Glass fiber impregnating agent and application thereof to production of glass fiber yarn for enhancing SMC-A grade surface

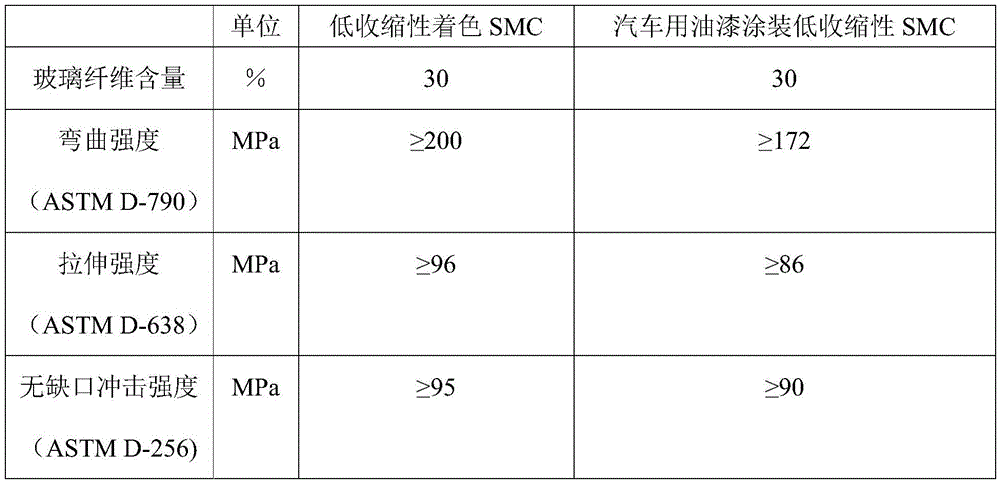

A glass fiber and sizing technology, applied in the field of glass fiber sizing, can solve the problems of high hairiness rate, general mechanical strength of molded products, low operating rate and full drum rate, etc., and achieves less surface marks and no notch impact strength. Good, high start-up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

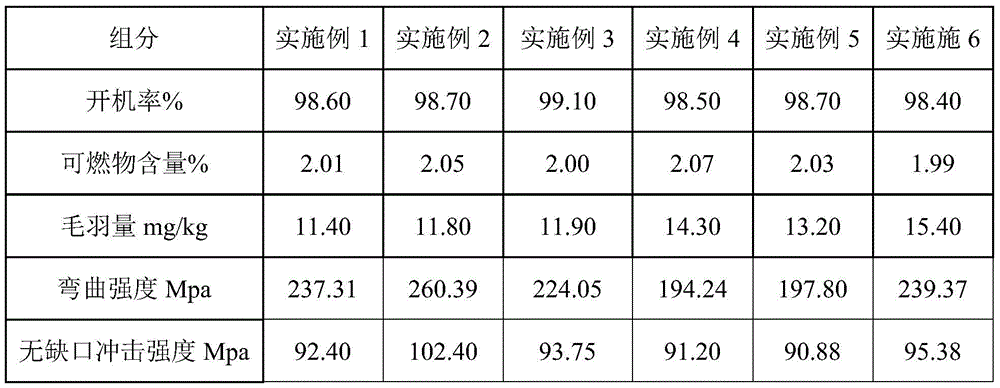

[0053]The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

[0054] In the embodiment of the present invention, the coupling agent 1 is γ-methacryloxypropyltrimethoxysilane, the model is MEMO, and the coupling agent 2 is γ-aminopropyltriethoxysilane, the model is AMEO, purchased from EVONIK; the lubricant was collected from Kekai, the model is JS-808; the polyvinyl acetate emulsion is produced by Franklin, the model is JS-215; the polyester modified epoxy resin emulsion TX-209 is purchased from Jushi Yifen factory; unsaturated polyester emulsion SMC-10 was purchased from the first branch of Jushi Group.

[0055] The specific sizing formulation is shown in Table 1 (where the data in the table is the percentage of the component mass dosage in the total mass of the sizing agent, and if the component is a dispersion system, its mass dosage is based on its solid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com