Aluminum trioxide sulfur recovery catalyst resistant to sulfation and preparation method thereof

A technology for the recovery of alumina trioxide and sulfur, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problems of low efficiency of de-oxygenation reaction , to achieve the effect of improving redox reaction process, improving catalytic efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] According to the present invention, the preparation method of above-mentioned catalyst comprises steps as follows:

[0014] (1) Ultrasonic dispersion of graphene in water, adding pseudo-boehmite and mixing evenly;

[0015] (2) with the material that step (1) obtains, add MnO 2 or CuO, knead evenly and dry;

[0016] (3) immersing the dried material obtained in step (2) in an iron salt solution for 1-15 hours, and drying again after the immersion is completed;

[0017] (4) The dried material in step (3) is kept at 450-550° C. for 3-6 hours at a constant temperature to obtain the finished catalyst.

[0018] According to the present invention, preferably, the mass ratio of graphene and pseudo-boehmite described in step (1) is (1-10):125, more preferably (3-8):125.

[0019] According to the present invention, preferably, MnO in step (2) 2 Or the mass ratio of CuO to pseudo-boehmite in step (1) is (1-8):125, more preferably (2-6):125.

[0020] According to the present in...

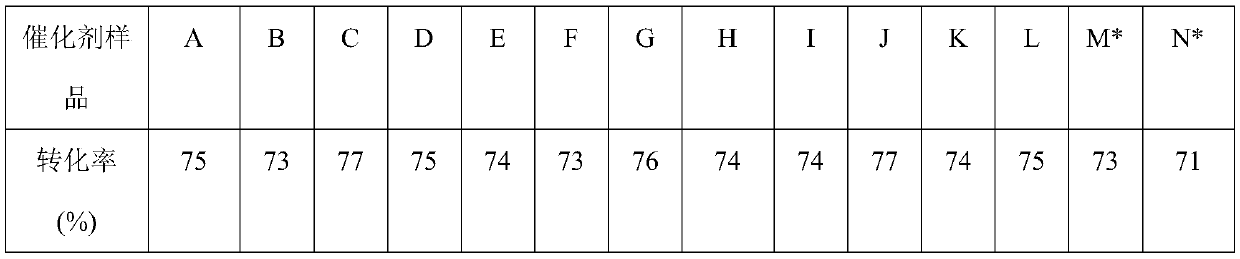

Embodiment 1

[0029] Take graphene 5g, join in 100mL water, ultrasonic dispersion is uniform, then weigh 125g pseudo-boehmite (water content 24.5%), join in above-mentioned graphene aqueous solution, after stirring, join in extruder, Add 3g MnO 2 Continue kneading for 1 hour, then extrude into a φ3mm strip, put it into an oven for 110°C×12h to dry; weigh 10g of ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (0), add 100mL of water to dissolve, impregnate the strip sample at room temperature for 12h, dry at 110°C for 12h, and roast at 500°C for 4h at a heating rate of 15°C / min to obtain catalyst sample A. The specific surface area of the sample is 276m 2 / g, the average crushing strength is 292N / cm.

Embodiment 2

[0031] Take graphene 5g, join in 100mL water, ultrasonic dispersion is uniform, then weigh 125g pseudo-boehmite (water content 24.5%), join in above-mentioned graphene aqueous solution, after stirring, join in extruder, Add 3g MnO 2 Continue kneading for 1 hour, then extrude into strips of φ3mm, put into an oven at 110°C×12h for drying; weigh 15g of ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (0), after adding 100mL of water to dissolve, impregnate the strip sample treated with graphene at room temperature for 12h, dry at 110°C for 12h, and roast at 500°C for 4h at a heating rate of 15°C / min to obtain catalyst sample B. The specific surface area of the sample is 267m 2 / g, the average crushing strength is 290N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average crushing strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com