High-temperature additive for cold rolling of aluminum, and preparation and application thereof

A technology of high-temperature additives and aluminum rolling, applied in the direction of additives, thickeners, petroleum industry, etc., can solve problems such as insufficient lubrication of oil products, achieve the effects of reducing the probability of occurrence, improving high-temperature performance, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

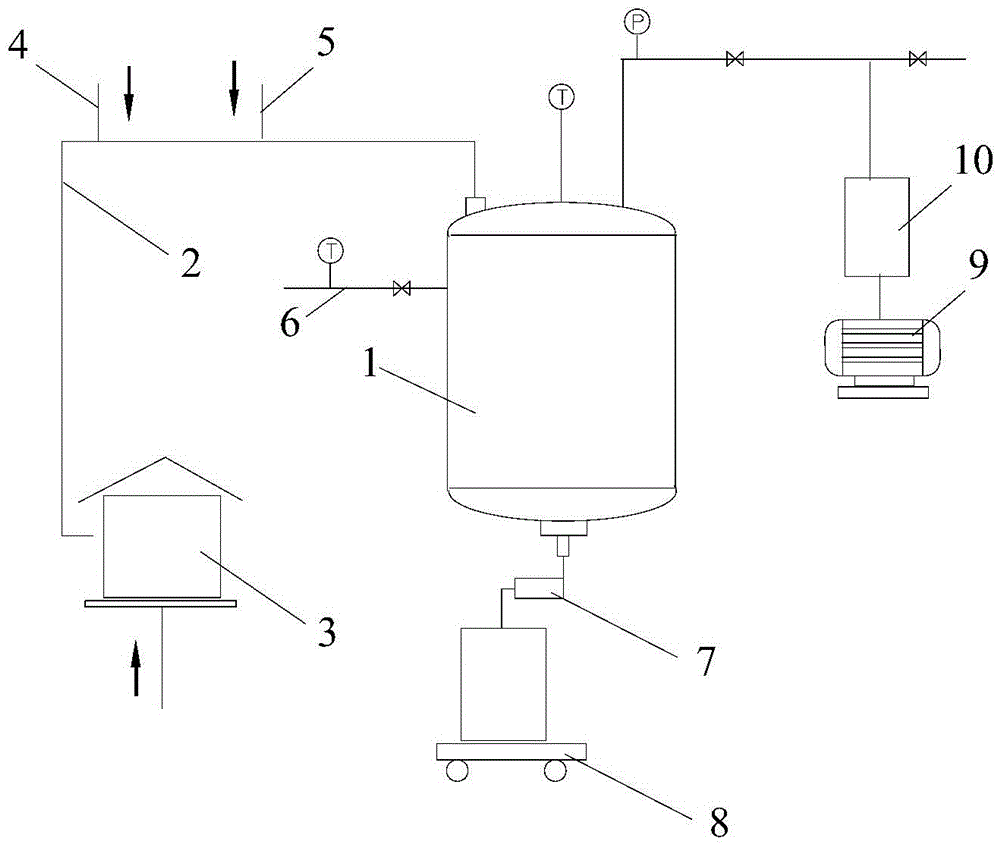

[0044] The present invention is used for preparing the system of high temperature additive for aluminum cold rolling such as figure 1 , including a reaction kettle 1, a feed pipe 2, the feed pipe 2 is connected with a drying room 3, and the drying room is heated with hot water at a temperature of 80°C. The feed pipe 2 is also connected with a base oil feed port 4 and an antioxidant feed port 5 .

[0045] The reaction kettle 1 has a jacket, and the inlet 6 and the outlet of the boiler return water are arranged on the jacket, and the temperature of the boiler return water is 45°C. There is a stirring device in the reaction kettle 1. According to the total mass of reactants, 1000kg is stirred for about 30-50 minutes.

[0046]The side of the reaction kettle away from the raw material inlet is connected to a vacuum pump 9 and a buffer tank 10 through a pipeline, and the vacuum pump 9 is used for vacuum suction. The bottom of the reaction kettle 1 is provided with a discharge filt...

Embodiment 2

[0049] Equipment and preparation steps are with embodiment 1. Aluminum cold rolling high-temperature additive formula: the mass percentages of low molecular weight thickener PB2400, antioxidant (composite antioxidant mixed with T501 and T534, etc.), base oil D90# are 50%, 1%, and 49% respectively .

Embodiment 3

[0054] Equipment and preparation steps are with embodiment 1. Aluminum cold rolling high-temperature additive formula: low molecular weight thickener PB1800, antioxidant is a composite antioxidant mixed with T501 and T534, and base oil D90#, the mass percentages of which are 70%, 3%, and 27% respectively .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com