Medium and large density battery packing machine

A battery pack and drive motor technology, which is applied in the field of packaging machines, can solve the problems of not being well adapted to medium and large-density batteries, and achieve the effects of good applicability, high production efficiency, and high space occupation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

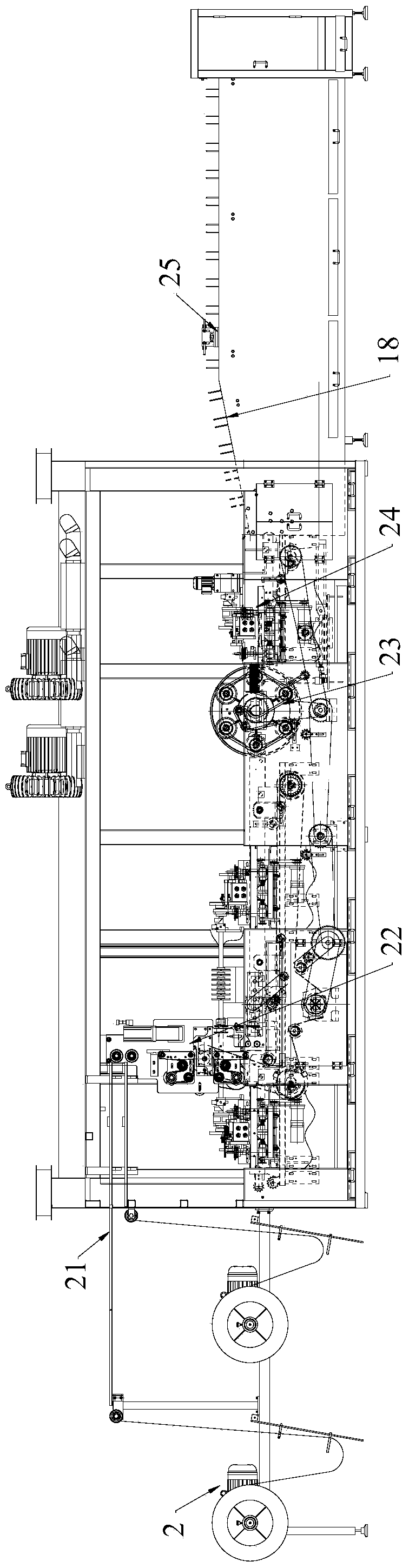

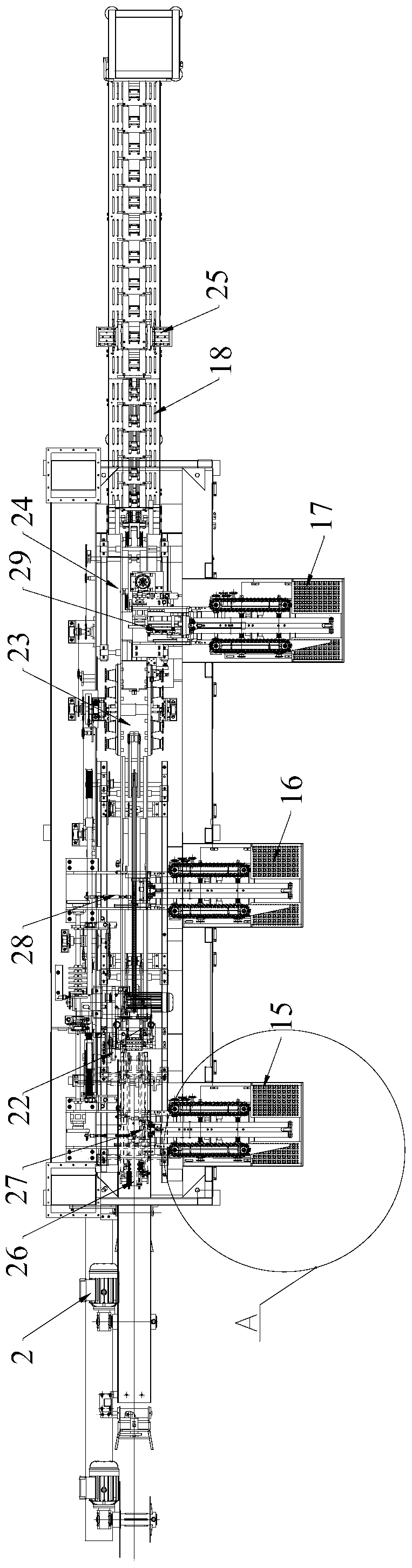

[0050] Below in conjunction with each accompanying drawing, the present invention is described in detail.

