combined reference figure 2 with Figure 4 , in the preparation of MEMS devices, when the second wafer 20 is planarized, the edge of the second wafer 20 is in a suspended state not supported by the first wafer 10 (as shown in part A), so chemical During the grinding process of the second wafer 20 by mechanical grinding and other planarization techniques, the edge of the second wafer 20 is easily broken due to pressure, and cracks 21 with a large area appear on the edge of the second wafer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com