Anti-fog coating composition, prepared optical film and display device with optical film

An anti-fog coating and composition technology, applied in optics, optical components, coatings, etc., can solve the problems of lower light transmittance of substrates, occurrence of danger, and impact on sight, and achieve excellent water resistance and scratch resistance, and prolong Timeliness and the effect of increasing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

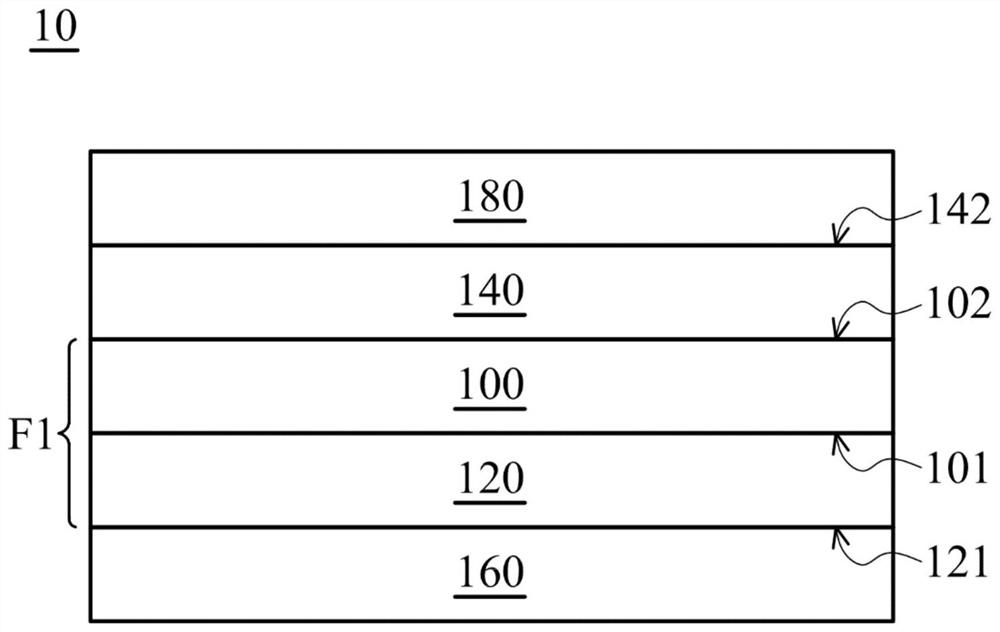

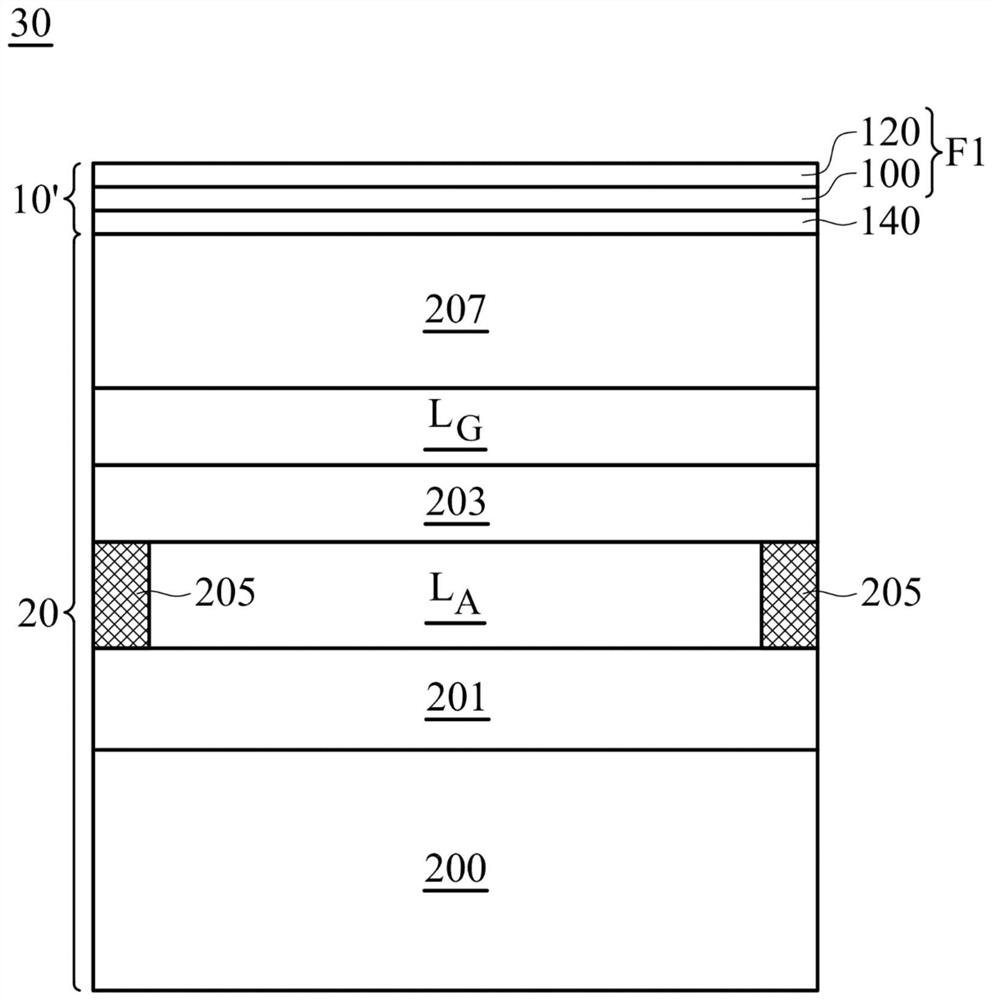

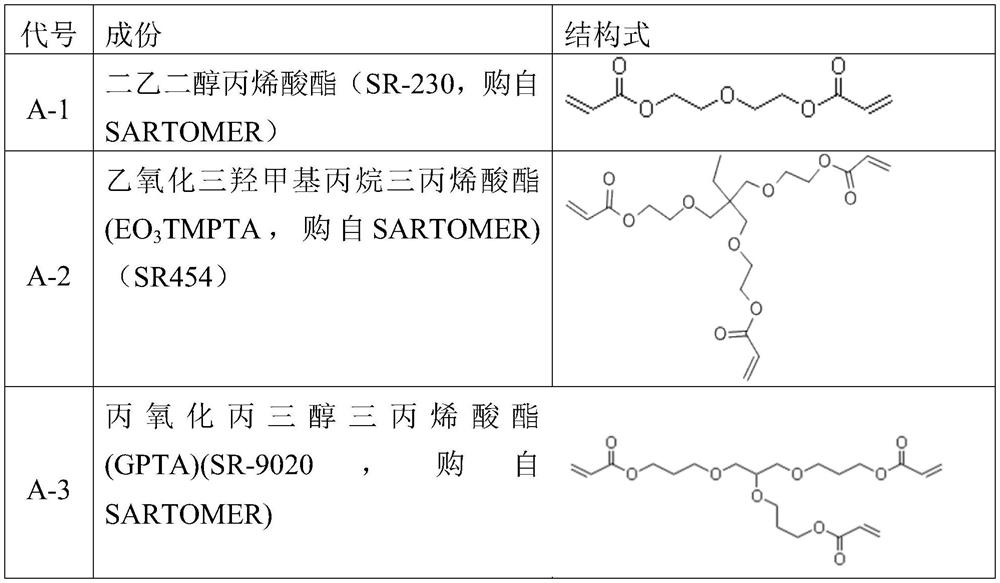

Embodiment Construction

[0022] In order to prevent the surface of the substrate from fogging, there are generally two methods. The first method is to eliminate water vapor or temperature difference. Although it is difficult to eliminate water vapor in the air, the surface temperature of the substrate is always higher than the dew point of the water vapor by means of heating, such as power heating or infrared radiation. However, these The heating method is expensive and energy-intensive. The second method is to change the wettability of the substrate surface, such as making the substrate surface hydrophilic or hydrophobic. When the surface of the substrate is hydrophilic, the contact angle of the surface of the substrate to water can be reduced, so that the small water droplets condensed on the surface will not form tiny water droplets, but spread on the surface to form a film, reducing the diffusion of light, This ensures the transparency of the material. In addition, if a layer of hydrophobic subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com