On-off surface active particle utilizing temperature as trigger mechanism

A technology of surface activity and trigger mechanism, applied in dissolution, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex preparation of switchable surfactants, inconvenient application, harsh trigger conditions of switchable surface active particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

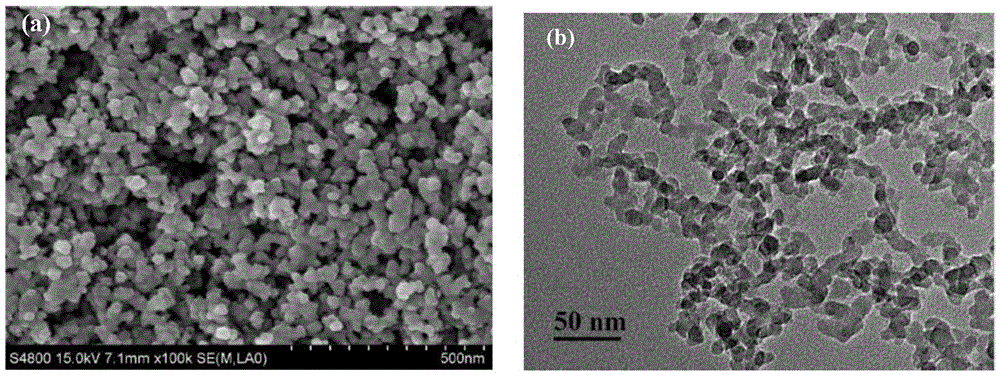

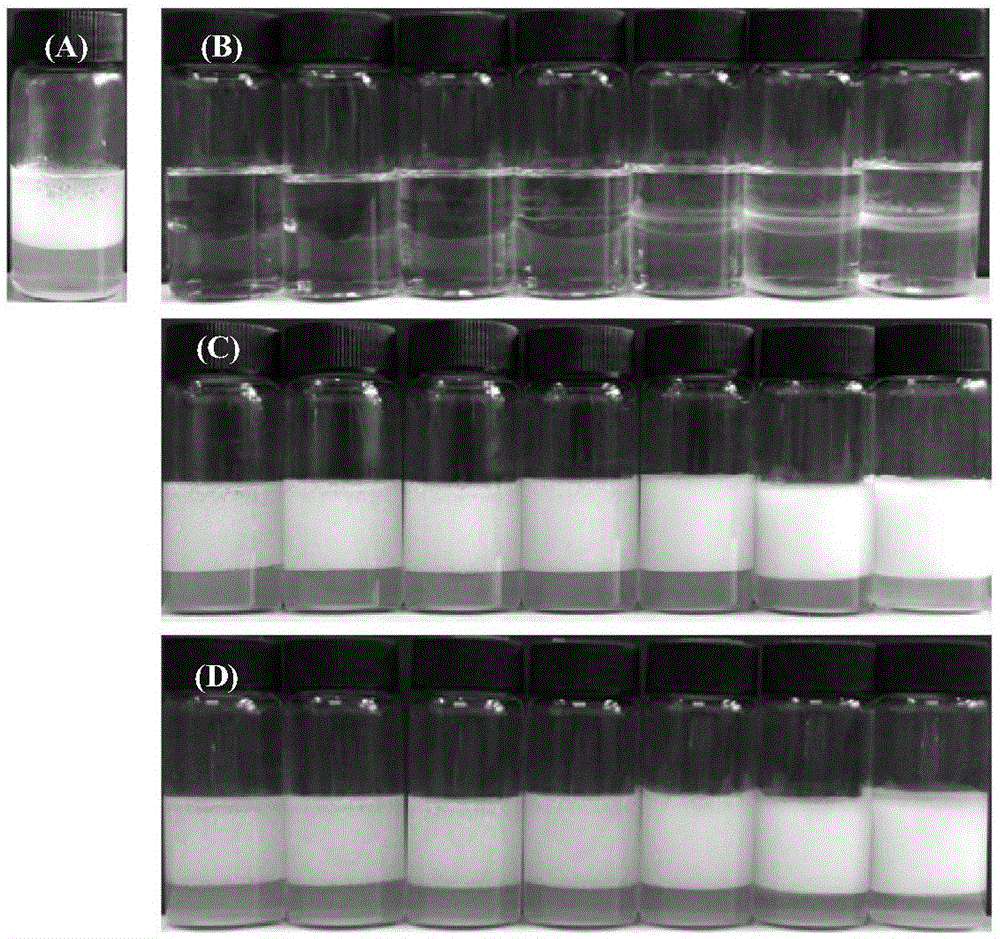

[0022] Example 1: Surface Activity Test of Nano-Silicon Dioxide Particles. Weigh 0.035g commercial nano silicon dioxide particles (HL-220, the primary particle diameter is about 20nm (see figure 1 ), BET specific surface area 200m 2 / g, produced by Wuxi Jinding Longhua Chemical Co., Ltd.), put it into a 25mL vial, add 7mL of pure water, and disperse the particles in water with an ultrasonic disperser (JYD-650, Shanghai) (50W, 1min). The concentration of particles is 0.5% by mass (relative to the aqueous phase). Add 7 mL of toluene (98%, Sinopharm Reagent) to the vial, and emulsify with a high-shear emulsifier (IKA, rotor diameter 1 cm) at 11,000 rpm for 2 min (the same below), but a stable emulsion cannot be obtained, such as figure 2 (A) shown. It shows that the commercial nano-silica particles used do not have surface activity.

