Silver-silver phosphate-zinc oxide ternary heterogeneous composite structure and preparation method thereof

A composite structure, silver phosphate technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unfavorable materials optoelectronic advantages, unfavorable photo-generated carrier transport, and reduced catalytic activity, etc. Achieve good electron transport properties, superior photocatalytic activity, and broad spectral absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of silver-silver phosphate-zinc oxide ternary heterogeneous composite structure adopts the following steps:

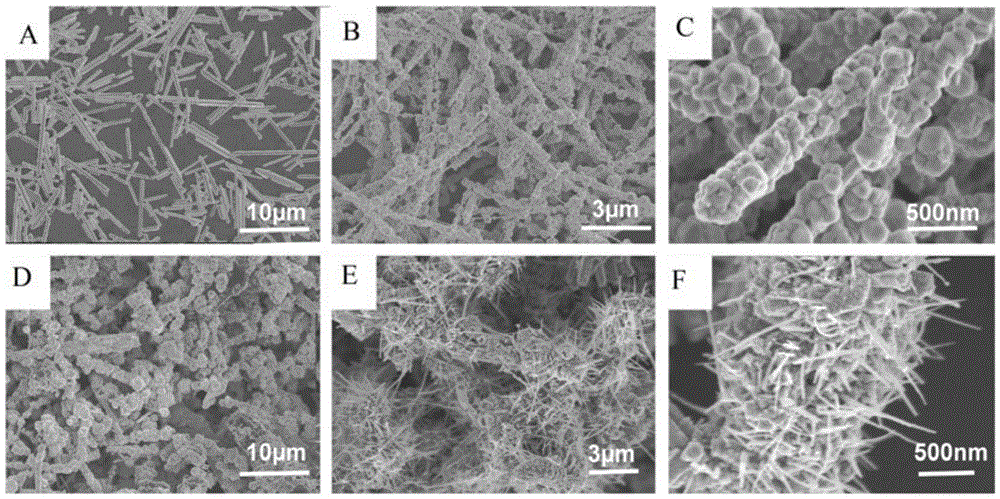

[0021] (1) Take appropriate amount of ethylene glycol (about 6 milliliters) and join in the round bottom flask of 25 milliliters, heat to 160 degrees Celsius, and keep 1 hour at this temperature. Subsequently, 6 milliliters of ethylene glycol solutions of 0.2 mol / L polyvinylpyrrolidone were quickly added, stirred for a while, and 4 mL of silver nitrate (0.15 mol / L) ethylene glycol solutions were added dropwise. The reaction can be carried out for 120 minutes at 160°C. After the product was cooled to room temperature, it was transferred to a 50 ml centrifuge tube, and centrifuged at a speed of 4000 rpm in a centrifuge to remove impurities. Subsequently, they were repeatedly ultrasonically washed and centrifuged with acetone and secondary water for 3-4 times to obtain pure silver nanorods ( figure 1 A). Transfer about 3 milliliters of the...

Embodiment 2

[0023] The preparation method of silver-silver phosphate-zinc oxide ternary heterogeneous composite structure adopts the following steps:

