An Injector Suitable for Direct Injection of Gas Fuel in Cylinder

A technology of gaseous fuel and in-cylinder direct injection, which is applied to internal combustion piston engines, charging systems, combustion engines, etc., can solve the problems that high pressure cannot be used, refueling cannot be used, and gas cannot be used, so as to reduce requirements and reduce HC The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

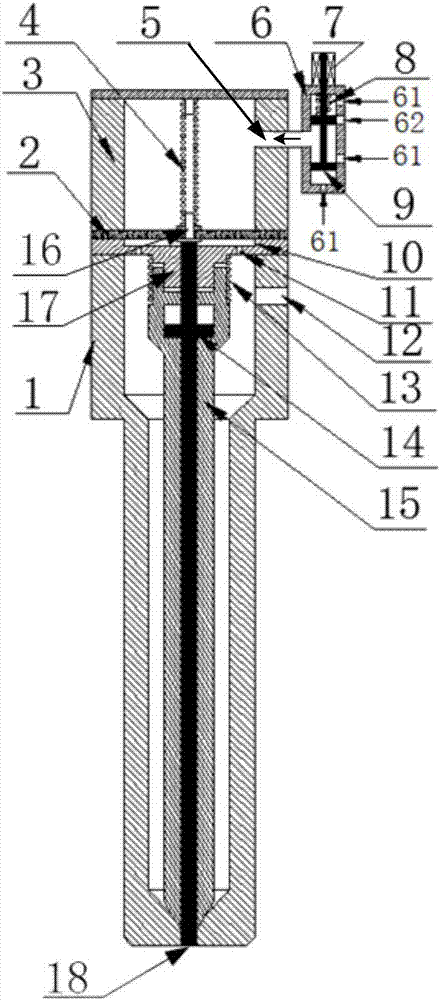

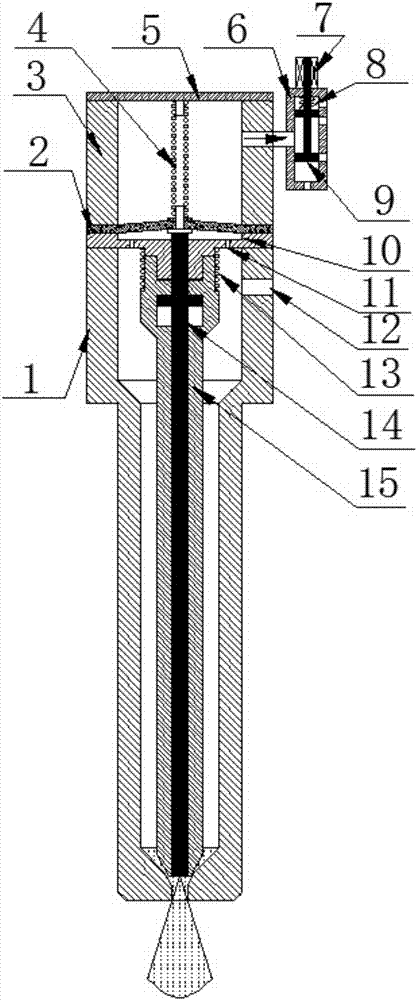

[0020] Such as figure 1 As shown, the injector suitable for in-cylinder direct injection of gaseous fuel described in this embodiment includes three parts: an injection device, an injection control device and an air pressure control device.

[0021] The injection device includes an injector body 1 and a double-needle valve body; the injector body 1 is cylindrical, one end is provided with a gas nozzle 18, the other end is fixedly connected with an injector cover 10, and the side wall is also provided with a gas inlet hole 12; The cover 10 is provided with a ventilation hole 11, and its raised outer edge is fixedly connected with the rubber cushion 2; the double-needle valve body includes an inner needle valve body 14 and an outer needle valve body 15 tightly fitted on the outside thereof, and the inner needle valve body One end of the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com