Method for producing biogas by enhancing kitchen waste anaerobic fermentation

A technology of kitchen waste and anaerobic fermentation, applied in the directions of fermentation, waste fuel, etc., can solve the problems of reducing the efficiency and economic benefits of anaerobic digestion system, restricting the development of kitchen waste biogas projects, and difficult to operate stably, avoiding trace Insufficient iron, the effect of promoting activity and increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

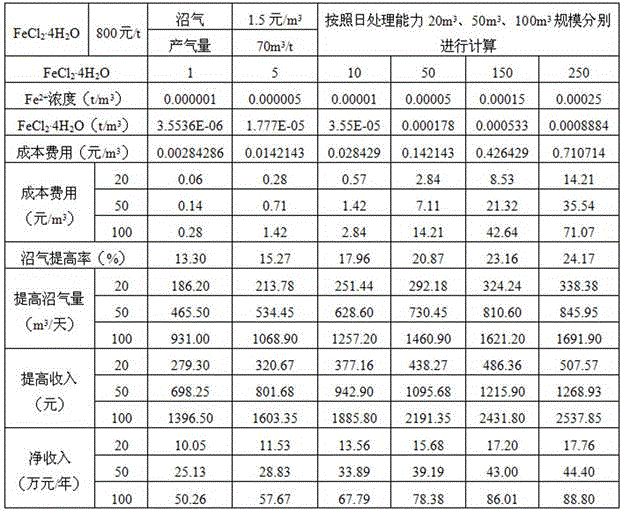

Examples

Embodiment 1

[0018] A method for improving the anaerobic fermentation of kitchen waste to produce biogas, comprising the following steps:

[0019] (1) Weigh the kitchen waste to control the concentration of volatile solids at 15%.

[0020] (2) Weigh the inoculum so that the concentration of volatile solids is controlled at 1.5%.

[0021] (3) Mix the above-mentioned food waste with the above-mentioned inoculum, stir evenly to form a fermentation system, add it into a fermentation bottle, and control the concentration of total volatile solids in the fermentation system at 3%.

[0022] (4) Weigh the water-soluble ferrous salt, add water, and prepare a solution with a ferrous ion concentration of 1000 mg / L.

[0023] (5) Add the ferrous ion solution prepared above into the fermentation bottle in step (3) according to the addition amount of 1 mg per liter.

[0024] (6) Put the fermentation bottle in step (5) in a water bath, ferment at medium temperature (35°C) for 32 days, and collect biogas....

Embodiment 2

[0027] A method for improving the anaerobic fermentation of kitchen waste to produce biogas, comprising the following steps:

[0028] (1) Weigh the kitchen waste to control the concentration of volatile solids at 15%.

[0029] (2) Weigh the inoculum so that the concentration of volatile solids is controlled at 1.5%.

[0030] (3) Mix the above-mentioned food waste with the above-mentioned inoculum, stir evenly to form a fermentation system, add it into a fermentation bottle, and control the concentration of total volatile solids in the fermentation system at 3%.

[0031] (4) Weigh the water-soluble ferrous salt, add water, and prepare a solution with a ferrous ion concentration of 1000 mg / L.

[0032] (5) Add the ferrous ion solution prepared above into the fermentation bottle in step (3) according to the addition amount of 5 mg per liter.

[0033] (6) Put the fermentation bottle in step (5) in a water bath, ferment at medium temperature (35°C) for 32 days, and collect biogas....

Embodiment 3

[0036] A method for improving the anaerobic fermentation of kitchen waste to produce biogas, comprising the following steps:

[0037] (1) Weigh the kitchen waste to control the concentration of volatile solids at 15%.

[0038] (2) Weigh the inoculum so that the concentration of volatile solids is controlled at 1.5%.

[0039] (3) Mix the above-mentioned food waste with the above-mentioned inoculum, stir evenly to form a fermentation system, add it into a fermentation bottle, and control the concentration of total volatile solids in the fermentation system at 3%.

[0040] (4) Weigh the water-soluble ferrous salt, add water, and prepare a solution with a ferrous ion concentration of 1000 mg / L.

[0041] (5) Add the ferrous ion solution prepared above into the fermentation bottle in step (3) according to the addition amount of 10 mg per liter.

[0042] (6) Put the fermentation bottle in step (5) in a water bath, ferment at medium temperature (35°C) for 32 days, and collect biogas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com