Metal plasma source and application thereof

A plasma source and metal technology, applied in the field of ion source, can solve the problems of low beam density, difficulty in stable discharge, high ignition pressure and working pressure, etc., and achieve the effects of increasing electron concentration, reducing electron escape, and reducing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

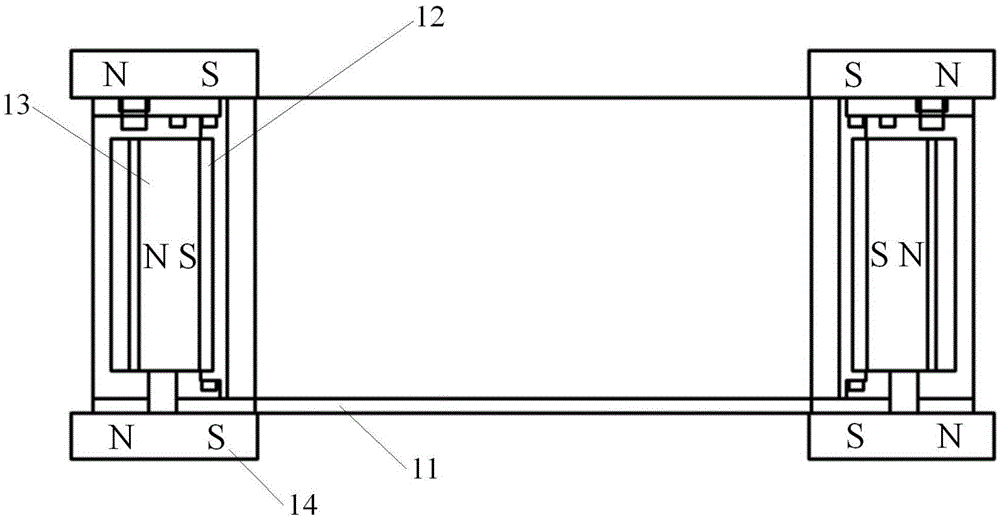

[0035] The metal plasma source of this example, such as figure 1As shown, it includes a housing 11 , a magnetron target 12 , a magnetic element 13 and a suppression magnetic element 14 . The casing 11 is in the shape of a hollow cylinder, and the magnetron target 12 is laid in the hollow inner cavity of the casing 11, and is not connected to the casing 11. The magnetic element 13 is laid between the magnetron target 12 and the casing 11, and suppresses the magnetic element 14 are mounted on both ends of the magnetic element 13 in pairs, and the magnetic element 14 is suppressed to have the same polarity as the ends of the magnetic element 13 . figure 1 Among them, N and S represent the N pole and S pole of the magnet respectively, and the suppression of the polarity of the magnetic element 14 and the end of the magnetic element 13 means that the direction of the N pole and the S pole of the suppression magnetic element 14 and the magnetic element 13 are the same, such as f...

Embodiment 2

[0044] The metal plasma source of this example is the same as that of Embodiment 1, except that the suppression magnetic element 44 is installed inside the casing 41, as Figure 4 shown. In addition, the suppressing magnetic element 44 of this example is a permanent magnet of FeCrCo permanent magnet alloy, with a strength of 50 mT, a length of 40 mm, and a width and a height of 5 mm. The rest, including the installation of the magnetron target 42, the magnetic element 43, etc., are the same as those in the first embodiment. Figure 4 N and S represent the N pole and S pole of the magnet, respectively.

[0045] When the metal plasma source of this example is in use, its additionally installed suppression magnetic element 44 can also reduce the escape of electrons, so that more electrons stay inside the metal plasma source, which can reduce working conditions and improve sputtering materials. ionization rate and target utilization.

Embodiment 3

[0047] This example is the same as the metal plasma source in Embodiment 1, except that an auxiliary ionization discharge device is added on the metal plasma source, such as Figure 5 As shown, in this example a microwave device 55 is added to the metal plasma source. The rest, including the installation of the housing 51 , the magnetron target 52 , the magnetic element 53 and the suppressing magnetic element 54 , are the same as those in the first embodiment. Figure 5 N and S represent the N pole and S pole of the magnet, respectively.

[0048] A microwave device 55 is installed in the metal plasma source of this example as an auxiliary ionization discharge device to further increase the ionization rate of the sputtered material. At the same time, suppressing the magnetic element 54 reduces electron escape, so that more electrons stay inside the metal plasma source, while reducing working conditions, it also increases the ionization rate of the sputtering material and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com