A multi-stage enhanced catalytic redox aeration internal electrolysis reactor and its application

A technology of catalytic oxidation and internal electrolysis, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve low treatment efficiency, dead angle, increased equipment operating costs, etc. problems, to achieve the effect of large reaction participation surface area, convenient replacement, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

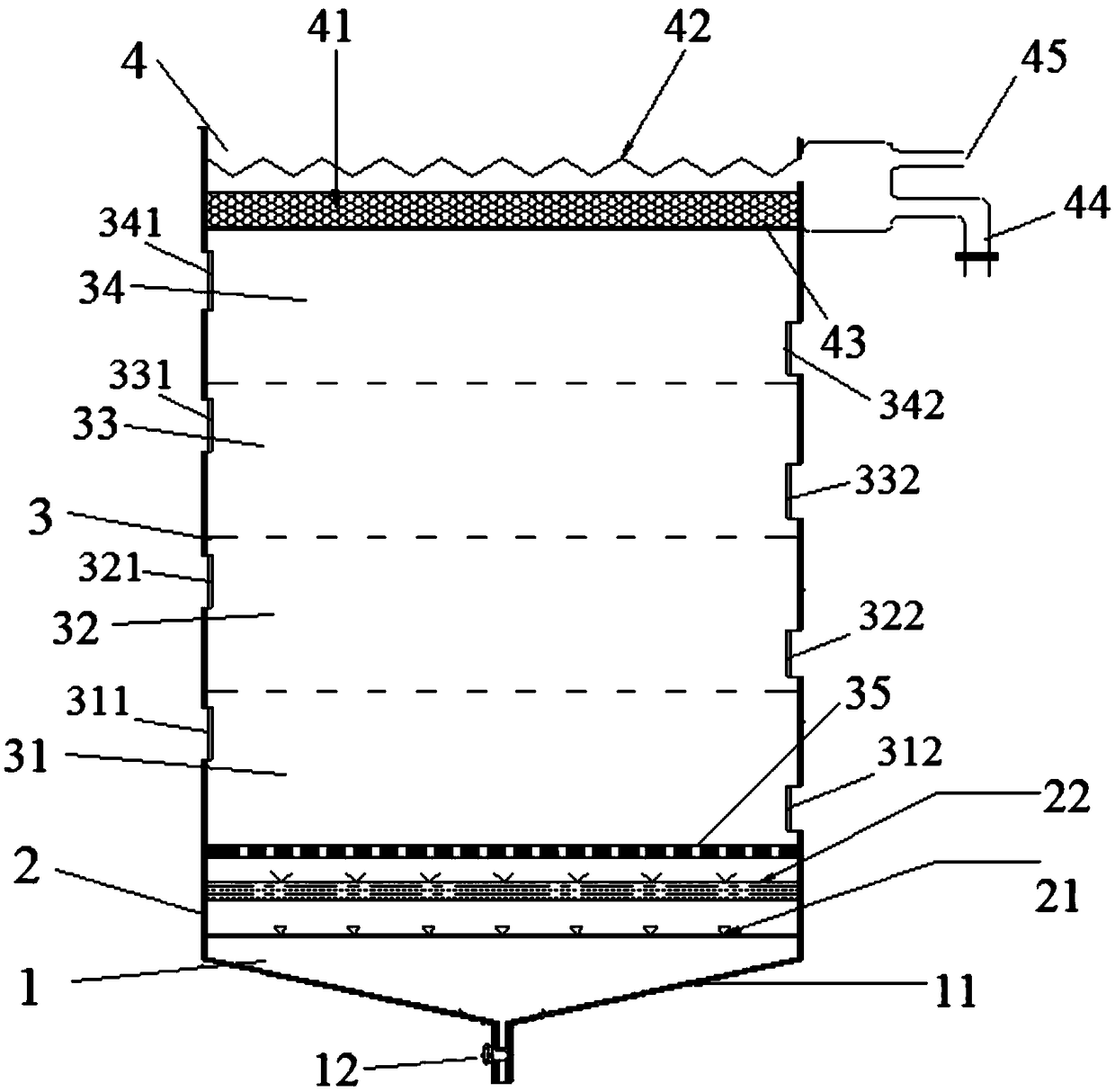

[0046] A multi-stage enhanced catalytic redox aeration internal electrolysis reactor, its structure is as follows figure 1 As shown, for the treatment of wastewater, the reactor is provided with a sedimentation layer 1, a water inlet air distribution layer 2, a multi-stage packing layer 3 and a water outlet layer 4 in sequence from bottom to top.

