Electrochemical preparation method of black phosphorus quantum dots

A black phosphorus quantum and electrochemical technology, applied in the field of nanomaterial preparation, can solve the problems of time-consuming and energy-consuming, low yield, difficult to control the size of quantum dots, etc., achieve uniform size, high scalability, and avoid insufficient ultrasonic energy efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) First, the black phosphorus crystal was fixed on a metal rod with conductive glue as a working electrode, and a platinum electrode was used as a counter electrode. The two were placed in an organic solvent containing an electrolyte, and the temperature of the solvent was kept at 10°C. The organic solvent used is N,N-dimethylformamide (DMF), and the electrolyte is 0.5M lithium chloride.

[0018] (2) Then connect the working electrode and the counter electrode to the positive and negative poles of the DC power supply respectively, apply a voltage of 7V, use the electrolyte ions to migrate to the black phosphorus crystal and undergo electrochemical intercalation reaction, resulting in the decomposition of the black phosphorus crystal to form quantum dot dispersion liquid.

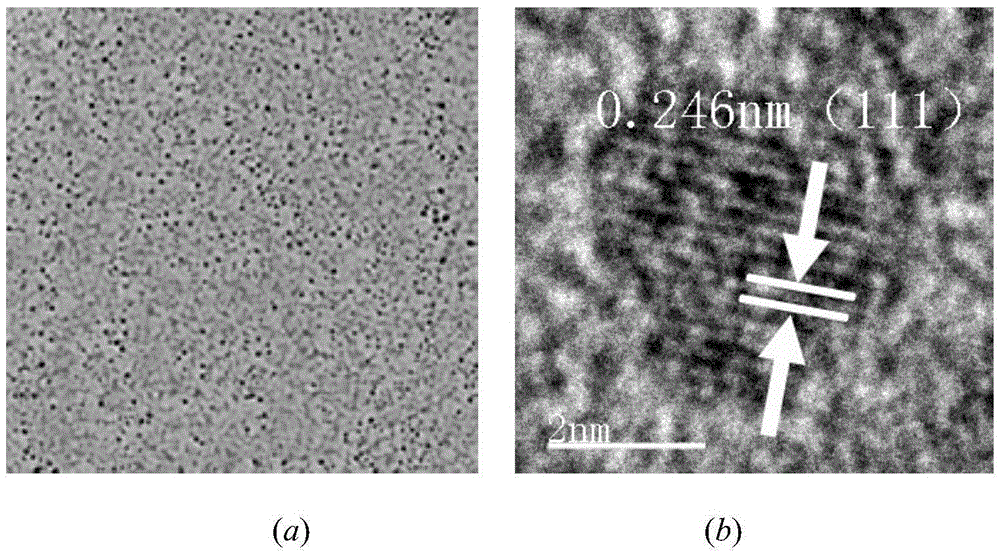

[0019] (3) Centrifuge the obtained black phosphorus quantum dot dispersion at a rotational speed of 1500 rpm, and take the stable supernatant to obtain quantum dots with an average diameter of 3 nm....

Embodiment 2

[0021] (1) First, the black phosphorus crystal was fixed on the metal rod with conductive glue as the working electrode, and the platinum electrode was used as the counter electrode. The two were placed in an organic solvent containing electrolyte, and the temperature of the solvent was kept at 20 °C. The organic solvent used is N,N-dimethylformamide (DMF), and the electrolyte is 1M lithium chloride.

[0022] (2) Then connect the working electrode and the counter electrode to the positive and negative poles of the DC power supply respectively, apply a voltage of 10V, use the electrolyte ions to migrate to the black phosphorus crystal and undergo electrochemical intercalation reaction, resulting in the decomposition of the black phosphorus crystal to form quantum dot dispersion liquid.

[0023] (3) Centrifuge the obtained black phosphorus quantum dot dispersion at a rotational speed of 1500 rpm, and take the stable supernatant to obtain quantum dots with an average diameter of ...

Embodiment 3

[0025] (1) First, the black phosphorus crystal was fixed on the metal rod with conductive glue as the working electrode, and the platinum electrode was used as the counter electrode. The two were placed in an organic solvent containing electrolyte, and the temperature of the solvent was kept at 35 °C. The organic solvent used is N,N-dimethylformamide (DMF), and the electrolyte is 1.5M lithium chloride.

[0026] (2) Then connect the working electrode and the counter electrode to the positive and negative poles of the DC power supply respectively, apply a voltage of 12V, use the electrolyte ions to migrate to the black phosphorus crystal and undergo electrochemical intercalation reaction, resulting in the decomposition of the black phosphorus crystal to form quantum dot dispersion liquid.

[0027] (3) Centrifuge the obtained black phosphorus quantum dot dispersion at a rotational speed of 1500 rpm, and take the stable supernatant to obtain quantum dots with an average diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com