Built-in ultrasonic stirring crystallizer

A stirring crystallization and ultrasonic technology, applied in the field of built-in ultrasonic stirring crystallizer, can solve the problems of easy scaling and blockage of the heat exchange interface, easy crystallization of the heat exchange interface, and high energy consumption, to prevent crystallization, prevent equipment fouling, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

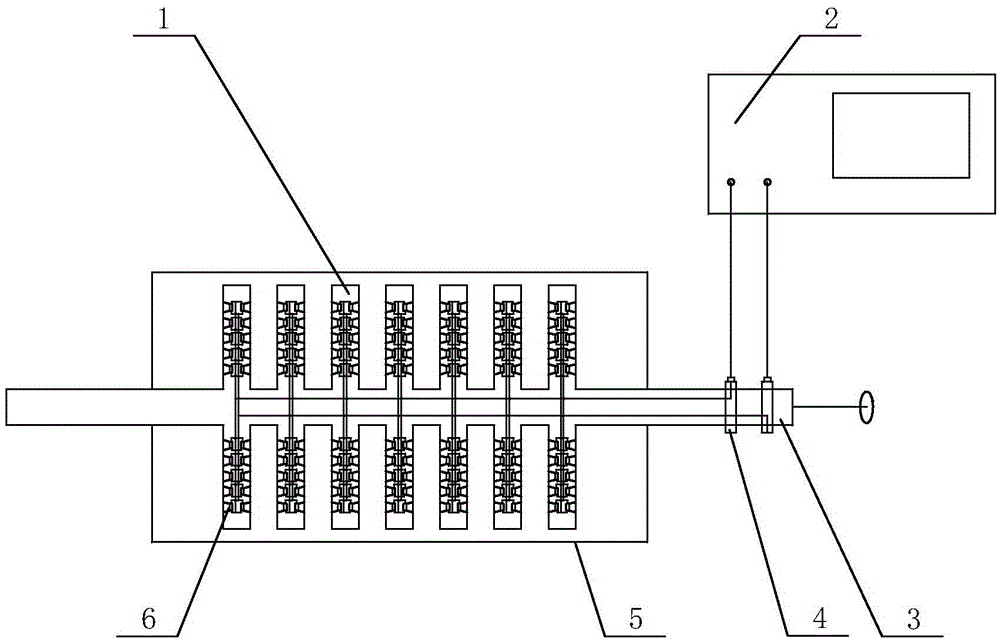

[0021] Such as figure 1 As shown, the built-in ultrasonic stirring crystallizer of the present invention includes a cylinder body 5, the central axis of the cylinder body 5 is provided with a hollow shaft 3, the two ends of the hollow shaft 3 pass through the cylinder body 5, two of the hollow shaft 3 A plurality of vibrator groups 1 are provided on the side, a plurality of ultrasonic vibrators 6 are provided inside the vibrator group 1, and a brush group 4 is provided at one end of the hollow shaft 3, and one end of the brush group 4 is connected to the ultrasonic vibrator 6 through a wire, The other end is connected to the ultrasonic generator 2 through a wire.

[0022] Among them, the vibrator group 1 is evenly distributed on both sides of the hollow shaft 3; the wire between the brush group 4 and the ultrasonic vibrator 6 is located inside the hollow shaft 3, and the hollow shaft 3 can realize forward and reverse rotation; The outer side is wrapped with an anti-corrosion lay...

Embodiment 2

[0024] On the basis of Embodiment 1, the outer side of the vibrator group 1 can also be treated with anti-corrosion materials, which mainly play a role of anti-corrosion.

[0025] The specific use process of the present invention:

[0026] When in use, the ultrasonic vibrator 6 inside the crystallizer is powered by the brush set 4 and the wire, and the ultrasonic wave generated by the ultrasonic vibrator 6 allows the supersaturated liquid inside the cylinder 5 to be released quickly and uniformly, and the solution in the cylinder 5 is supersaturated The degree can be a cold or heat source from the inside of the cylinder 5, such as an electric heating rod inserted into the cylinder, or a cold or heat source from the outside, such as making a jacket on the equipment housing and passing the heat into the jacket. Steam or circulating cooling water; the hollow shaft 3 can rotate clockwise or counterclockwise to drive the vibrator group 1 to rotate in the cylinder 5, which plays a role o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com