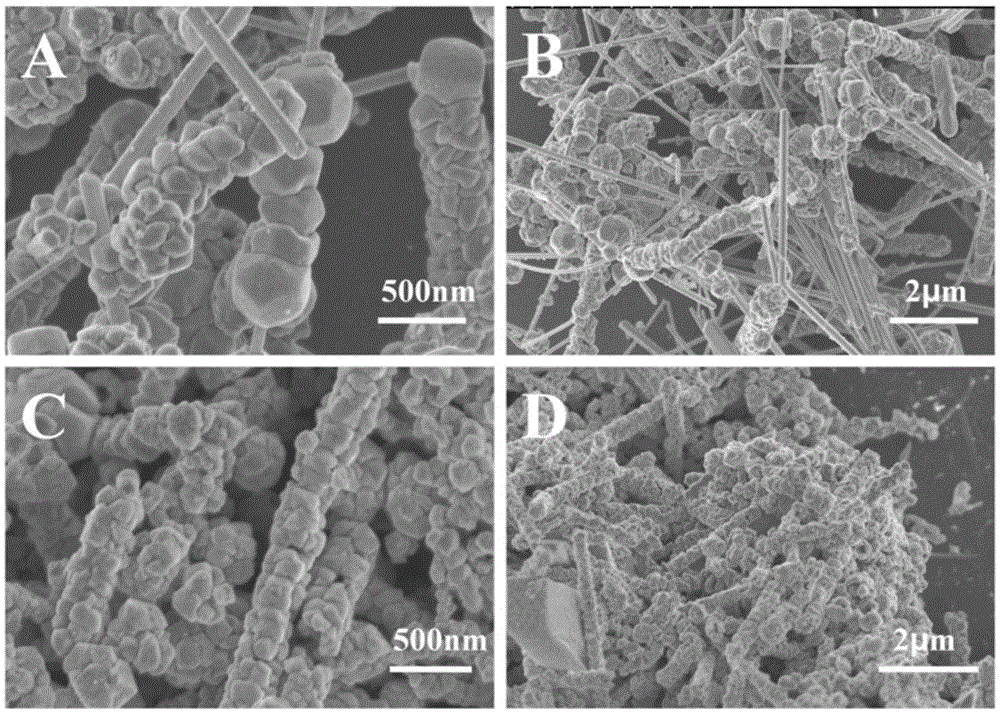

[0024] (1) Take appropriate amount of ethylene glycol (about 6 milliliters) and join in the round bottom flask of 25 milliliters, heat to 160 degrees Celsius, and keep 1 hour at this temperature. Subsequently, 6 milliliters of ethylene glycol solutions of 0.2 mol / L polyvinylpyrrolidone were quickly added, stirred for a while, and 4 mL of silver nitrate (0.15 mol / L) ethylene glycol solutions were added dropwise. The reaction can be carried out for 120 minutes at 160°C. After the product was cooled to room temperature, it was transferred to a 50 ml centrifuge tube, and centrifuged at a speed of 4000 rpm in a centrifuge to remove impurities. Subsequently, the acetone and secondary water were used to repeatedly ultrasonically wash and centrifuge for 3-4 times to obtain pure silver nanorods. Transfer about 3 milliliters of the prepared Ag nan...

Embodiment 3

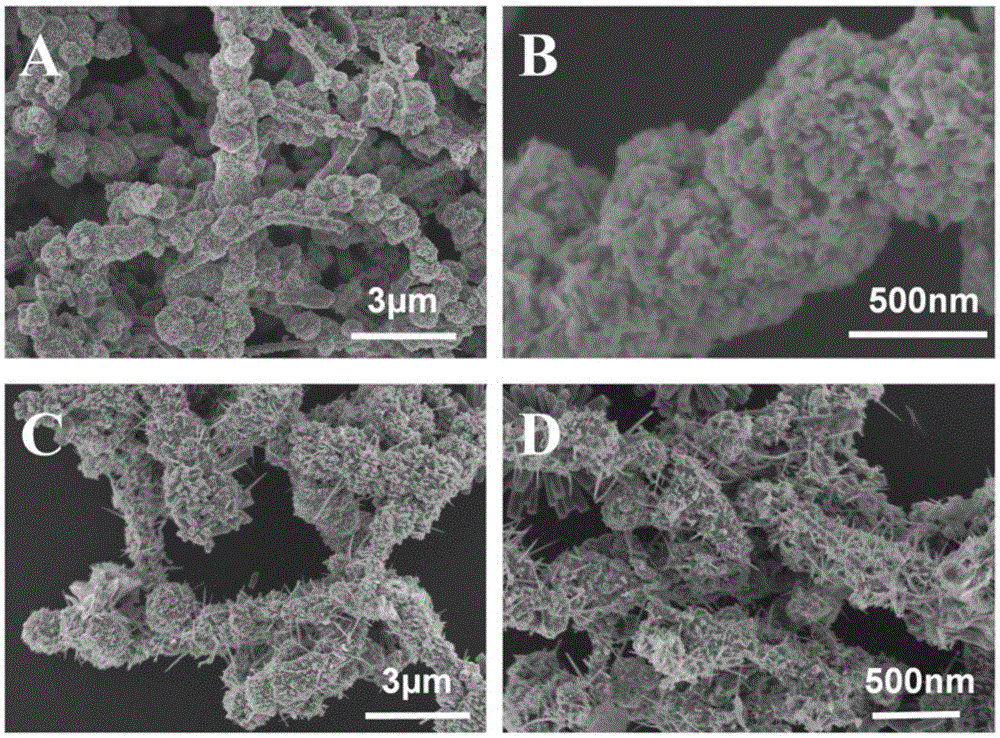

[0026] The preparation method of silver-silver phosphate-zinc oxide ternary heterogeneous composite structure adopts the following steps:

[0027](1) Take appropriate amount of ethylene glycol (about 6 milliliters) and join in the round bottom flask of 25 milliliters, heat to 160 degrees Celsius, and keep 1 hour at this temperature. Subsequently, 6 milliliters of ethylene glycol solutions of 0.2 mol / L polyvinylpyrrolidone were quickly added, stirred for a while, and 4 mL of silver nitrate (0.15 mol / L) ethylene glycol solutions were added dropwise. The reaction can be carried out for 120 minutes at 160°C. After the product was cooled to room temperature, it was transferred to a 50 ml centrifuge tube, and centrifuged at a speed of 4000 rpm in a centrifuge to remove impurities. Subsequently, the acetone and secondary water were used to repeatedly ultrasonically wash and centrifuge for 3-4 times to obtain pure silver nanorods.

[0028] (2) Get about 3 milliliters of the Ag nanor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com