Mini Jaw Crusher

A jaw crusher, miniature technology, applied in the fields of powder making and ore crushing, can solve the problems of easy damage of bearings, heavy flywheels and pulleys, etc., achieve quick and convenient disassembly, easy repeated and quick assembly and disassembly, and eliminate tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

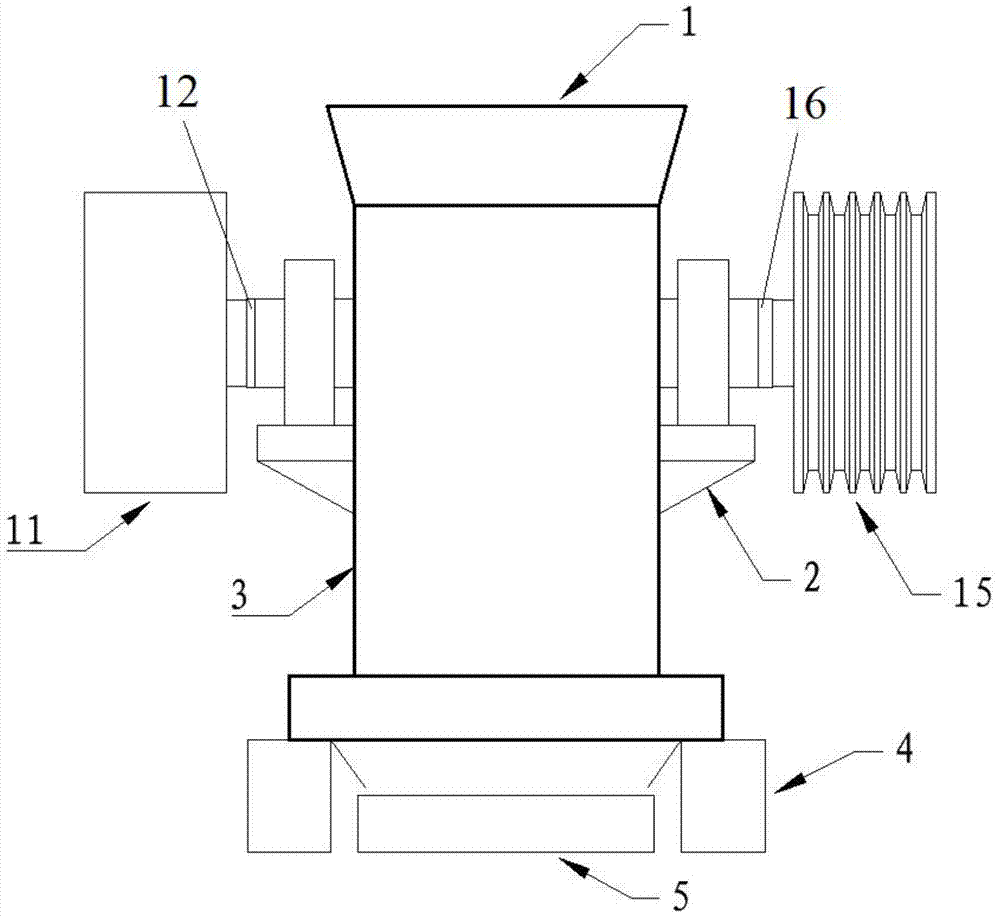

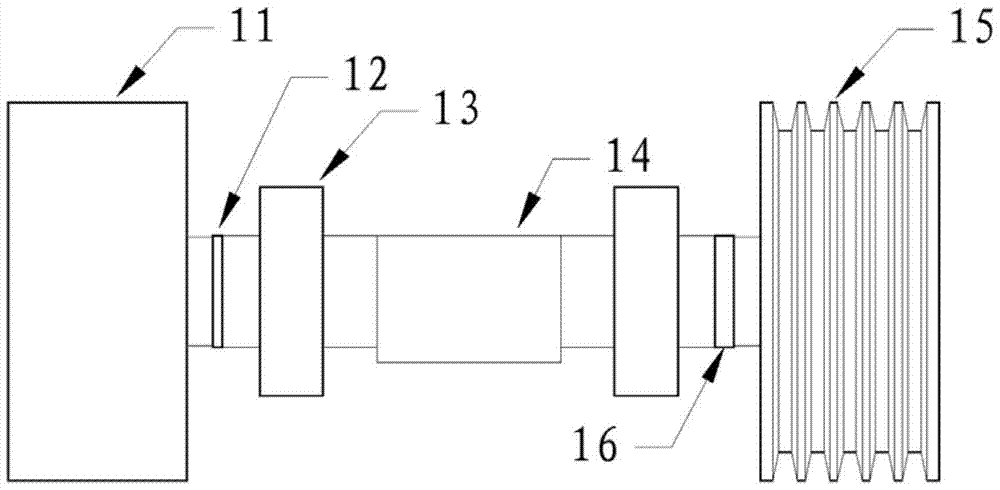

[0028] Such as Figure 1~2 As shown, a miniature jaw crusher includes a feed port 1, a shock absorber 4, a material receiving tray 5, a body 3, and a flywheel 11 and a pulley 15 threadedly assembled with the camshaft 14 of the body 3, respectively.

