Hollow cathode power converter and control system thereof

A power converter, hollow cathode technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the time delay of heating power output power, complex design, low efficiency and other problems , to achieve the effect of improving the dynamic response of the power supply, the power density and the total efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

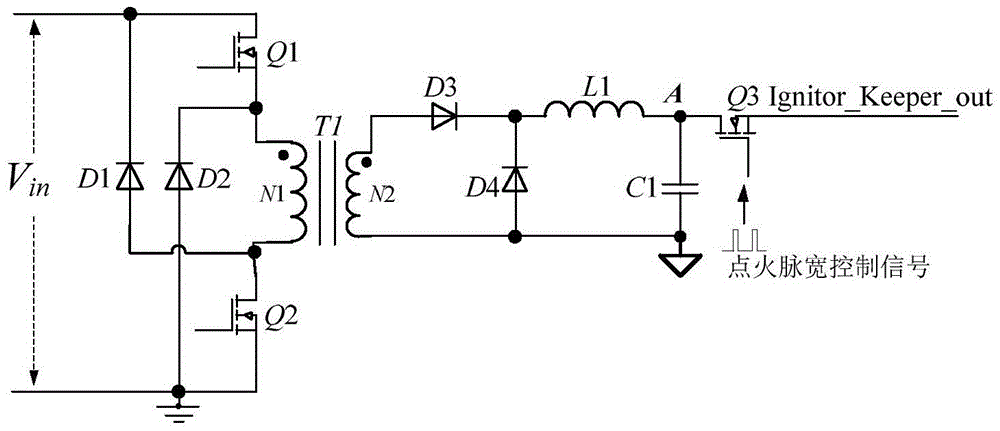

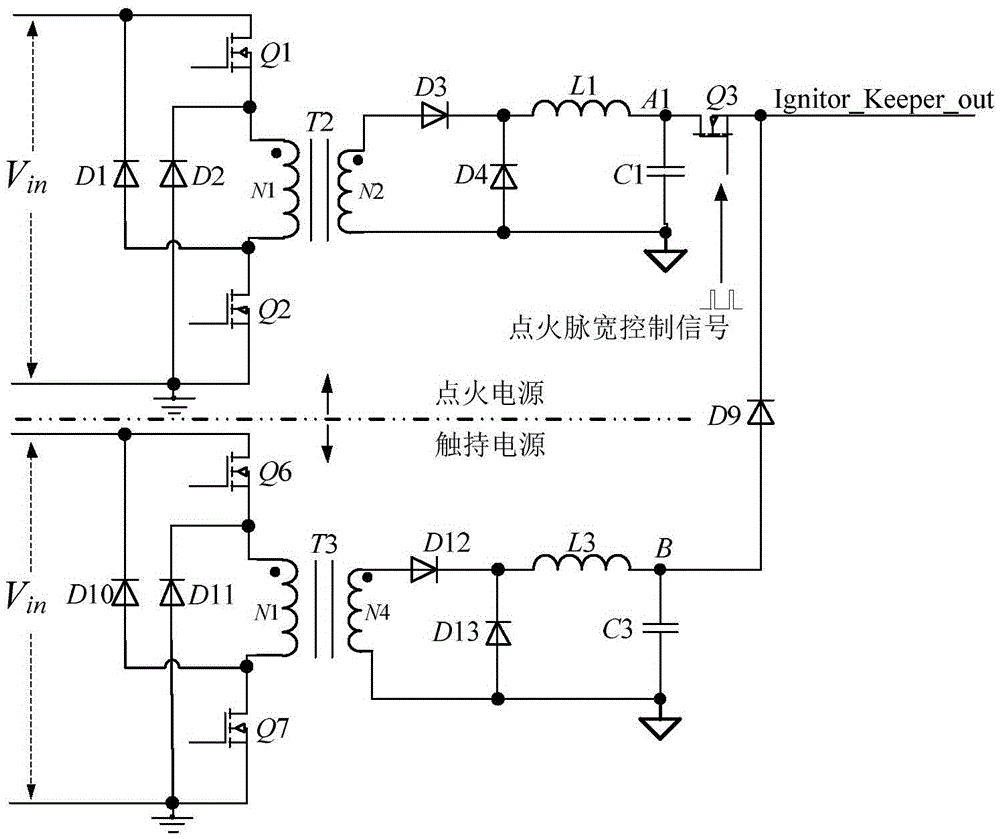

[0034] Such as figure 1 with Figure 6 As shown, this example provides a hollow cathode power converter, including: the main transformer primary circuit and the main transformer secondary rectification and filtering circuit; the main transformer secondary rectification and filtering circuit includes two outputs: heating power output and ignition contact power Output: Sampling the output voltage of the heating power supply of the rectification and filtering circuit on the secondary side of the main transformer to form a closed-loop control of the output voltage, and separately sampling the output current of the heating power supply and the output current of the ignition contact power supply to form a corresponding closed-loop control of the output current loop; in the hollow Before the cathode is successfully ignited, the contact pole and the reference ground present high impedance, the output current loop of the heating power supply works in a closed loop, and the output curr...

Embodiment 2

[0044] Such as Figure 5 As shown, the transformer secondary side rectification filter circuit in this example also includes a heating power supply, the heating power supply includes a diode D5, a diode D6, an inductor L2 and a capacitor C2, and the second end of the secondary side of the transformer T1 with the same name is respectively connected to the The cathode of the diode D6 is connected to one end of the capacitor C2, the second opposite end of the secondary side of the transformer T1 is connected to the cathode of the diode D5, and the anode of the diode D5 and the anode of the diode D6 are respectively grounded through the inductor L2 , the other end of the capacitor C2 is grounded; the output rectification part of the ignition contact power supply is superimposed on the output rectification part of the heating power supply, and the output rectification part of the ignition contact power supply and the output rectification part of the heating circuit adopt the same gr...

Embodiment 3

[0056] This example also provides a control system for a hollow cathode power supply, which includes the hollow cathode power converter described in Embodiment 1 or Embodiment 2, and includes an ignition control circuit 1, a sampling circuit 2 and an ignition variable chopping pulse width Control circuit: the main transformer primary side circuit is connected with the ignition control circuit 1, the ignition control circuit 1 is connected with the main transformer secondary side rectification filter circuit through the sampling circuit 2, and the ignition variable chopping pulse width The control circuit is connected with the rectifying and filtering circuit on the secondary side of the main transformer. Preferably, the ignition variable chopping pulse width control circuit is connected with the secondary rectification and filtering circuit of the main transformer and a chopping switch.

[0057] Such as Figure 10 As shown, the sampling circuit described in this example inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com