Light source, backlight module using same, and liquid crystal display device using same

A technology of backlight module and light source, which is applied in the direction of electric light source, lighting device, light source fixing, etc. It can solve the problems of reducing the light utilization rate of reflected light and light leakage, etc., and achieve the effect of reducing the light-emitting angle and improving the coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

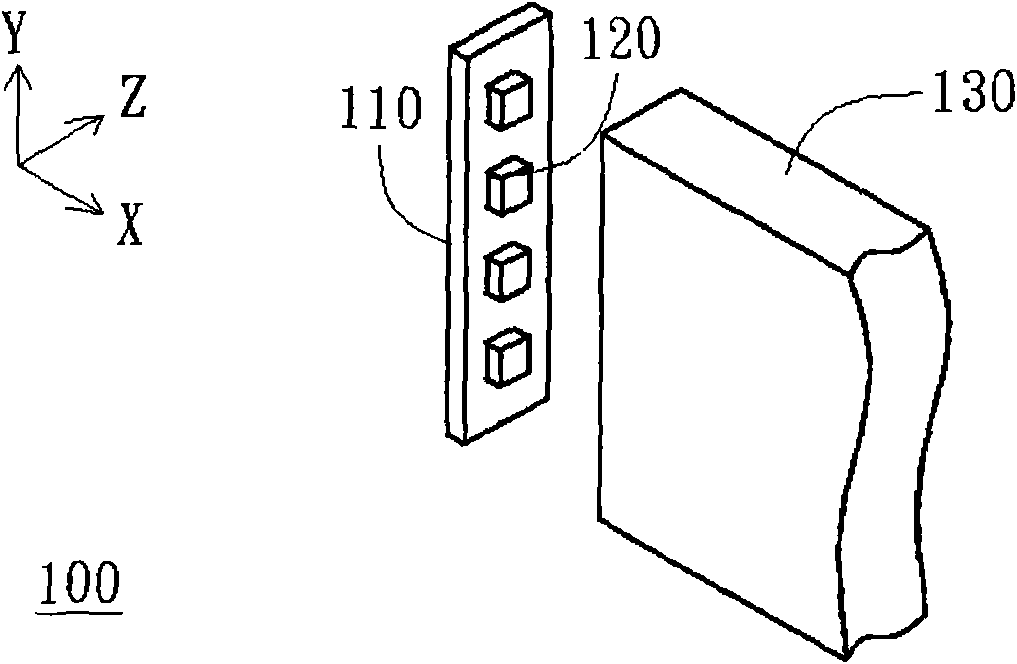

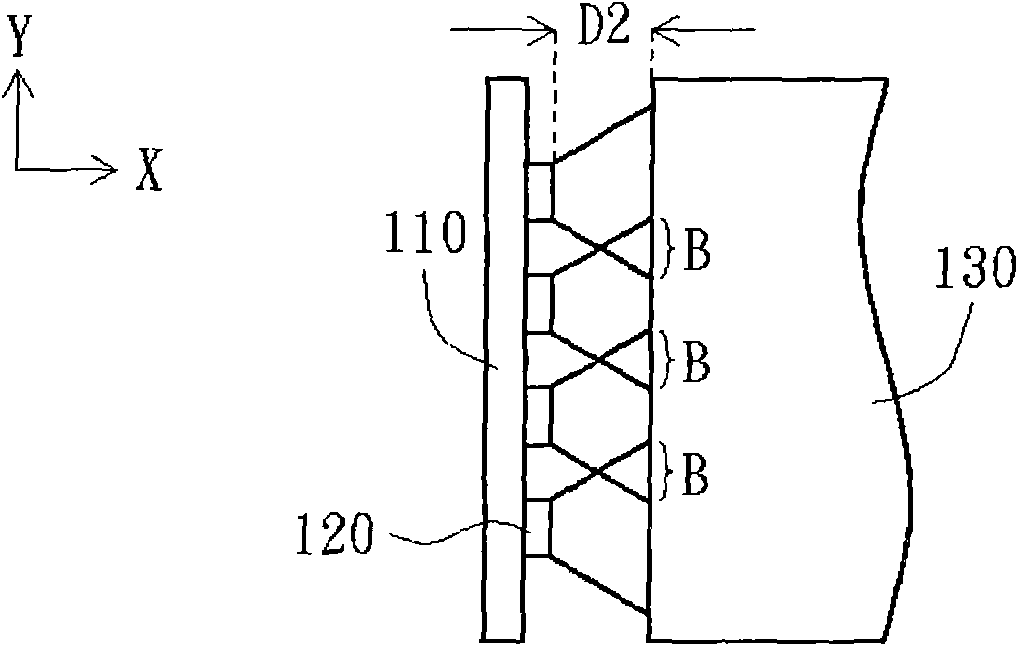

[0051] Please refer to image 3 and Figure 4 , image 3 A schematic diagram showing a liquid crystal display device according to a first embodiment of the present invention, Figure 4 draw image 3 A side view of a liquid crystal display device. The liquid crystal display device 300 includes a liquid crystal display panel 310 and a backlight module 320 . The backlight module 320 is disposed on one side of the liquid crystal display panel 310 and includes a circuit board 330 , at least one LED 340 , at least one lens 350 and a light guide plate 360 . The LED 340 is electrically connected to the circuit board 330 and includes a base 342 , a chip 344 and a package 346 . The chip 344 is disposed on the base 342 and can be, for example, a blue light emitting diode chip (LED chip), but the chip 344 can also be a light emitting diode chip of other colors or other chips capable of emitting light. The lens 350 is disposed on the package body 346 corresponding to the LED 340 , ...

no. 2 example

[0059] The difference between the second embodiment and the first embodiment lies in the bonding method of the lens and the light emitting diode, and other similarities with the first embodiment will not be repeated here. In this embodiment, the lens is fixed on the base of the light emitting diode by the fixing post and the hole. Please refer to Figure 7 , which shows a schematic diagram of a light emitting diode and a lens according to a second embodiment of the present invention. In this embodiment, the lens 450 has fixing columns 451a and 451b, and the fixing columns 451a and 451b extend toward the base 442 and respectively have flanges 452a and 452b. The two ends of the base 442 of the light-emitting diode 440 have holes 441a and 441b respectively. The flanges 452a and 452b are respectively clamped to the base 442 through the holes 441a and 441b to connect the lens 450 to the base 442. The fixing columns 451a and 451b can be connected with the lens. 450 is integrally m...

no. 3 example

[0062] The difference between the third embodiment and the first embodiment lies in the arrangement of the lens. In this embodiment, the lens is fixed on the circuit board, and the rest of the similarities with the above-mentioned first embodiment will not be repeated. Please refer to Figure 8 , which shows a schematic diagram of a light emitting diode, a lens and a circuit board according to a third embodiment of the present invention. In this embodiment, the lens 550 has fixing columns 551a and 551b, and the fixing columns 551a and 551b extend toward the circuit board 530 and have flanges 552a and 552b respectively, and the circuit board 530 has holes 531a and 531b, and the flanges 552a and 552b The circuit board 530 is clamped through the holes 531a and 531b, so as to connect the lens 550 to the circuit board 530. The fixing columns 551a and 551b can be integrally formed with the lens 450 by, for example, transparent resin and injection molding.

[0063] In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com