Embodiment 2

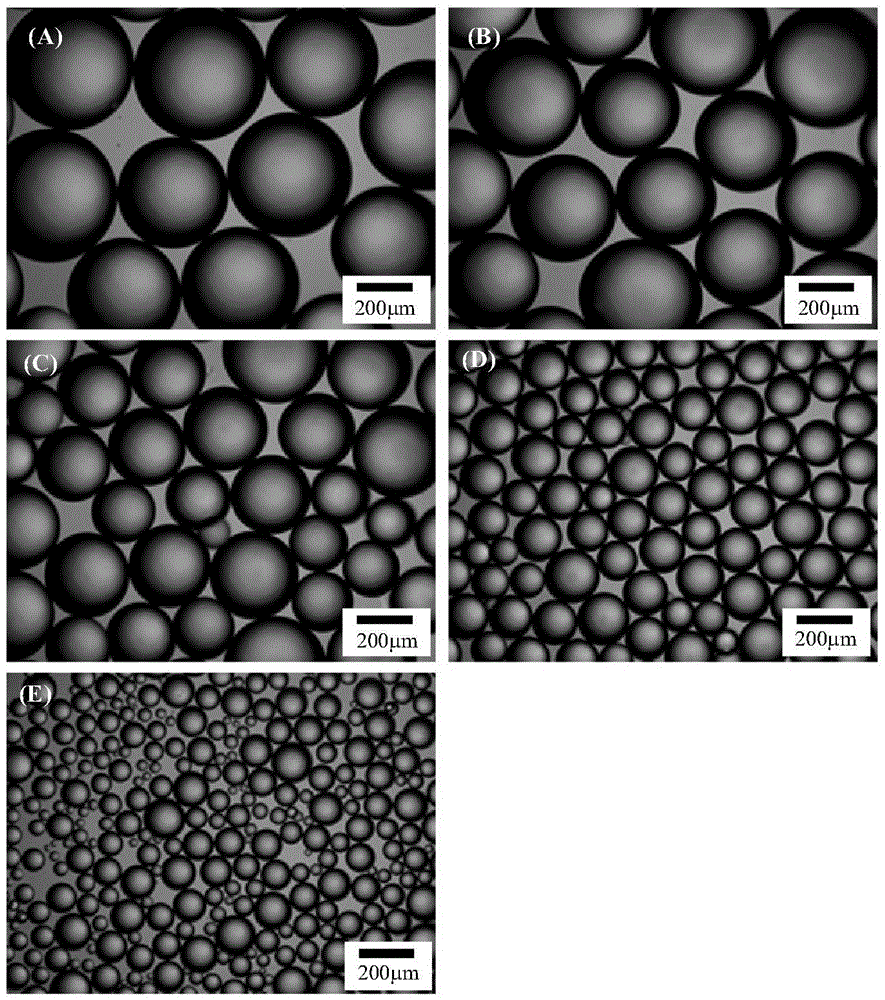

[0023] Example 2: In-situ hydrophobization (surface activation) of nano-silica particles by nonionic surfactants containing short EO chains. With lauryl alcohol polyoxyethylene (5) ether (C 12 E. 5 , each molecule contains 5 polyoxyethylene units, Singma company product) prepare a series of aqueous solutions with different concentrations, take 7mL respectively and put them into 25mL vials, add 7mL toluene, and emulsify with a high-shear emulsifier for 2min, it can be seen that when C 12 E. 5 Concentration at 1.0×10 -5 to 1.0×10 -3 mol / L range (cmc=5.6×10 -5 mol / L), neither can form a stable emulsion, such as figure 2 (B) shown. However, if 0.035g of nano-silica particles are ultrasonically dispersed in the above C 12 E. 5 Add 7 mL of dodecane to the dilute aqueous solution, and emulsify with a high-shear emulsifier for 2 minutes to obtain a stable O / W Pickering emulsion, which has basically no change in appearance after standing for a week, as shown in figure 2 As ...

Embodiment 3

[0024] Example 3: In-situ hydrophobization (surface activation) of nano-silica particles by nonionic surfactants containing short EO chains. Polyoxyethylene lauryl alcohol (3) ether (C 12 E. 3 , each molecule contains 3 polyoxyethylene units, synthesized in the laboratory) Prepare a series of aqueous solutions with different concentrations, take 7mL and put them into 25mL vials, add 7mL toluene, emulsify with a high-shear emulsifier for 2min, it can be seen that when C 12 E. 3 Concentration at 1.0×10 -4 to 6.0×10 -2 mol / L range, can not form a stable emulsion, such as Figure 4 (A) shown. However, if 0.035g of nano-silica particles are ultrasonically dispersed in the above C 12 E. 3 Add 7 mL of dodecane to the dilute aqueous solution, and emulsify with a high-shear emulsifier for 2 minutes, then when C 12 E. 3 Concentration greater than 1.0×10 -3 mol / L, a stable O / W Pickering emulsion can be obtained, which remains stable after being placed for a week, and its appea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com