Granulating device

A granulation device and support plate technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of affecting granulation efficiency, long granulation time, uneven particle size of materials, etc., and achieve good material separation effect and material forming effect Good, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

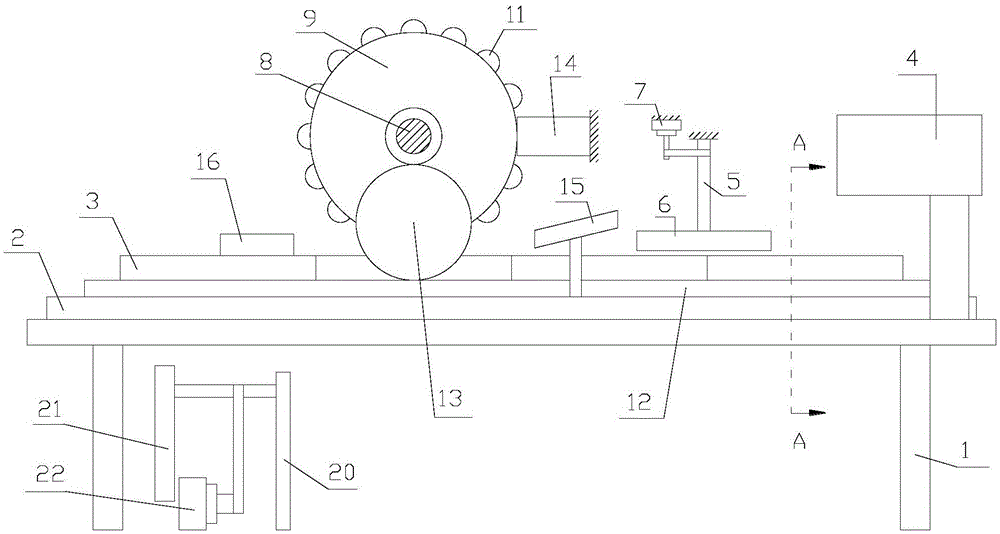

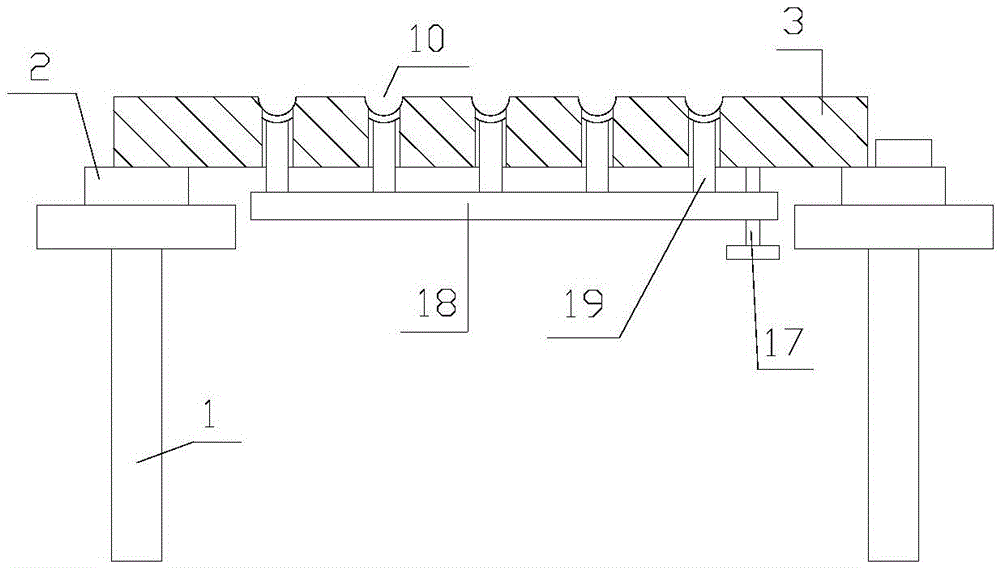

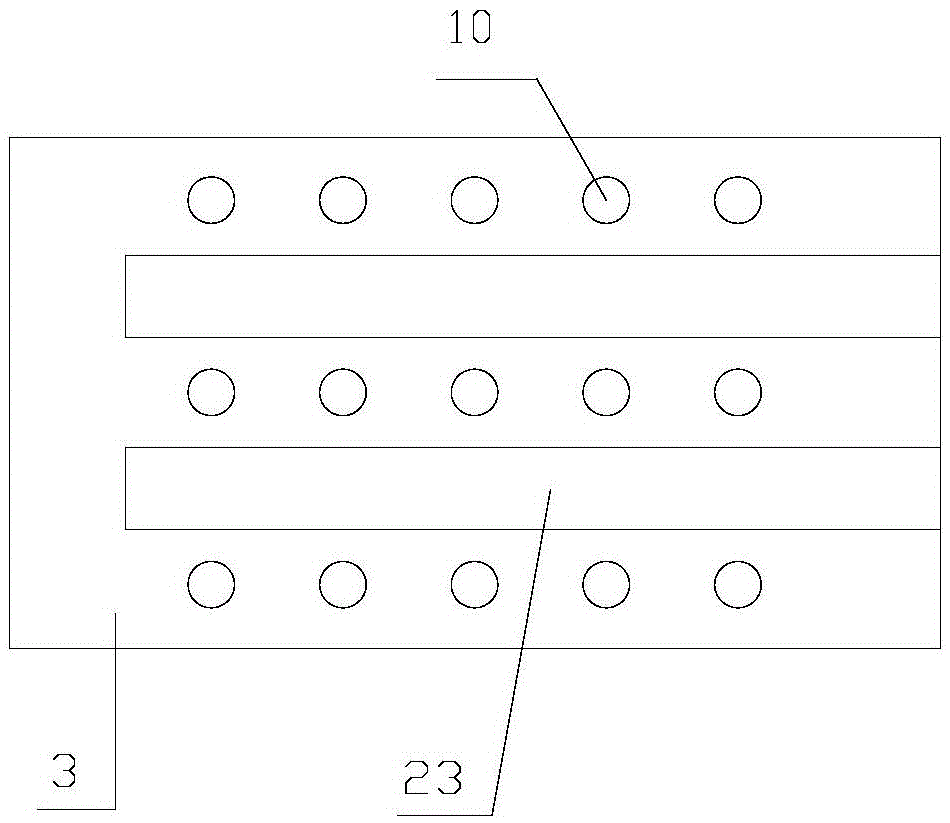

[0042] refer to figure 1 , 2 , 3:

[0043] A granulation device proposed by the present invention includes a support frame 1, a sliding plate 2, a plurality of support plates 3, a feeding box 4, a rotating shaft 5, a rotating plate 6, a first power unit 7, a supporting shaft 8, a pressure roller 9, Drive mechanism, cleaning plate 14, first baffle plate 15, second baffle plate 16, multiple unloading plates 18, bracket 20, eccentric wheel 21, second power unit 22.

[0044] The support frame 1 is provided with guide rails, and the guide rails are arranged horizontally.

[0045] Sliding plate 2 is movably installed on the guide rail.

[0046] A plurality of support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com