Hydrocracking catalyst preparation method

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as environmental pollution, and achieve the effect of reducing acid consumption, reducing emissions, and improving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The ammonium Y-type molecular sieve was subjected to hydrothermal treatment for 3 hours at a temperature of 550°C, a pressure of 0.2MPa, and a water inflow of 200ml / h;

[0028] (2) Wash the molecular sieve obtained in step (1) in a mixed solution of 0.6mol / L nitric acid and 0.2mol / L ammonium nitrate for 2 hours, then add alumina powder and amorphous silica-alumina powder, and then fully roll it Shaped, and then dried at a constant temperature of 100°C for 12 hours. Then calcined at 550°C for 6 hours to obtain a catalyst carrier;

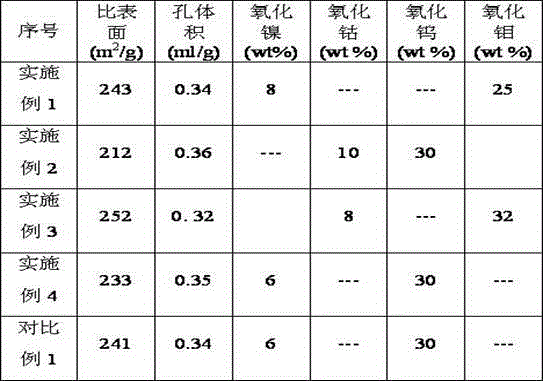

[0029] (3) preparing a metal impregnation solution of W and Ni, impregnating the hydrocracking catalyst carrier obtained in step (2), then filtering, drying at a constant temperature of 100°C for 12 hours, and finally roasting at a constant temperature of 550°C for 6 hours, A hydrocracking catalyst C1 is obtained. Catalyst properties are listed in Table 1.

[0030] The properties of the amorphous silicon-alumina described in step (2) ar...

Embodiment 2

[0032](1) Hydrothermally treat the ammonium Y-type molecular sieve for 1 hour at a temperature of 650°C, a pressure of 0.1MPa, and a water inflow of 200ml / h;

[0033] (2) Wash the molecular sieve obtained in step (1) in a mixed solution of 0.3mol / L nitric acid and 0.8mol / L ammonium nitrate for 1.5 hours, then add alumina powder and amorphous silica-alumina powder, and then fully roll it Shaped, and then dried at a constant temperature of 100°C for 12 hours. Then calcining at 540° C. for 2 hours to obtain a catalyst carrier;

[0034] (3) preparing a metal impregnation solution of W and Ni, impregnating the hydrocracking catalyst support obtained in step (2), then filtering, drying at a constant temperature of 120°C for 6 hours, and finally roasting at a constant temperature of 540°C for 8 hours, A hydrocracking catalyst C4 is obtained. Catalyst properties are listed in Table 1.

[0035] The properties of the amorphous silicon-alumina in step (1) are as follows: the particle ...

Embodiment 3

[0037] (1) The ammonium Y-type molecular sieve is subjected to hydrothermal treatment for 2 hours at a temperature of 600°C, a pressure of 0.1MPa, and a water inflow of 200ml / h;

[0038] (2) Wash the molecular sieve obtained in step (1) in a mixed solution of 0.6 mol / L nitric acid and 0.6 mol / L ammonium nitrate for 1 hour, then add alumina powder, and then fully roll it into shape, and then heat it at 100°C Dry at constant temperature for 12 hours. Then calcining at 550° C. for 4 hours to obtain a catalyst carrier;

[0039] (3) preparing Mo and Co metal impregnation solutions, impregnating the hydrocracking catalyst carrier obtained in step (2), then filtering, drying at a constant temperature of 110°C for 6 hours, and finally roasting at a constant temperature of 480°C for 8 hours, A hydrocracking catalyst C3 is obtained. Catalyst properties are listed in Table 1.

[0040] The specific surface area of the alumina powder described in step (1) is 470m 2 / g, the pore volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com