Inorganic Metal Composite Hydrophobic Film

An inorganic metal and thin film technology, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of inorganic coating and other problems, and achieve the effect of basically no change in size, high hardness and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

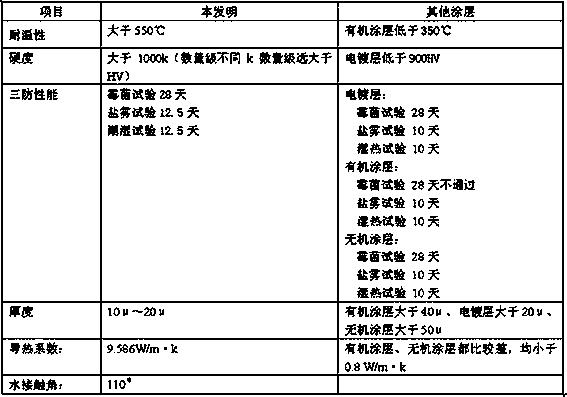

Image

Examples

Embodiment 1

[0011] Example 1: Inorganic metal composite hydrophobic film, made of raw materials with the following mass ratios, aluminum powder 13%, lithium oxide 5%, titanium powder 44%, carbon powder 8%, iron powder 18%, silicon dioxide 12% The production process steps are as follows: silicon dioxide, titanium powder, carbon powder and iron powder are mixed in a high temperature furnace and heated to 2600 °C for melting to obtain a melt, then cooled to 2000 °C, and added in proportion to the melt. The aluminum powder and lithium oxide are stirred and melted to make the melt evenly mixed, then continue to heat up to 2400℃ and stir to make the melt evenly dispersed, then cool down and stir to 500℃~600℃ to make the melt into a uniform powder; use boron as auxiliary agent, argon The gas is a protective gas, the workpiece is placed in a high temperature furnace of 500℃~600℃, and the surface of the workpiece is sprayed to form an inorganic metal composite hydrophobic film. The auxiliary agent...

Embodiment 2

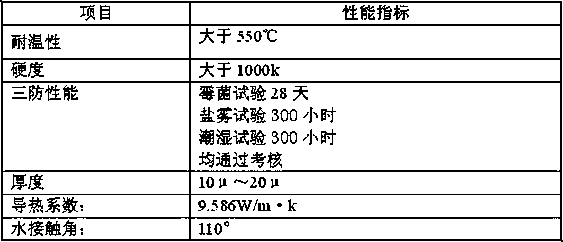

[0014] Example 2: Inorganic metal composite hydrophobic film, made of raw materials with the following mass ratios: aluminum powder 17%, lithium oxide 1%, titanium powder 43%, carbon powder 12%, iron powder 17%, silicon dioxide 10% ; Its production process method is with embodiment 1, and each performance index is shown in Table 2.

[0015] Table 2 Various performance indexes of inorganic metal composite hydrophobic films

[0016]

Embodiment 3

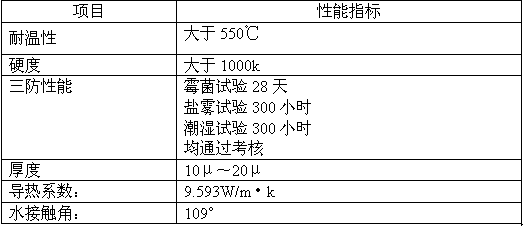

[0017] Example 3: An inorganic metal composite hydrophobic film, made of raw materials with the following mass ratios: aluminum powder 15%, lithium oxide 4%, titanium powder 47%, carbon powder 11%, iron powder 15%, silicon dioxide 8%; its production process method is the same as that of Example 1, and each performance index is shown in Table 3.

[0018] Table 3 Various performance indexes of inorganic metal composite hydrophobic films

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com