[0047] The sediment layer 1 is provided with a funnel-shaped sludge collection assembly 11 at the bottom, and the sewage outlet of the sludge collection assembly 11 is provided with a sewage discharge screw 12 for controlling the switch, and the included angle of the section of the sludge collection assembly 11 is 155° .

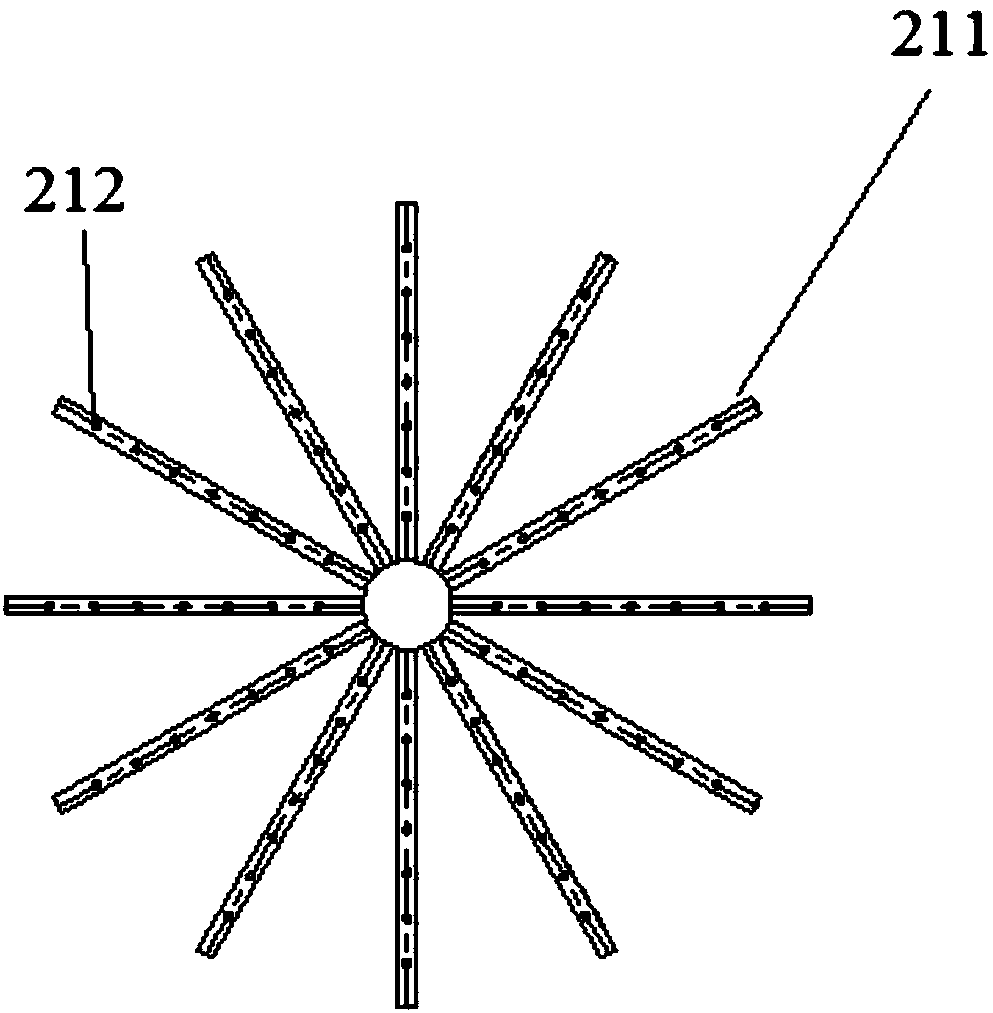

[0048] The water inlet air distribution layer 2 includes an air distribution assembly 21 and a water inlet assembly 22 arranged on the air distribution assembly 21. The air distribution assembly 21 is formed by 12 air distribution pipes 211 connected to the external air intake parts and arranged at intervals towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com