Nitric oxide (NOx) control method based on inhibiting fuel nitrogen conversion during iron ore sintering process

A technology of sintering process and control method, applied in the field of iron and steel metallurgy, can solve the problems of increasing the cost of additives, unsatisfactory emission reduction efficiency, affecting the quality indicators of sintered minerals, etc. beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

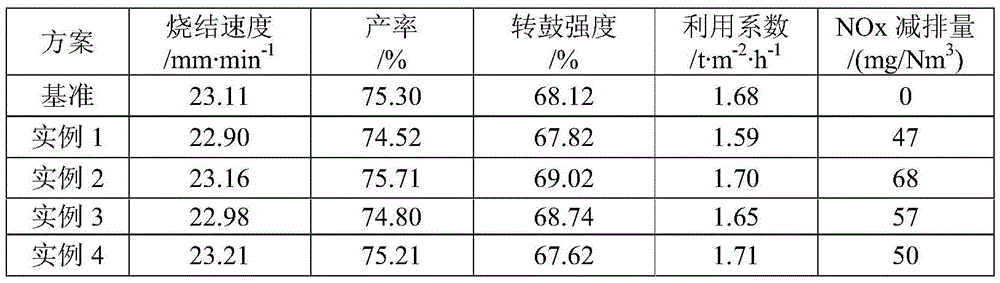

Examples

Embodiment 1

[0021] A kind of NOx control method based on suppressing iron ore sintering process fuel nitrogen conversion of the present invention comprises the following steps:

[0022] (1) Firstly, sieve out -1mm sintered return ore;

[0023] (2) Weigh the coke powder, and add the -1mm sintered ore sieved in step (1) into the coke powder (the quality of the -1mm sintered ore is 1.5 times the quality of the coke powder); 20% of hematite concentrate is added (the mass content of -0.074mm concentrate in hematite concentrate accounts for 75%, and SiO in hematite concentrate 2 Content is 4%) mixing; adding quicklime to adjust the alkalinity of the mixture composed of fine-grained hematite and quicklime to be 2.4; finally add sucrose (the addition of sucrose is between the quality of coke powder, -1mm sintered return ore and hematite concentrate and 0.3%), carry out pre-granulation in the cylinder mixer after the above material batching, obtain the pre-granulation mixture;

[0024] (3) Perfo...

Embodiment 2

[0027] A kind of NOx control method based on suppressing iron ore sintering process fuel nitrogen conversion of the present invention comprises the following steps:

[0028] (1) Firstly, sieve out -1mm sintered return ore;

[0029] (2) Weigh the coke powder, and add the -1mm sintered ore sieved out in step (1) into the coke powder (the quality of the -1mm sintered ore is 3.0 times the quality of the coke powder); 40% of hematite powder ore is added (the quality content of -0.5mm powder ore in hematite powder ore accounts for 60%, and SiO in hematite powder ore 2content of 6.0%); add quicklime to adjust the alkalinity of the mixture composed of fine-grained hematite and quicklime to be 2.0; finally add starch (the amount of starch added is equal to the quality of coke powder, -1mm sintered return ore and hematite powder ore) and 0.2%), carry out pre-granulation in the cylinder mixer after the above material batching, obtain the pre-granulation mixture;

[0030] (3) Perform co...

Embodiment 3

[0033] A kind of NOx control method based on suppressing conversion of fuel nitrogen in sintering process of the present invention comprises the following steps:

[0034] (1) Firstly, sieve out -1mm sintered return ore;

[0035] (2) Weigh the coke powder, and add the -1mm sintered ore sieved in step (1) into the coke powder (the quality of the -1mm sintered ore is 2.5 times the quality of the coke powder); 30% of hematite powder ore is added (the quality content of -0.5mm powder ore in hematite powder ore accounts for 55%, and SiO in hematite powder ore 2 content of 5.0%); add quicklime to adjust the alkalinity of the mixture composed of fine-grained hematite and quicklime to be 2.2; finally add Palido (the addition amount of Palido is coke powder, -1mm sintered return ore and hematite powder ore 0.1% of the sum of the mass), the above materials are pre-granulated in a drum mixer after batching to obtain a pre-granulated mixture;

[0036] (3) Perform conventional granulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com