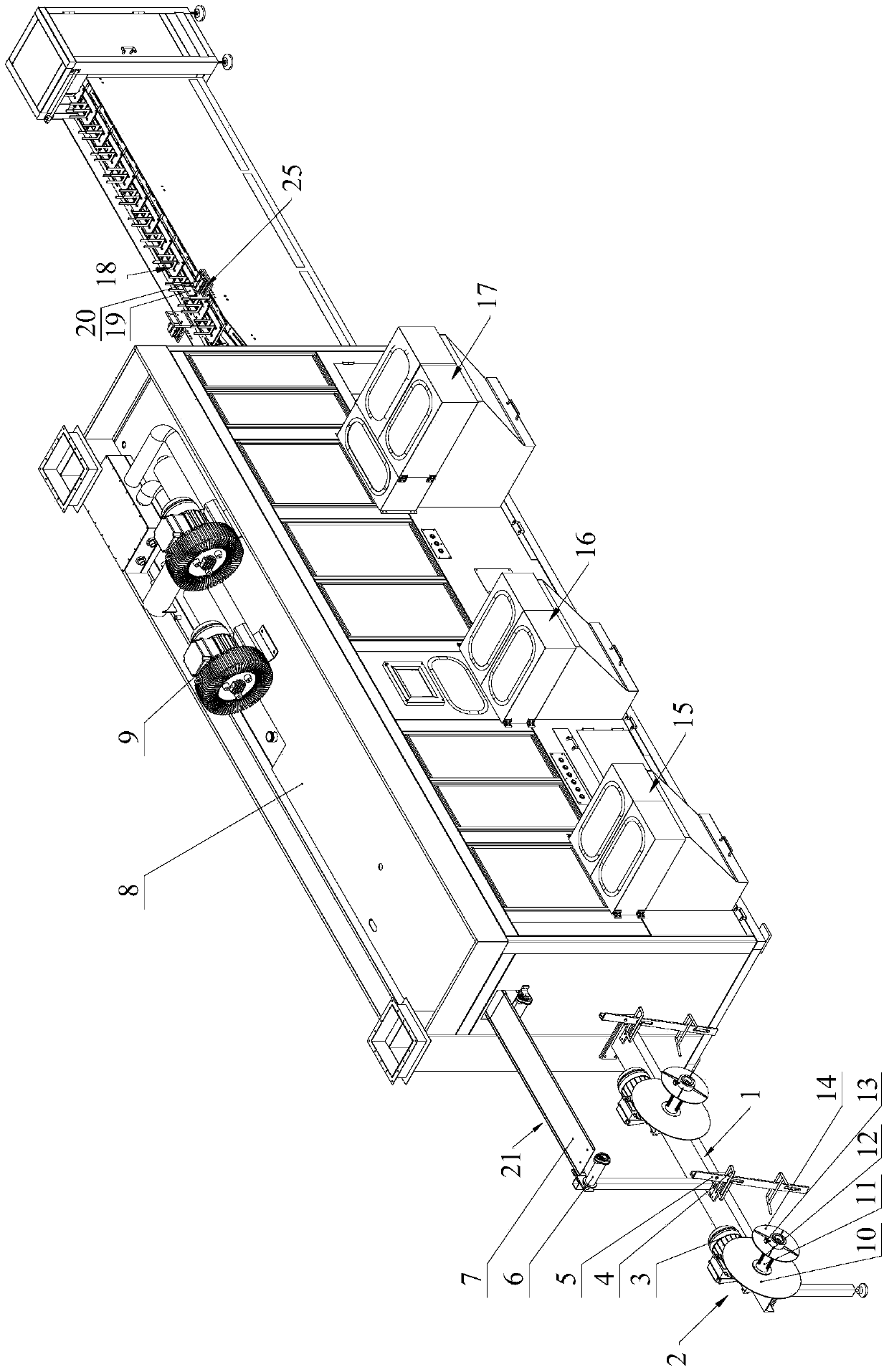

[0051] Such as Figure 1~3 As shown, a medium-to-large-density battery wrapping machine includes a base frame 1, and at least two sets of separator paper unwinding mechanisms 2 arranged side by side are installed on the base frame 1. The separator paper unwinding mechanism 2 includes:

[0052] The rotating shaft 11 is installed in rotation on the base frame 1, and the rotating shaft is used to install the partition paper roll;

[0053] Drive motor 3, used to drive the rotating shaft to rotate;

[0054] The first limiting disc 10 is sleeved on the rotating shaft and relatively fixed to the rotating shaft, and the first limiting disc is adjacent to the driving motor;

[0055] The second limiting disc 14 is sleeved on the rotating shaft and relatively fixed to the rotating shaft by the locking bolt 13, and the second limiting disc is away from the driving motor;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com