Magnetic ball chain and preparation method thereof

A ball chain and magnetic technology, applied in the nanometer field, can solve the problems of long reaction cycle, complex multi-steps, high cost, etc., and achieve the effects of controllable size and composition, low preparation cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

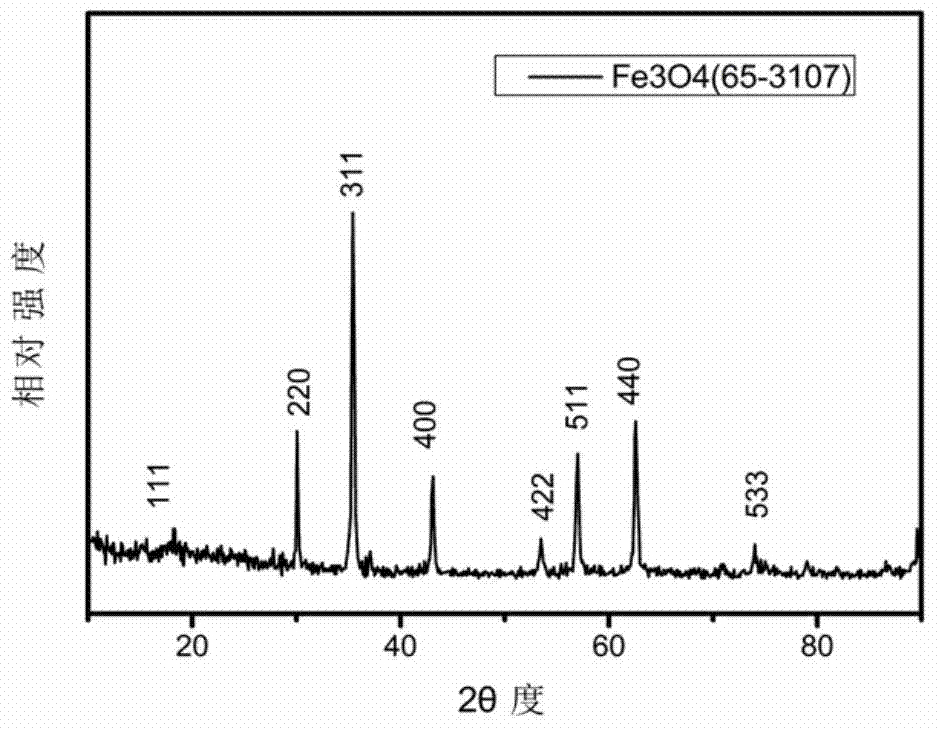

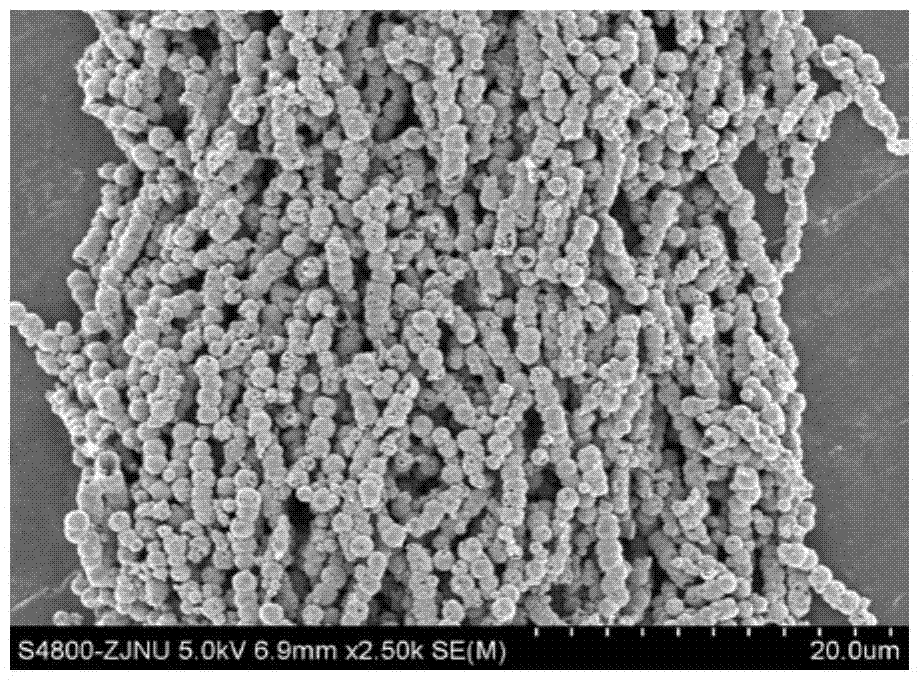

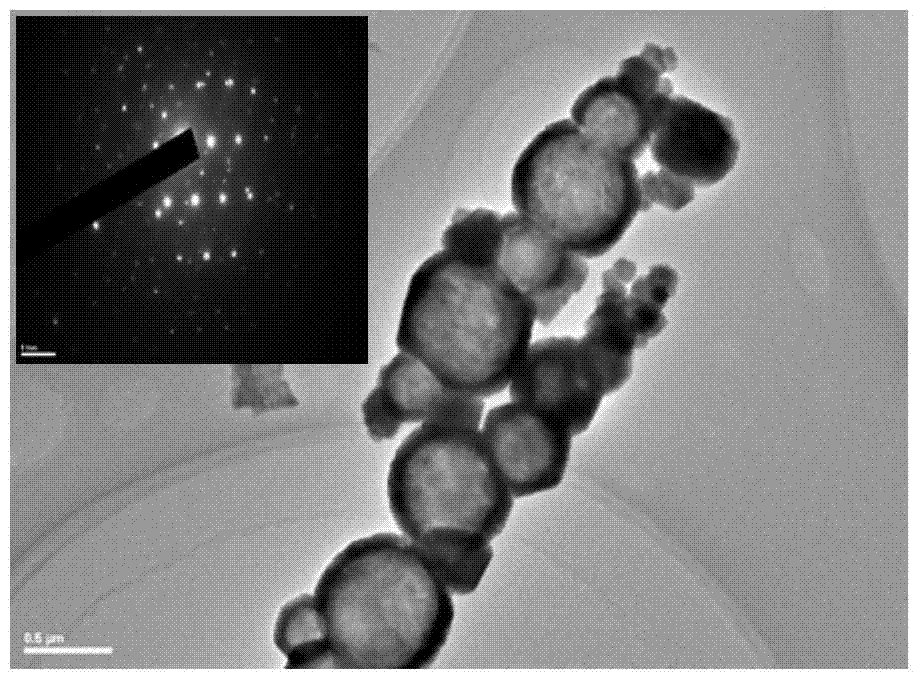

Embodiment 1

[0036] 5mmol FeCl 3 ·6H 2 0, 40mL ethylene glycol, 0.5g polyethylene glycol (that is, the massfraction of surfactant is 0.0125 grams per milliliter) was added in the inner liner of polytetrafluoroethylene, magnetically stirred for 30 minutes; then 10mmol ethylenediamine ( The ratio of the amount of ethylenediamine to the metal salt is 2.0) into the lining and mix and stir for 2.0h; finally put the lining into a stainless steel kettle, and place 2 high-temperature powerful magnets on the bottom or top of the lining, React at 220°C for 12 hours, cool down and wash by centrifugation (first, wash with water and ethanol three times, centrifuge at a speed of 1500 rpm, and centrifuge for 5 minutes), finally separate and wash with water and ethanol by magnetic separation, until the solution is clear, and dry at 60°C 6h to obtain the required hollow magnetic ball chain. The phase of the resulting product, the structure observed under the scanning electron microscope and the morpholog...

Embodiment 2

[0038] Same as Example 1 step, but the reaction time is 6 hours, and the morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 4 As shown, the particle diameter is 1.14-1.37 μm, the chain length is 7.50-11.30 μm, and the aspect ratio is 5.5-9.9.

Embodiment 3

[0040] Same as Example 1 step, but the reaction time is 8 hours, and the morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 5 As shown, the particle diameter is 1.10-1.24 μm, the chain length is 3.65-5.39 μm, and the aspect ratio is 2.9-4.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| polymer chain length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com