Desulfurization purification system of coke oven gas

A technology of coke oven gas and purification system, which is applied in the direction of combustible gas purification, combustible gas purification/renovation, and removal of gas pollutants, etc., can solve gas corrosion of gas pipelines and gas-related equipment, reduce steel quality, and low CO content and other problems, to achieve the effect of being suitable for widespread use, avoiding secondary pollution and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

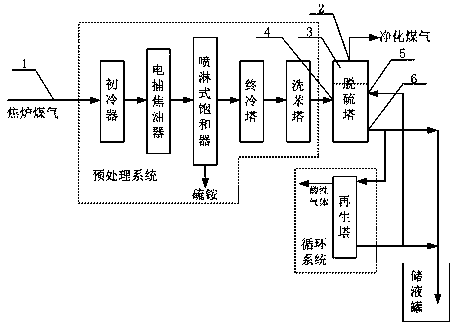

[0025] figure 1 It is the process flow diagram of the coke oven gas desulfurization purification system involved in this embodiment, as figure 1 As shown, it mainly consists of three parts: a pretreatment system, a desulfurization tower and a circulation system. Among them, the pretreatment system includes an initial cooler, an electric tar collector, a spray saturator, and a final cooling Tower and benzene washing tower; the circulation system includes a regeneration tower; the top of the desulfurization tower is provided with a purified gas outlet 2, and the desulfurization tower is connected to the benzene washing tower and the regeneration tower respectively.

[0026] The coke oven gas pipe 1 sends the high-temperature coke oven gas to the primary cooler. After cooling, it is sent to the lower section of the desulfurization tower through the gas inlet 4 after removing tar, ammonia, cooling, and naphthalene. Because the desulfurization liquid inlet 5 of the desulfurization ...

Embodiment 2

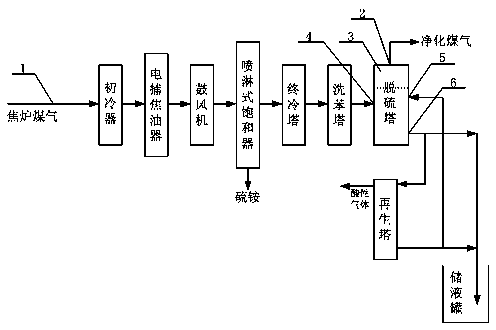

[0029] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, in this embodiment, a blower is connected between the electric tar catcher and the spray saturator, and the gas after tar removal is sent to the spray saturator by the blower for ammonia removal treatment. On the one hand, the blower can reduce the temperature of the gas On the other hand, it can also reduce the water content of the gas, and to a certain extent, can improve the ammonia removal rate of the spray saturator, and the actual use effect is good.

Embodiment 3

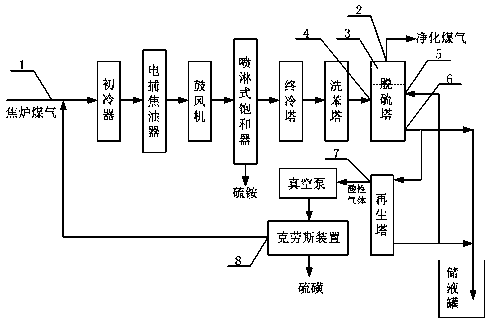

[0031] The difference between this embodiment and embodiment 2 is: as image 3 As shown, the present embodiment is also provided with a Claus device on the basis of embodiment 2, and the regeneration tower regenerates the washing liquid of the desulfurization tower, and the separated acid gas H 2 S, HCN, CO2 The acid gas is sent out from the acid gas outlet 7 on the regeneration tower, and then sent to the Claus device through a vacuum pump, and the tail gas outlet 8 of the Claus device is in communication with the coke oven gas pipe 1. In actual use, the Claus device can remove the elemental sulfur in the acid gas and use it to produce sulfur. After the sulfur is recovered, it can be used in medicine, chemical industry and other fields. The gas tail gas after the elemental sulfur is removed is sent to the coke oven through the tail gas outlet 8 The gas pipe, on the one hand, can reduce the temperature of coke oven gas, and on the other hand, can purify the tail gas here, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com