Intelligent lump coal dry method inverted separation system

An intelligent, dry technology, applied in sorting and other directions, can solve problems such as difficulty, affecting product quality, jamming chutes, etc., to achieve the effect of maintaining the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

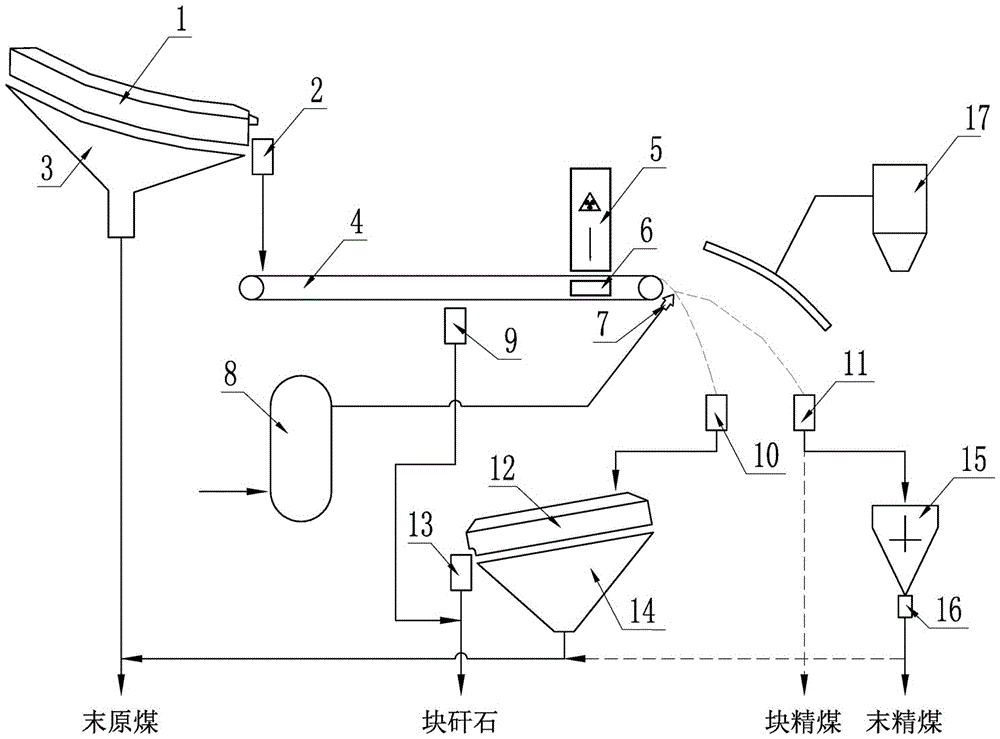

[0029] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0030] Such as figure 1 Shown is a lump coal intelligent dry reverse separation system. After raw coal incoming material is screened by raw coal classification and screening, the lump raw coal enters the intelligent dry separation machine and is divided into clean coal, gangue and sundries by X-ray identification. Its feature is: change the traditional "cracking gangue" of intelligent dry separation into "cracking coal". According to the identification information of X-ray, the intelligent dry separation machine opens the air nozzle controlled by the high-frequency electromagnetic valve corresponding to the position of clean coal, so that the clean coal It deviates from the movement track of raw coal and separates clean coal from gangue and sundries. The intelligent dry separation machine is a dry separation equipment that uses rays to intelligently identify an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com