Online coiling tin prewelding equipment for voice coil motor coil

A voice coil motor and pre-soldering technology, applied in welding equipment, metal processing equipment, welding positions, etc., can solve problems such as poor quality stability, tin bead splashing, and easy deformation of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following describes the present invention through specific embodiments shown in the drawings. However, it should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessary confusion of the concept of the present invention.

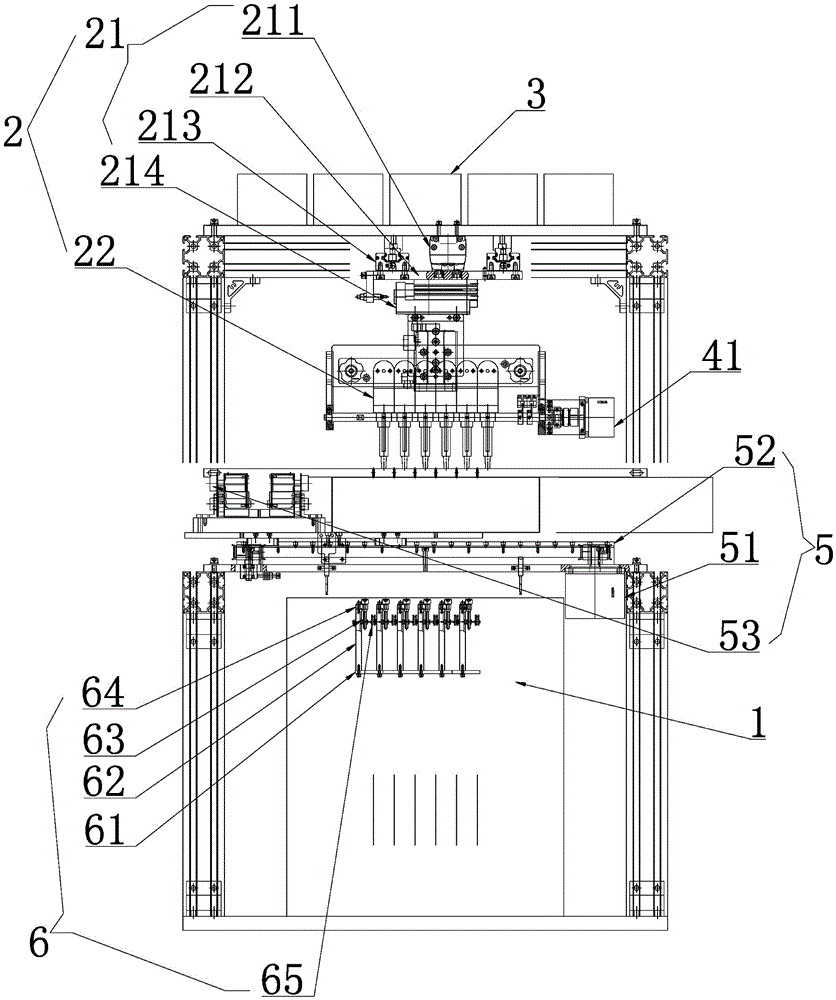

