Multi-cylinder two-stage variable-capacity compressor system and control method of switching of running modes thereof

A technology of variable capacity compressors and compressors, which is applied in the fields of compressors, refrigeration and air conditioning, and can solve problems such as refrigerant leakage, increased power consumption, and decreased compressor capacity, and achieve reduced capacity output, reduced leakage losses, and high Effects on capacity and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

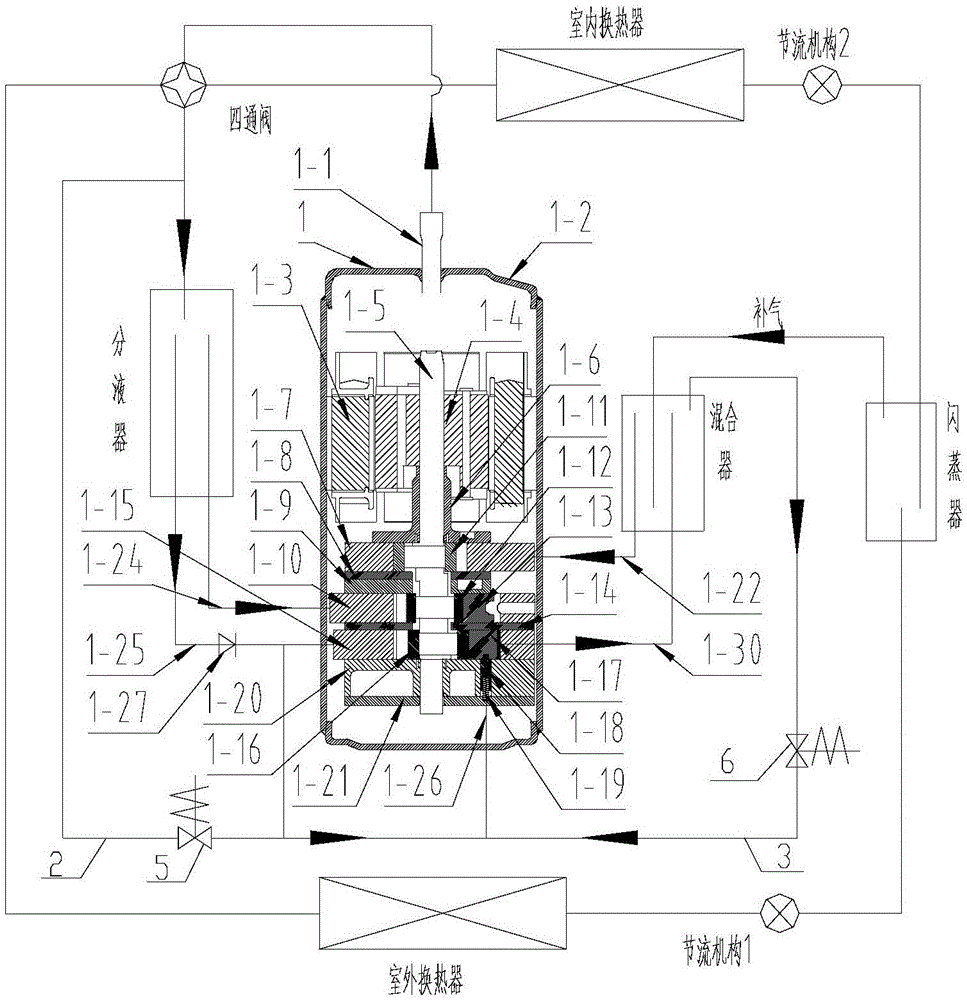

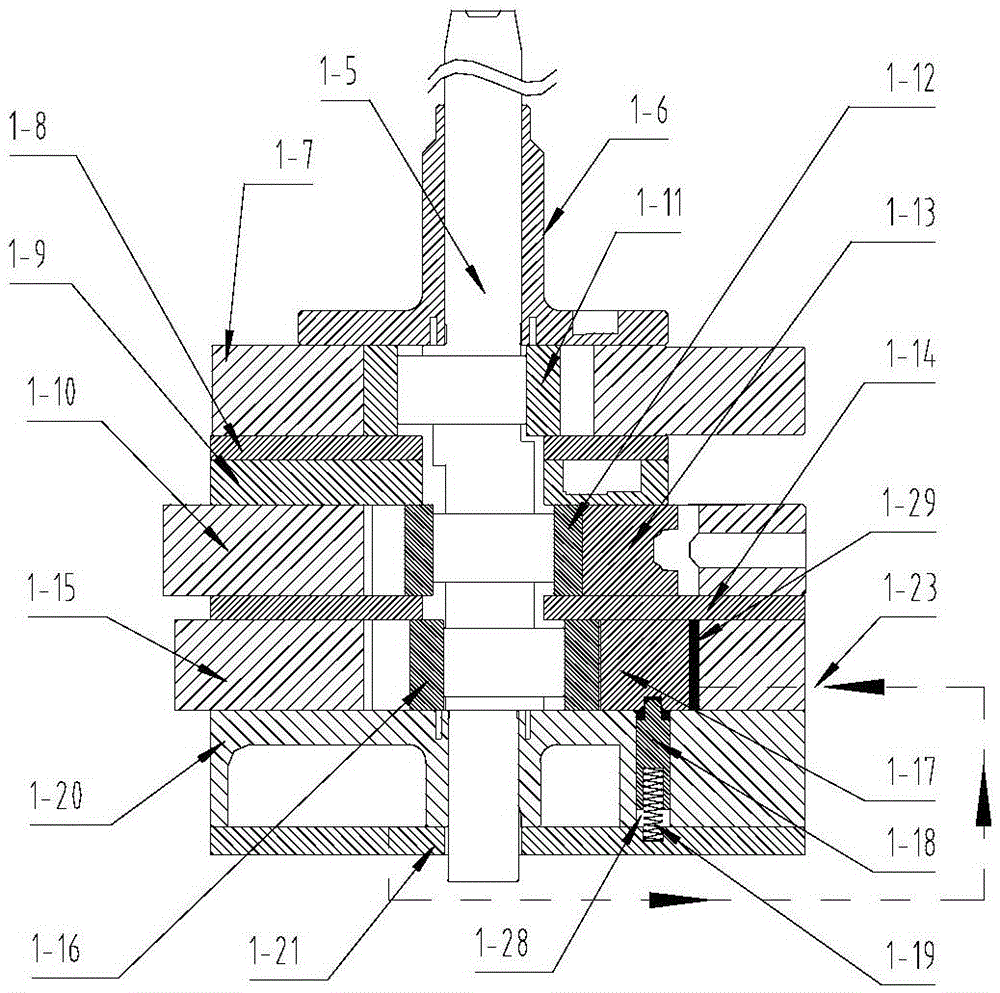

[0061] Such as figure 1 , a compression part provided with a variable volume mechanism includes a cylinder 1-15, a roller 1-16, a slide plate 1-17, and a pressure chamber 1-29 arranged on the tail side of the slide plate 1-17 and a pin 1-17 The back pressure chamber 1-28 of 18 lower ends. The pressure chamber 1-29 communicates with the first-stage exhaust through the pressure channel 1-23 (consisting of the lower flange, the lower flange cover plate and the internal channel or external pipeline of the cylinder), and its internal pressure is always maintained at the intermediate pressure ( See image 3 ), the exhaust channel 1-30 communicates with the mixer through the pipeline, and the exhaust of the low-pressure stage cylinder 1 and the low-pressure stage cylinder 2 is connected to the suction of the high-pressure stage cylinder 1-7 through the mixer and the suction pipe 1-22 of the high-pressure stage cylinder. breath. The pressure switching of the control chamber at the ...

Embodiment 2

