Lamp holder rotating structure and LED lamp

A technology of lamp head rotation and lamp head cover, applied in the field of lighting, can solve the problems of relative distance change, non-compliance with the detection standard of LED lamps, etc., and achieve the effect of meeting the detection standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problem solved by the present invention, the technical solution adopted and the technical effect achieved clearer, the following technical solutions are adopted:

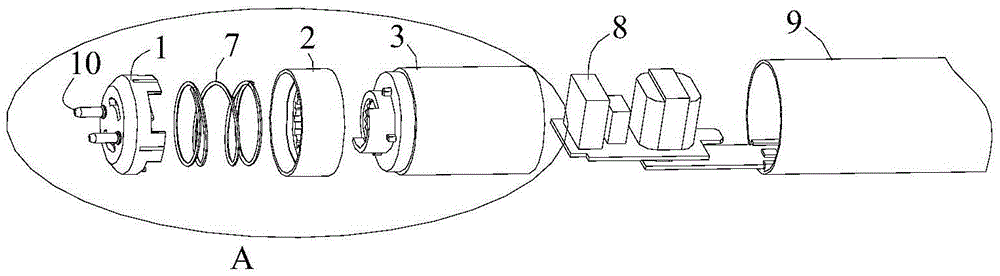

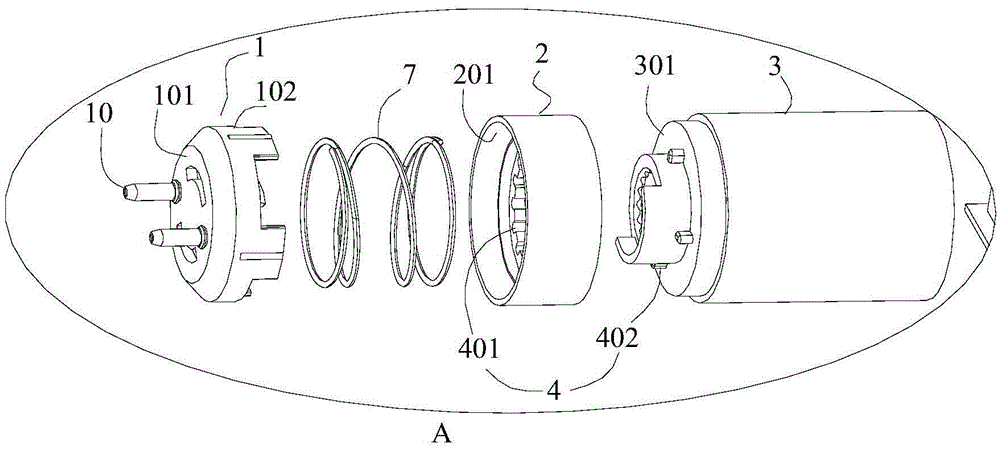

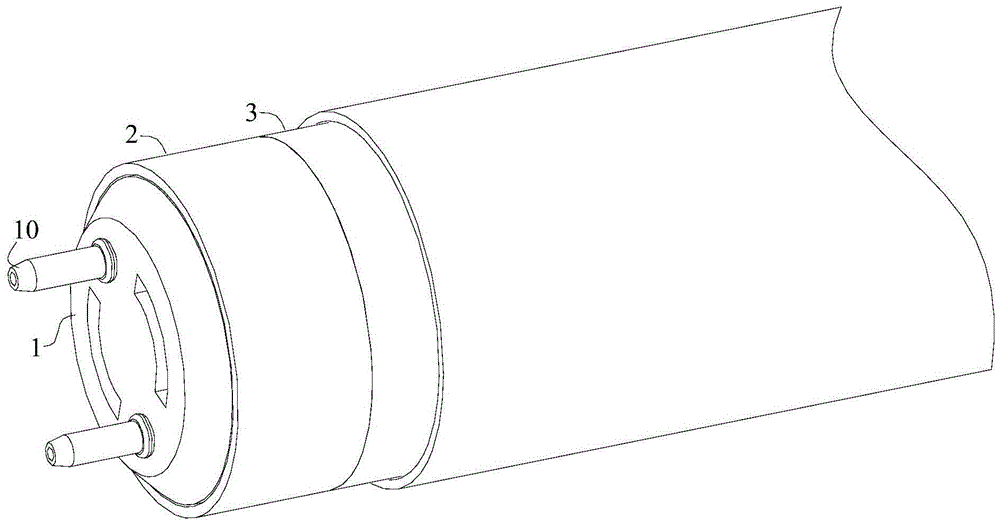

[0031] Please refer to Figure 1 to Figure 18 . refer to Figure 1 to Figure 3 , the first embodiment of the present invention provides a lamp holder rotating structure, including lamp cap 1, dial 2 and power supply compartment 3; lamp cap 1 and dial 2 are slidably connected; lamp cap 1 and power supply compartment 3 are rotatably connected , the dial 2 and the power supply compartment 3 are limited by the first positioning structure 4, and the first positioning structure 4 includes a first tooth slot 401 and a first positioning protrusion 402 that is clamped into the first tooth slot 401;

[0032] refer to Figure 4 and Figure 5 , when the dial 2 is close to the power supply compartment 3, the first positioning protrusion 402 is stuck into the first tooth slot 401, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com