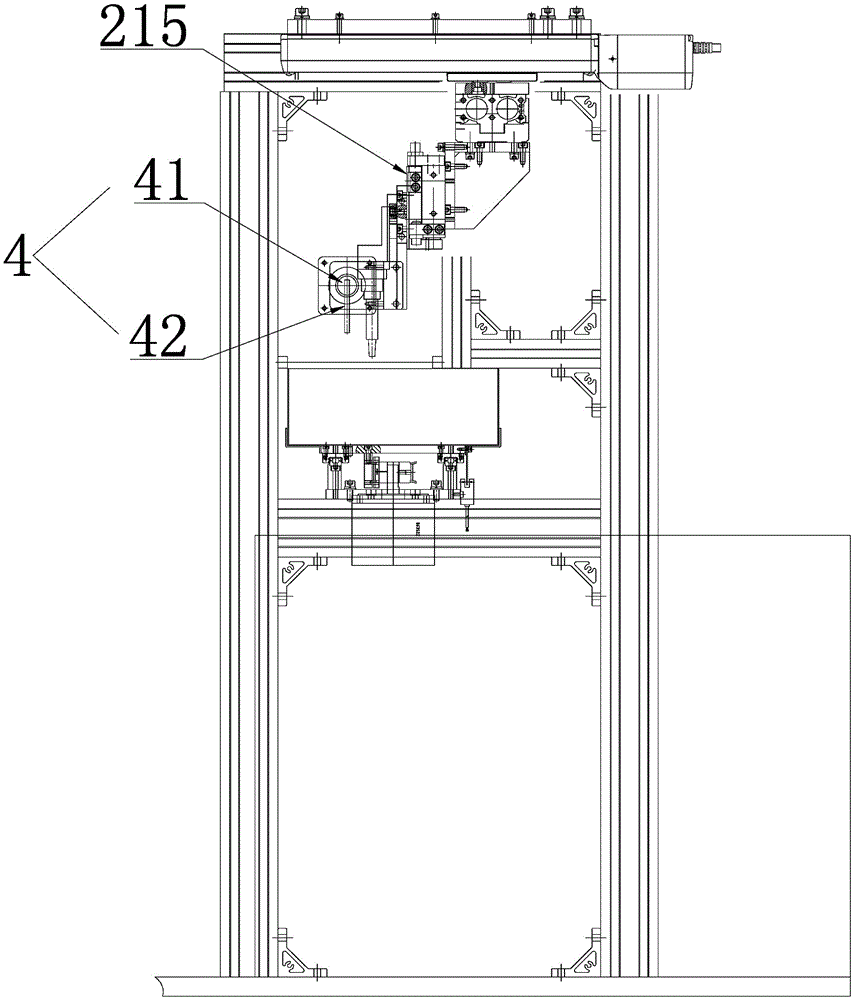

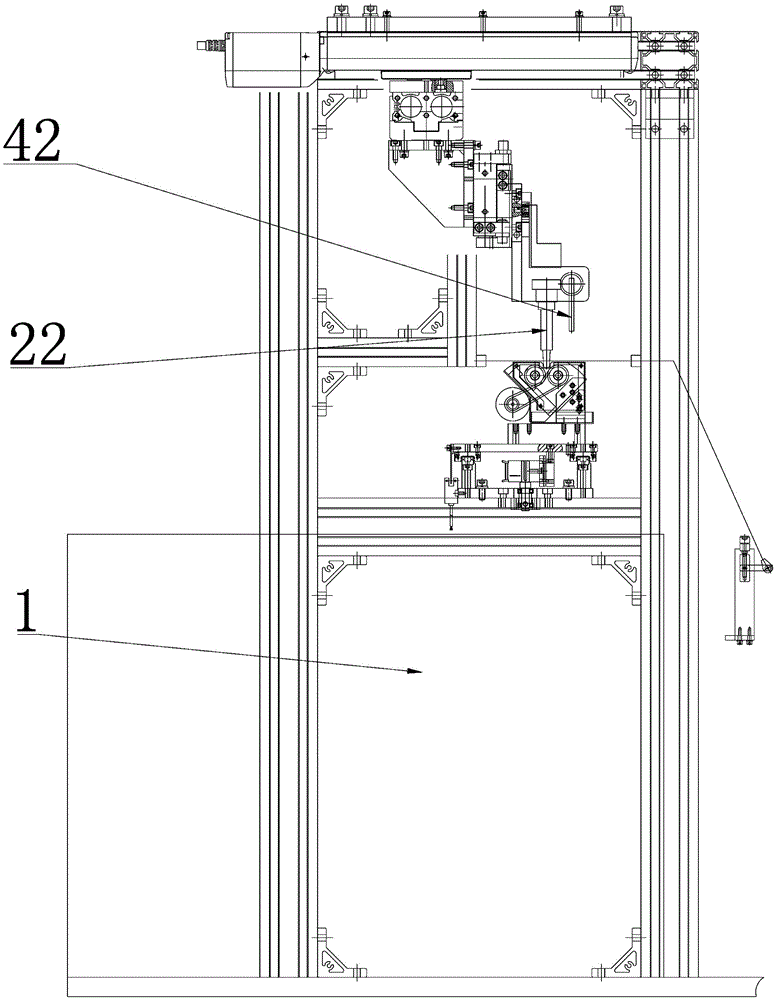

[0025] Refer to Figure 1-3 Shown as an embodiment of the present invention is a voice coil motor coil on-line winding pre-soldering equipment, including a machine 1, which is equipped with an automatic pre-soldering mechanism 2, an automatic tinning mechanism 3, and a tin blowing mechanism 4 that cooperate with each other. And cleaning the soldering iron head mechanism 5; among them, the automatic pre-soldering mechanism 2 includes a pre-soldering tin mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com