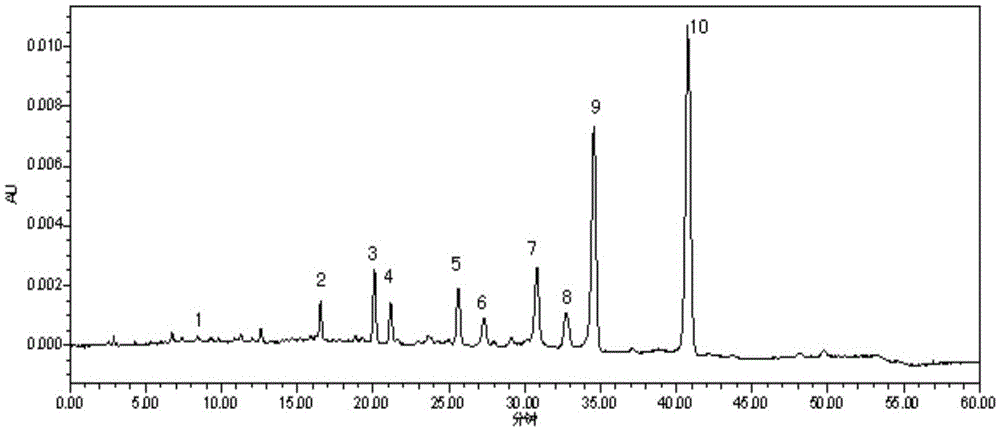

Process method for separating and purifying bitespiramycin

A technology of bitspiramycin and process method, which is applied in the field of separation and purification of antibiotics, can solve the problems of many types of components and impurities, instability of fermentation broth, etc., achieve orderly crystal forms, clear control indicators, and eliminate local excessive The hidden effect of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

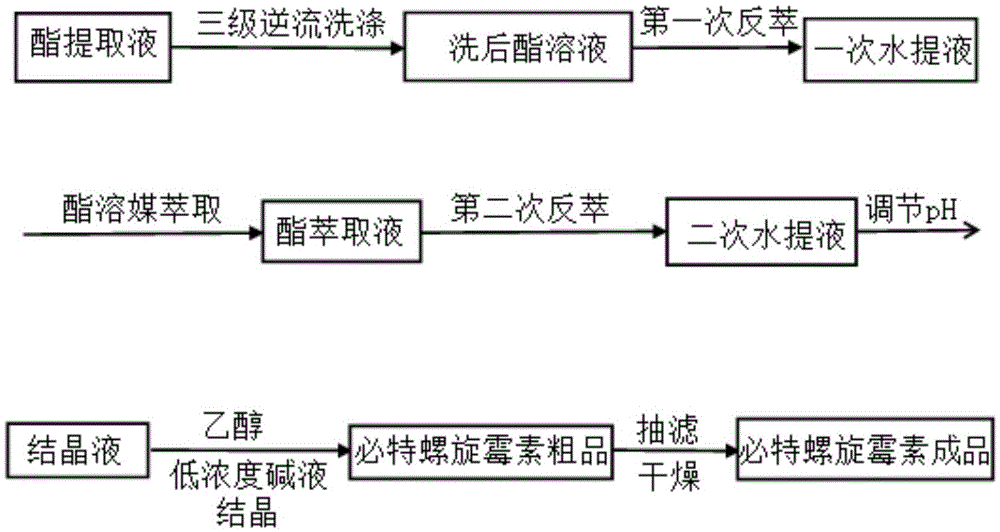

Method used

Image

Examples

Embodiment 1

[0049] (1) Three-stage countercurrent washing: the butyl acetate extract containing the titrepiromycin titer of 7234u / ml was washed with 0.8% NaH 2 PO 4 The solution was washed countercurrently by a three-stage centrifuge. The washing temperature was 20° C., and the washing phase was water phase: ester phase = 1:1.5, so that the after-washing solution of bitspiramycin with an ester phase titer of 5593u / ml was obtained.

[0050] (2) Buffer back extraction: the separated butyl acetate washing liquid is 0.7% NaH with pH=2.2, mass fraction 2 PO 4 Solution stripping, the stripping phase is the water phase: ester phase = 1:4.5, the water and ester are mixed and stirred, and the water phase is mixed with H 3 PO 4 Adjust the pH of the water phase to 3.60, let stand to separate the liquids, and obtain the back-extraction solution of Bitespiramycin with a titer of 21708u / ml in the water phase.

[0051] (3) Butyl acetate extraction: adjust the pH of the aqueous phase phase extract o...

Embodiment 2

[0056] (1) Three-stage countercurrent washing: the butyl acetate extract containing the titrepiromycin titer of 9078u / ml was washed with 1% NaH 2 PO 4 The solution was washed countercurrently by a three-stage centrifuge. The washing temperature was 20° C., and the washing phase was water phase: ester phase = 1:1.5, so that the after-washing solution of bitspiramycin with the titer of the ester phase was 5249u / ml was obtained.

[0057] (2) Buffer stripping: the separated butyl acetate washing liquid is washed with 0.7% NaH of pH=2.2 2 PO 4 Solution stripping, the stripping phase is the water phase: ester phase = 1:4, the water and ester are mixed and stirred, and the water phase is mixed with H 3 PO 4 Adjust the pH of the water phase to 3.85, let stand to separate the liquids, and obtain the back-extraction solution of Bitespiramycin with a titer of 20468u / ml in the water phase.

[0058] (3) Butyl acetate extraction: adjust the pH of the aqueous phase extract of bispirulin...

Embodiment 3

[0063] (1) Three-stage countercurrent washing: the butyl acetate extract containing the titrepiromycin titer of 8578u / ml was washed with 0.9% NaH 2 PO 4 The solution was washed countercurrently by a three-stage centrifuge. The washing temperature was 20° C., and the washing phase was water phase: ester phase = 1:1.5, so that the after-washing solution of bitspiramycin with an ester phase titer of 6091u / ml was obtained.

[0064] (2) Buffer stripping: the separated butyl acetate washing liquid is washed with 0.7% NaH of pH=2.2 2 PO 4 Solution stripping, the stripping phase is the water phase: ester phase = 1:3.5, the water and ester are mixed and stirred, and the water phase is mixed with H 3 PO 4 Adjust the pH of the water phase to 3.75, let stand to separate the liquids, and obtain the back-extraction solution of Bitespiramycin with a titer of 20972u / ml in the water phase.

[0065] (3) Butyl acetate extraction: adjust the pH of the aqueous phase phase extract of Bitespira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com