Small hoisting device

A small, reel technology, applied in the direction of lifting devices, etc., can solve the problems of construction safety hazards, large construction investment, low efficiency, etc., and achieve the effect of improving construction efficiency, improving construction safety factor, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

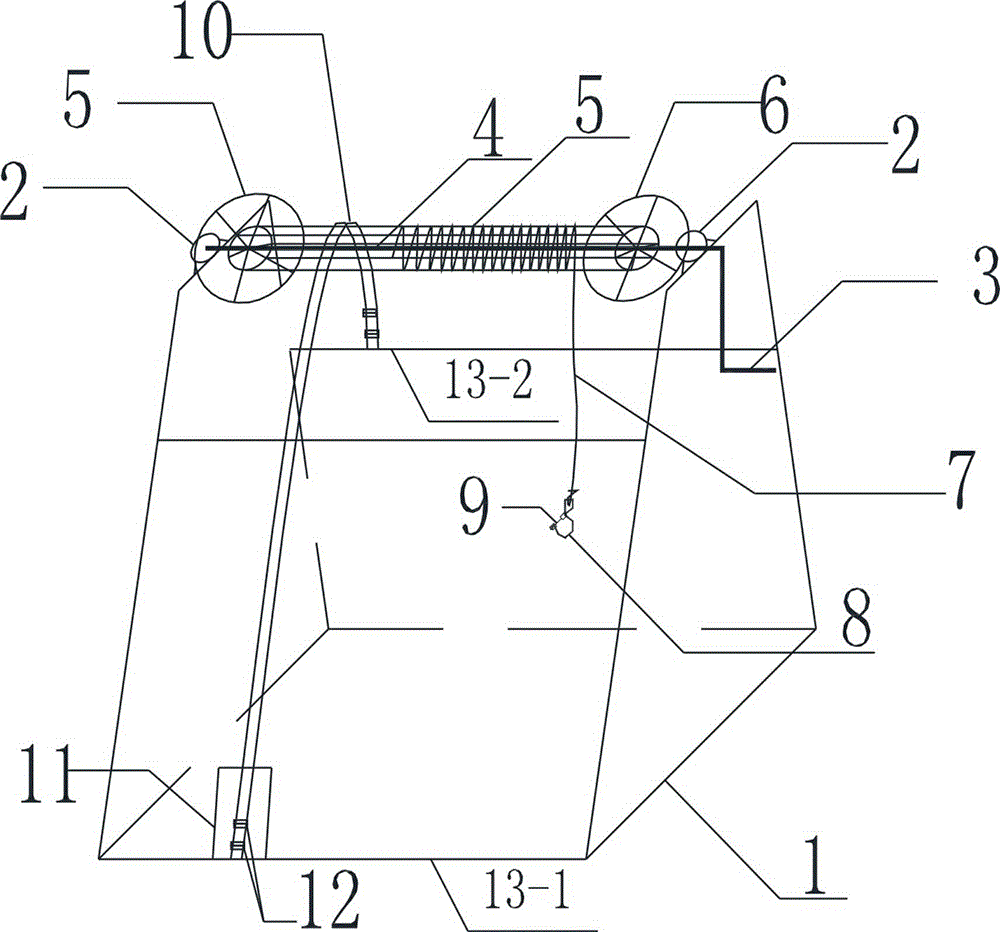

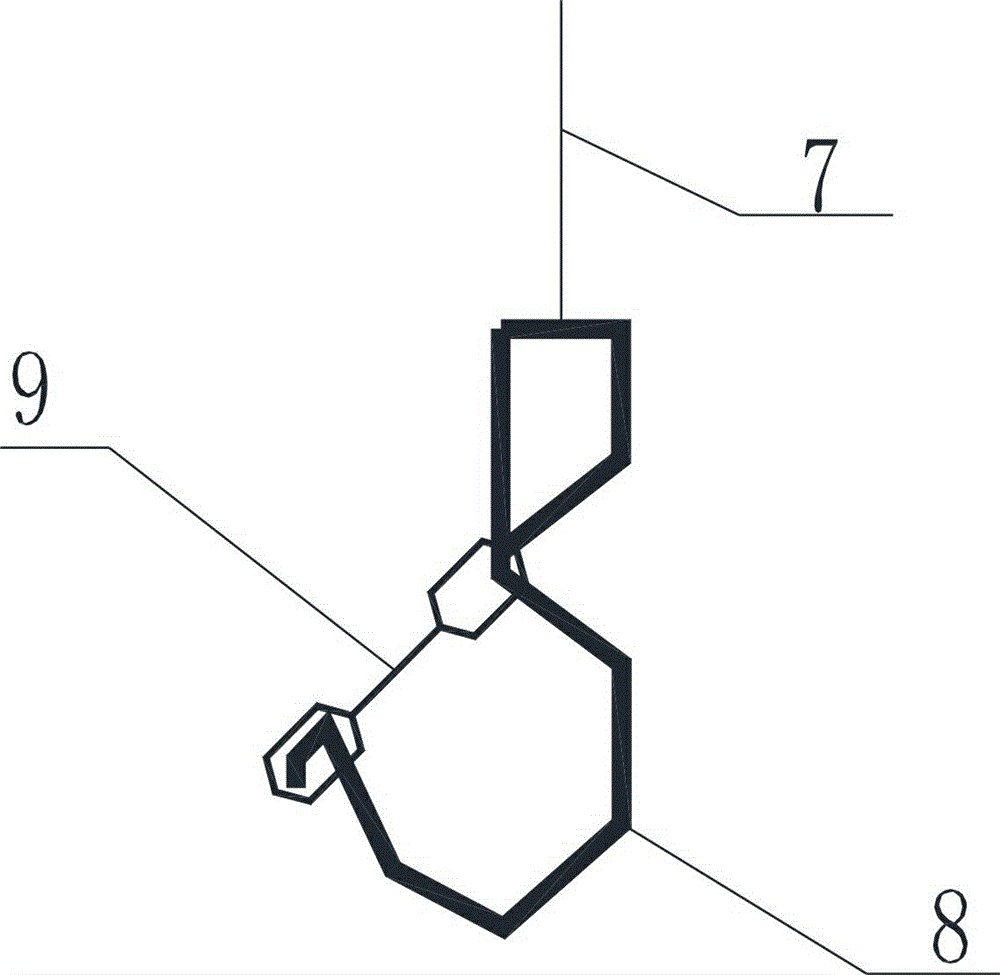

[0022] Such as figure 1 As shown, a small lifting device consists of an upper lifting structure, a braking system, and a lower support structure. The upper lifting structure is made up of: rocking handle 3, rotating shaft 4, reel 5, baffle plate 6, winding rope 7, suspension hook 8, the closed ring 9 of anti-decoupling. The brake system is made up of: brake band 10, brake pedal 11. The lower supporting structure is composed of: a bracket 1 and a ball bearing 2. Ball bearings are finished components, mainly composed of four basic elements: balls, inner rings, outer rings and retainers.

[0023] The ball bearing 2 is fixed on the bracket 1, the rotating shaft 4 passes through the ball bearing 2 and is welded and fixed with the rocker 3, the drum 5 is supported by steel bars and welded with the rotating shaft 4, and the drum 5 is connected with the winding rope 7, the hook 8 and the closed ring 9 Used in combination to form an upper lifting structure.

[0024] Bracket 1 is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com