[0029] The machine body 3 includes a bearing seat 2 , a camshaft 14 , and bearings 13 which are divided into two ends of the camshaft 14 and arranged on the bearing seat 2 .

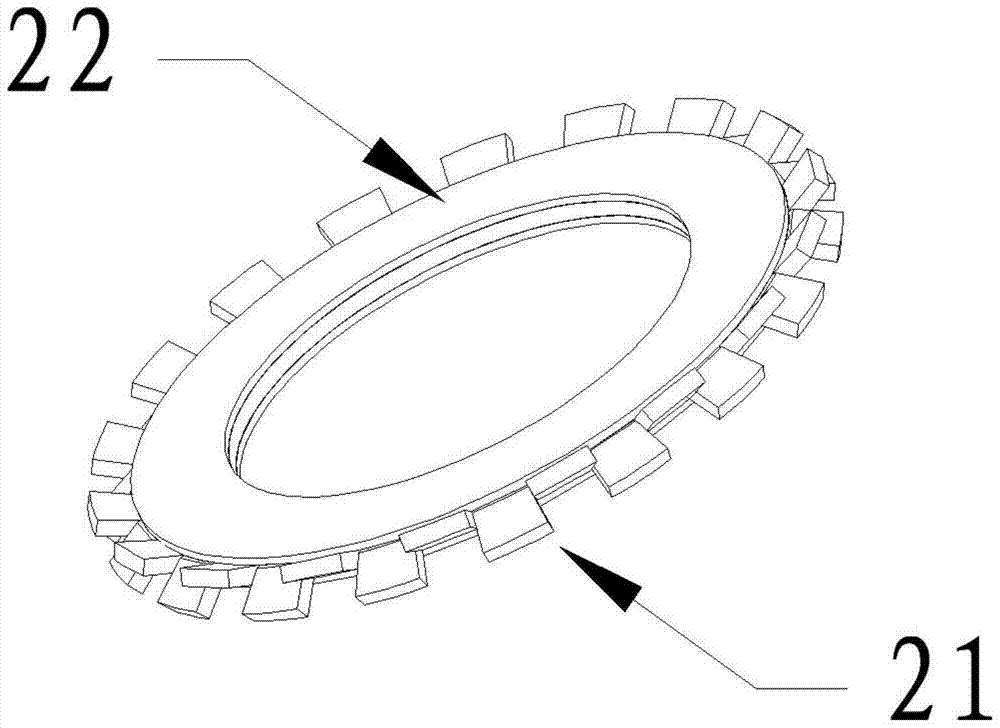

[0030] A copper-plastic composite pad 12 is provided between the flywheel 11 and the camshaft 14 , and a clamp assembly 16 is provided between the pulley 15 and the camshaft 14 . Wherein, the camshaft 14 and the flywheel 11 adopt anti-rotation threads to cooperate, and the belt pulley 15 adopts forward-rotation threads to assemble.

[0031] The use of such positive and negative thread rotation fit can automatically and continuously l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com