Inorganic-packaged self-focusing integrated UVLED module

An inorganic and optical technology, applied in the field of ultraviolet lighting, can solve the problems of inability to meet the requirements of the application, the influence of other components, light scattering and other problems, and achieve the effect of increasing the service life, reducing the light-emitting angle, and increasing the light-emitting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

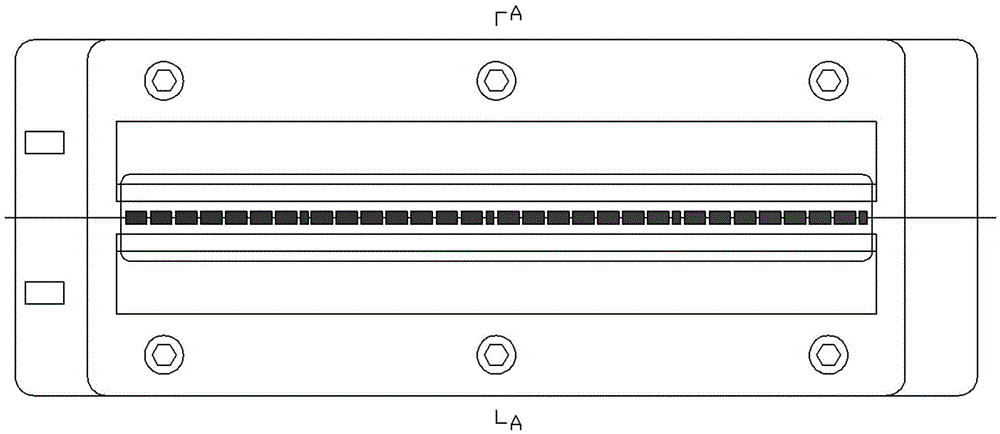

[0032] Such as Figure 1~4 As shown, it shows a specific embodiment of the present invention, an inorganic packaged self-concentrating integrated UVLED module, which is an integrated design, which includes:

[0033] -UVLED lamp body assembly 1; the UVLED lamp body assembly includes a copper-based circuit board 11, the copper-based circuit board 11 is provided with a crystal-bonding area 13, a pad area and surface lines, and the surface of the crystal-bonding area 13 is provided with gold plating layer, the die-bonding area 13, the pad area and the copper-based circuit board are designed in an integrated manner to form the copper-based circuit board 11 together. The heat generated by the operation of the UVLED chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com