Textile conveyor

A technology for textiles and conveyors, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as falling, textile stagnation, easy deviation, etc., to achieve reasonable design, simple structure, and avoid deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] With reference to the drawings, the preferred embodiments of the present invention will be further described in detail.

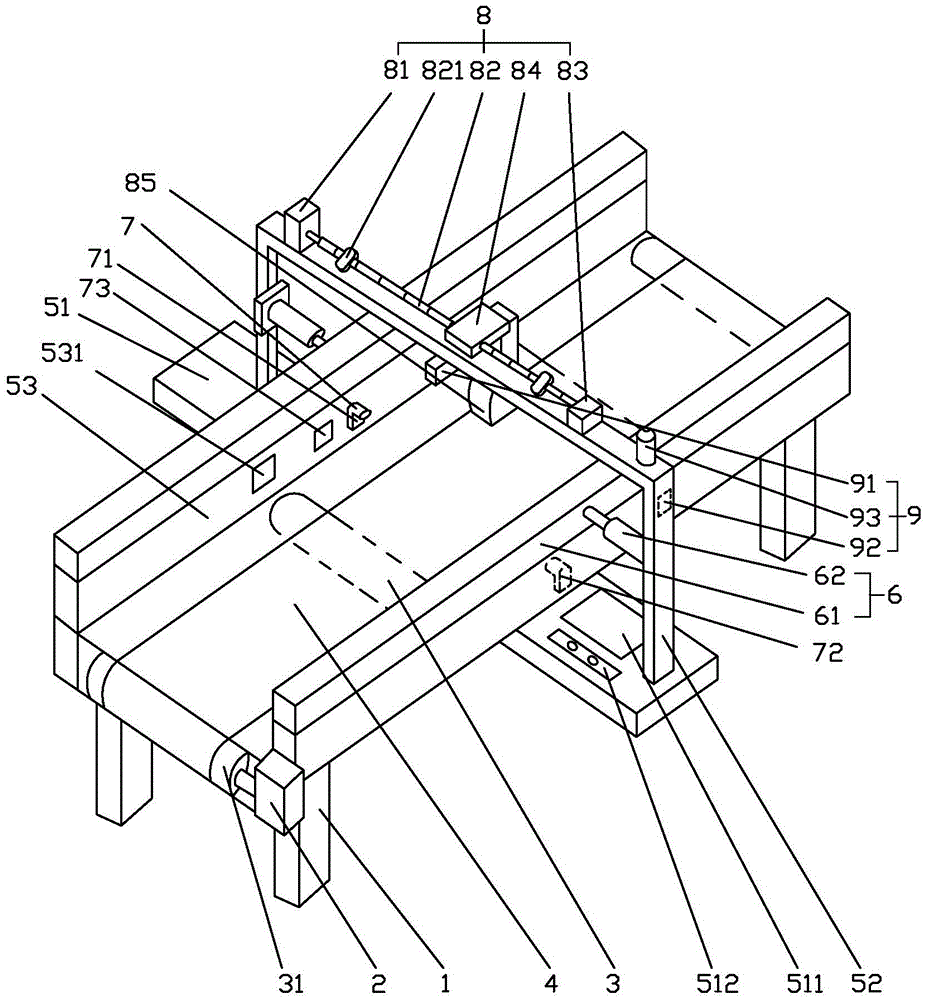

[0014] Such as figure 1 As shown, a textile conveyor includes a frame 1, a driver 2, a roller frame 3, and a conveyor belt 4. The roller frame 3 is located above the frame 1, and the roller frame 3 is composed of at least two rollers 31. Composition, the conveyor belt 4 is wrapped on the roller 31, the roller 31 is connected to the driver 2, the driver 2 adopts a motor, the shaft of the motor is connected to the shaft of the roller 31, and the motor shaft drives the roller 31 to rotate Thereby driving the conveyor belt 4 to circulate rotation, with high degree of automation and convenient maintenance. The left and right sides of the frame 1 are provided with support seats 51, the support seats 51 are provided with gantry brackets 52, and the left and right sides of the conveyor belt 4 are provided with induction plates 53 which are provided with First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com