In-situ material detection device and method of in-service equipment

A detection device and material technology, applied in the direction of measuring devices, analyzing materials, testing material hardness, etc., can solve problems such as low detection efficiency, large equipment damage, and inability to detect hardness, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

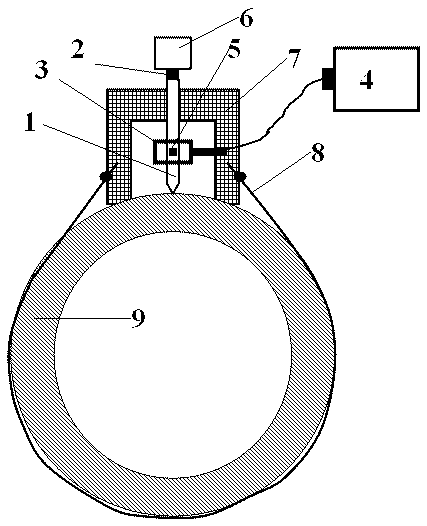

[0018] Examples such as figure 1 As shown, an in-situ material detection device for in-service equipment includes a probe 1, a pressure sensor 2, an eddy current detection probe 3, an eddy current detector 4, a metal induction block 5, a driving pressurization device 6, a bracket 7, and a fixed chain 8 , it is characterized in that: the material hardness of the measuring needle 1 is greater than that of the tested workpiece 9, the upper end surface of the measuring needle 1 is fixedly connected with the sensing surface of the pressure sensor 2, and the measuring needle 1 passes through the center axis through hole at the top of the support 7, which can be Move back and forth along the axial direction of the through hole; the upper end surface of the pressure sensor 2 is fixedly connected with the driving and pressing device 6; the metal sensing block 5 is fixed on the rod of the probe 1, and the material of the metal sensing block 5 is consistent with the probe 1. The material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com