Acid regeneration acid mist recycling and purifying device

A technology of purification equipment and acid regeneration, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of waste of acid liquid, waste of alkali raw materials, discharge not up to national standards, etc., and achieve smooth operation process, Improved purification efficiency and simple overall configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

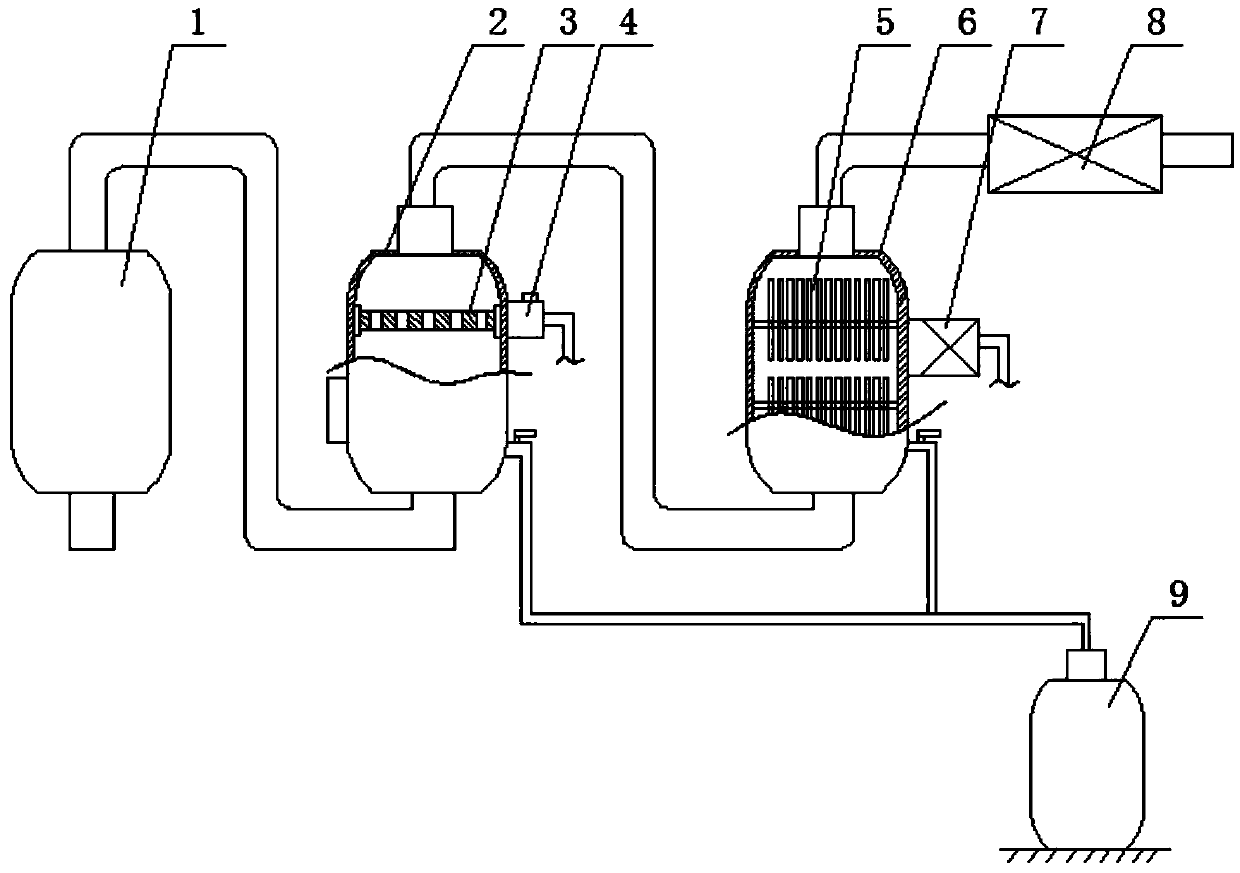

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0015] An acid regeneration acid mist recovery and purification equipment, including a mixing tower 2, a condensation tower 6, an acid recovery tank 9 and an induced draft fan 8, the lower air inlet of the mixing tower is connected to the gas outlet of the roasting furnace, and the upper gas outlet of the mixing tower is connected to the The lower air inlet of the condensing tower and the upper air outlet of the condensing tower are connected to the induced draft fan, which provides the suction force for the operation of the acid liquid in the system. After purification, the qualified air is discharged into the atmosphere.

[0016] The mixing tower is an acid mist water mist mixing tower, and a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com