Submarine seamless line pipe above 415SPDF steel grade having large strain resistance

A technology of seamless line pipe and large strain resistance, which is applied in the field of seamless line pipe of steel grade above 415SPDF to achieve good welding performance, good use effect, and the effect of meeting the requirements of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

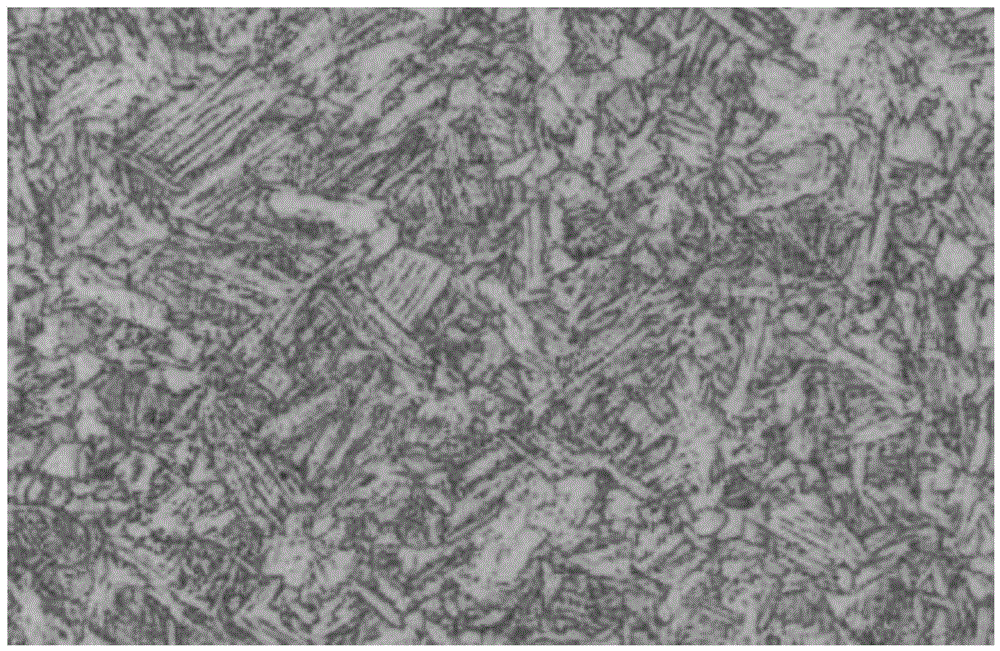

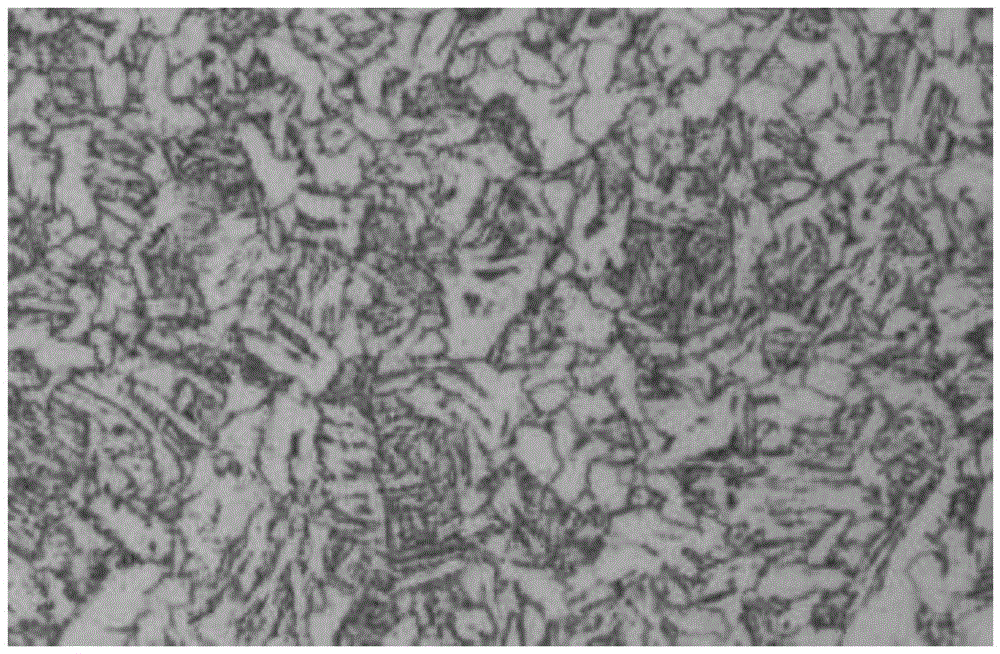

[0011] The seabed seamless line pipe of steel grade above 415SPDF with large strain resistance performance of the present invention is described in conjunction with the accompanying drawings.

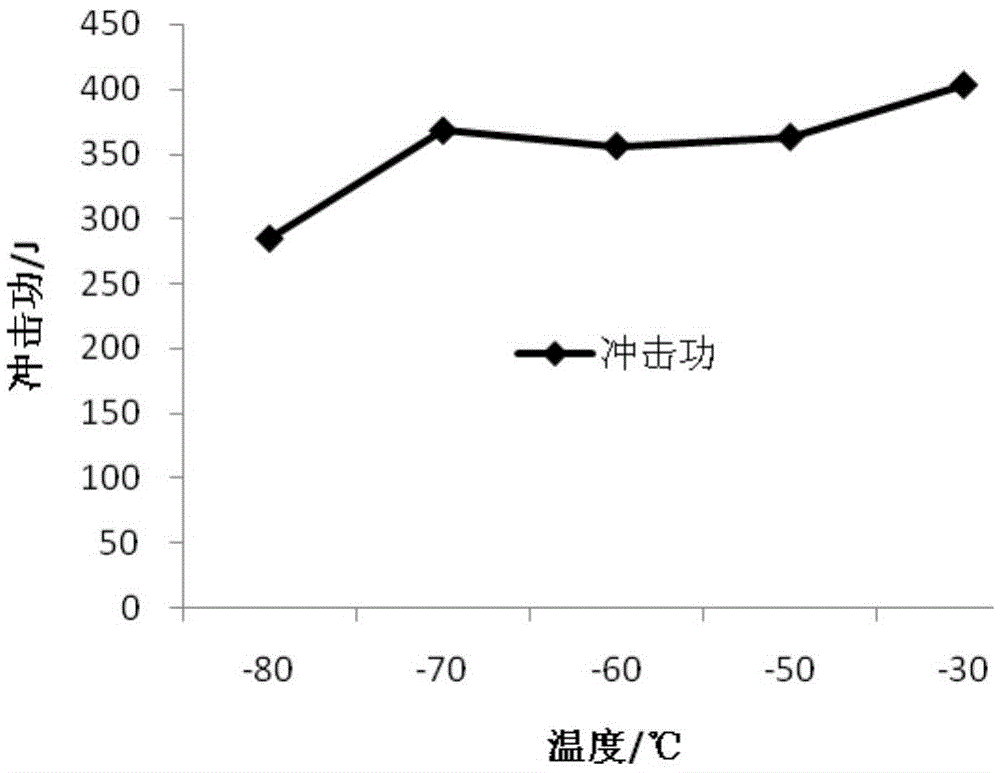

[0012] The design concept of the 415SPDF and above steel grade seabed seamless line pipe with large strain resistance performance of the present invention is based on the oil and gas development industry trend, and the performance requirements of large strain resistance line pipes necessary for the gradual exploitation of oceans and deep seas. Composition design and performance optimization meet the high strain resistance, high impact toughness and high corrosion resistance required by the construction method R-lay for pipes.

[0013] The seabed seamless line pipe of steel grade above 415SPDF with large strain resistance of the present invention has components by weight of 0.05-0.11% of C, 0.20-0.40% of Si, 1.0-1.40% of Mn, P≤0.010%, S≤0.002%, Ni0.05~0.30%, Cr0.05~0.30%, Mo0.05~0.30%, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com