Gas production control method for natural gas well and intelligent controller

A technology of intelligent controller and control method, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. The method is simple and other problems, to achieve the effect of easy analysis and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a gas production control method for a natural gas well, and the control method mainly includes the following steps:

[0032] (1) The steps of presetting control valve opening data corresponding to different casing pressures, oil pressures and flow rates of gas wells;

[0033] (2) The steps of collecting gas well casing pressure, oil pressure and flow data;

[0034] (3) According to the collected casing pressure, oil pressure and flow data, control the corresponding opening of the control valve.

[0035] Wherein, in step (1), the opening degree of the control valve corresponding to the corresponding casing pressure, oil pressure and flow data is not uniquely determined, and the opening degree of the control valve corresponding to different casing pressure, oil pressure and flow rate of the gas well is preset. The data can be set according to the actual working conditions. The collection of gas well casing pressure, oil pressure, and flow...

Embodiment 2

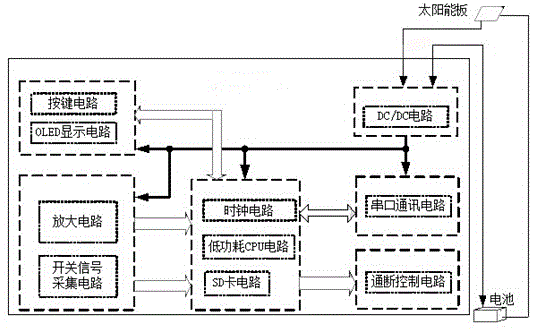

[0040] like figure 1 As shown, this embodiment provides an intelligent controller, and the controller is used to implement the gas production control method for a natural gas well disclosed in Embodiment 1. The intelligent controller mainly includes six units, which are as follows: signal acquisition unit, processing unit, control unit, communication unit, human-computer interaction unit and power supply unit. Among them, the signal acquisition unit, the control unit, the communication unit, and the human-computer interaction unit are all connected with the processing unit to realize communication, and the power supply unit provides power for the work of each unit.

[0041] In order to make those skilled in the art have a clearer understanding and understanding of the intelligent controller, each unit is described in detail below:

[0042] The signal acquisition unit is mainly used to collect gas well casing pressure, oil pressure, flow data, and control valve status data; sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com