Method for determining reconfiguration time of reconfigurable manufacturing system

A technology for manufacturing systems and determining methods, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as not considering production conditions, unable to intuitively reflect system changes, and no comprehensive consideration of workpiece and machine tool status.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the drawings and embodiments.

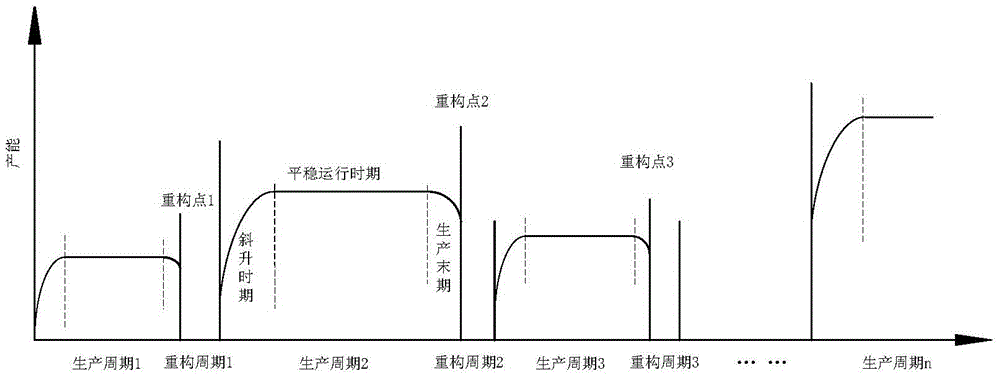

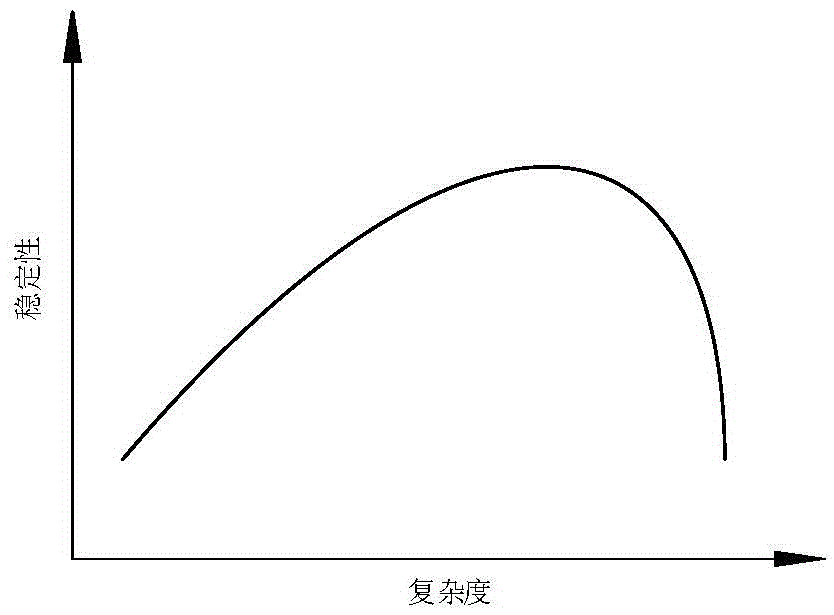

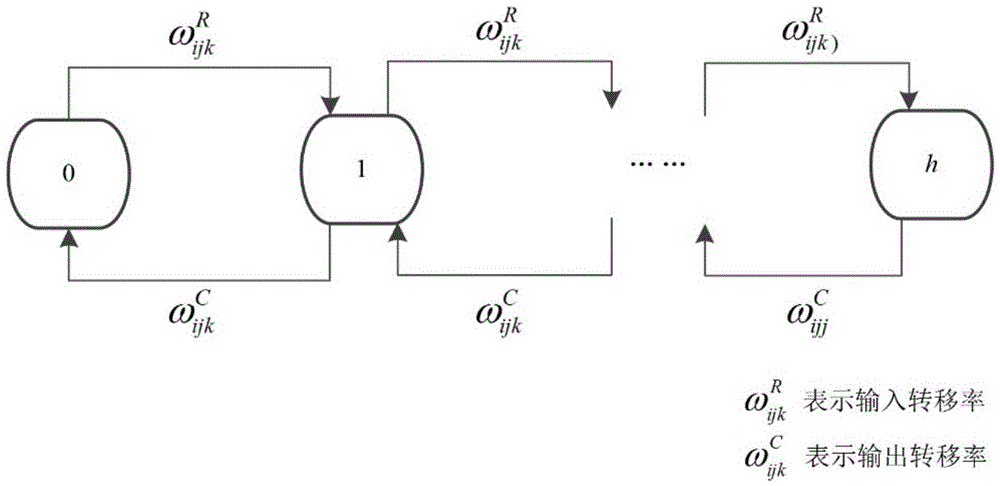

[0038] The present invention provides a method for determining the reconfiguration timing of a reconfigurable manufacturing system. Considering that the RMS system state is determined by the interaction between the workpiece and the machine tool, the workpiece category proposes processing function requirements for the manufacturing system, and the number of workpieces is the manufacturing system The demand for processing capabilities is put forward. As a provider of processing functions and processing capabilities, machine tools have one or more processing functions and a specific number of processing capabilities. Therefore, analyzing the complexity of the manufacturing system from the perspective of processing functions and processing capabilities can well reflect the interaction between the workpiece and the machine tool, and essentially reflect the state of the manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com