Lifting residue-turning device

A technology of slag dumping and hoisting, which is applied in hoisting devices, hoisting devices, etc., can solve the problems of hidden dangers in construction safety of labor force physical fitness, complicated and inconvenient disassembly and assembly, and large construction investment. It achieves good application and promotion value, simple structure, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

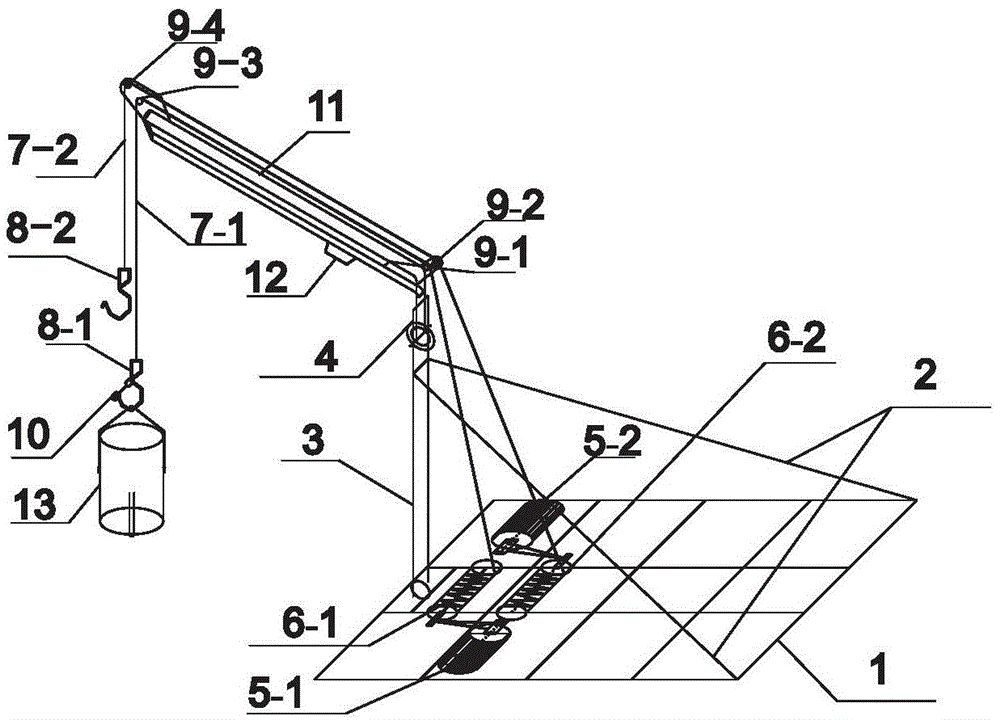

[0023] Such as figure 1 , figure 2 As shown, a lifting slag dumping device is composed of a support system, a lifting system, and a slag dumping system. The support system is composed of a chassis 1, a tie rod 2 and a cylinder 3. The support system is fixed on the chassis 1 with the cylinder 3, and the upper end of the cylinder 3 is connected and fixed with the tail end of the chassis 1 by using the tie rod 2.

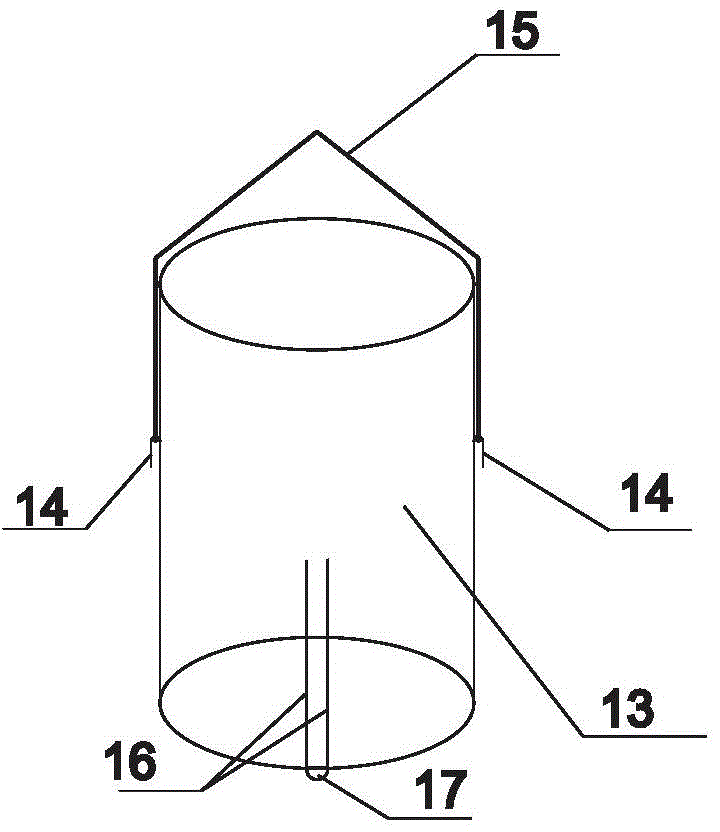

[0024] The hoisting system consists of drum 4, boom 11, handle 12, first fixed pulley 9-1, third fixed pulley 9-3, first motor 5-1, first hoist 6-1, first wire rope 7-1 , the first hook 8-1, the closed ring 10 to prevent decoupling and the slag bucket 13 are composed. The lifting system consists of installing and fixing the first motor 5-1 and the first hoist 6-1 on the chassis 1, connecting and fixing the drum 4 and the cylinder 3 through flanges, and fixing the first fixed pulley 9-1 on the boom 11. 1 and the third fixed pulley 9-3, one end of the first wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com