Lithium ion battery electrolyte for improving battery pole piece interface

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of lithium-ion separation, black spots, mass transfer and conduction speed reduction, and potential safety hazards in the pole piece, so as to achieve a good negative electrode interface, avoid lithium-ion separation during charging, and reduce The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

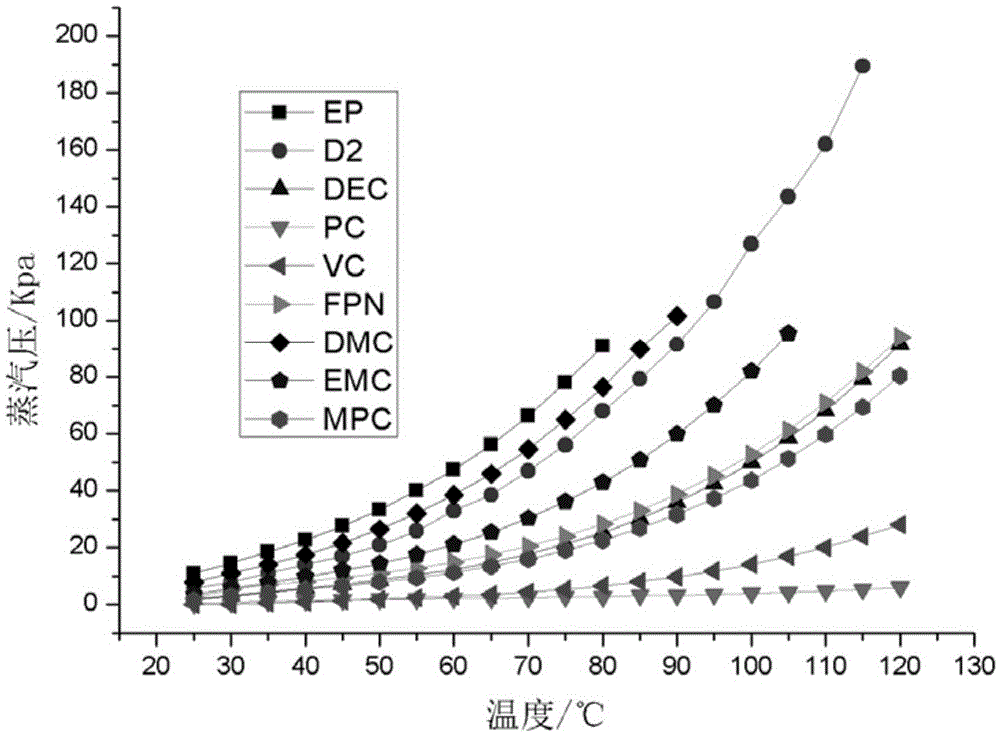

Method used

Image

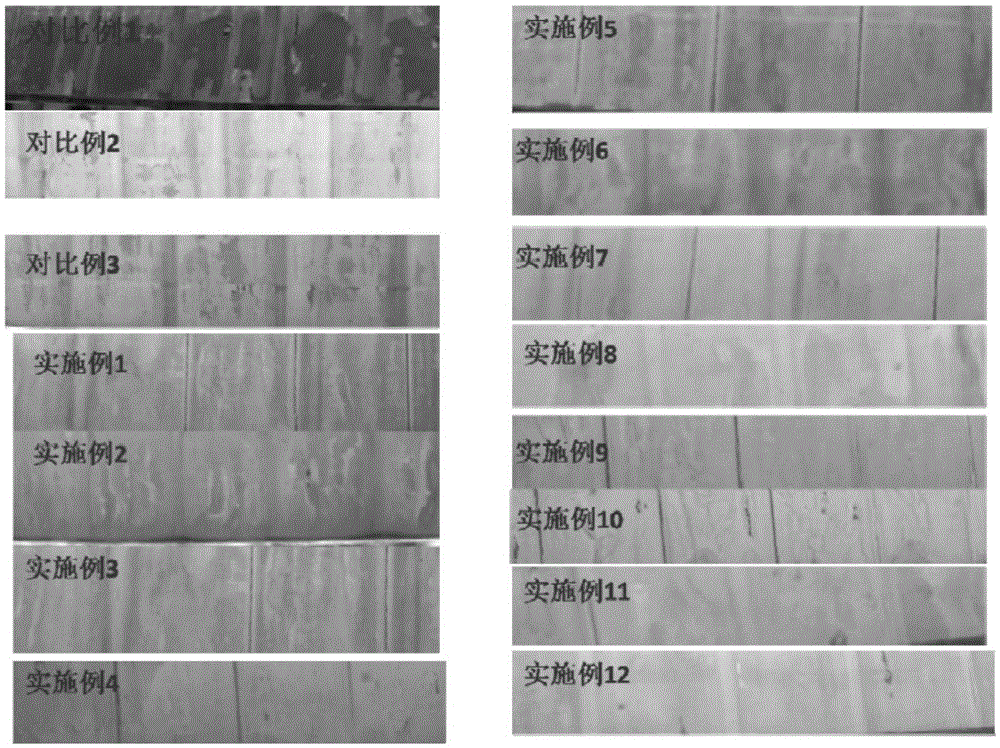

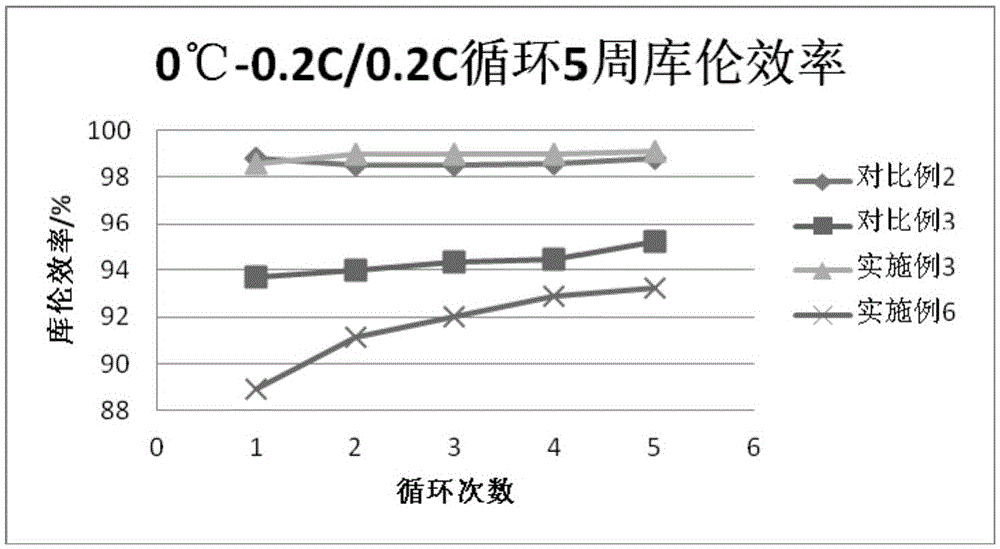

Examples

Embodiment 1

[0039] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 1.

Embodiment 2

[0041] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 2.

Embodiment 3

[0043] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com