[0069] Such as Figure 4 , a compression part provided with a variable volume mechanism includes a cylinder 1-15, a roller 1-16, a slide plate 1-17, and a pressure chamber 1-29 arranged on the tail side of the slide plate 1-17 and a pin 1-17 The back pressure chamber 1-28 of 18 lower ends. The pressure chamber 1-29 communicates with the first-stage exhaust through the pressure channel 1-23 (consisting of the lower flange, the lower flange cover plate and the internal channel or external pipeline of the cylinder), and its internal pressure is always maintained at the intermediate pressure ( See image 3 ); the exhaust channel 1-30 of the low-pressure stage cylinder is formed by the internal channel or external pipeline of the pump body partition and the cylinder. The pressure switching of the control chamber at the lower end of the pin is realized by two solenoid valves (the first solenoid valve 5 and the second solenoid valve 6).

[0070] There is also a bypass branch conne...

Embodiment 3

[0075] See Figure 5 and Figure 6 , a compression part provided with a variable volume mechanism includes a cylinder 1-15, a roller 1-16, a slide plate 1-17, and a pressure chamber 1-29 arranged on the tail side of the slide plate 1-17 and a pin 1-17 The back pressure chamber 1-28 of 18 lower ends. The pressure chamber 1-29 communicates with the first-stage exhaust through the pressure channel 1-23 (consisting of the lower flange, the lower flange cover plate and the internal channel or external pipeline of the cylinder), and its internal pressure is always maintained at the intermediate pressure ( See image 3), the exhaust channel 1-30 communicates with the mixer through the pipeline, and the exhaust of the low-pressure stage cylinder 1 and the low-pressure stage cylinder 2 is connected to the suction of the high-pressure stage cylinder 1-7 through the mixer and the suction pipe 1-22 of the high-pressure stage cylinder. breath. The pressure switching of the control cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com