Graphene compound conductive powder and preparation method thereof

A graphene composite, conductive powder technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve problems such as easy agglomeration, reduced dispersion, and unfavorable downstream product applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

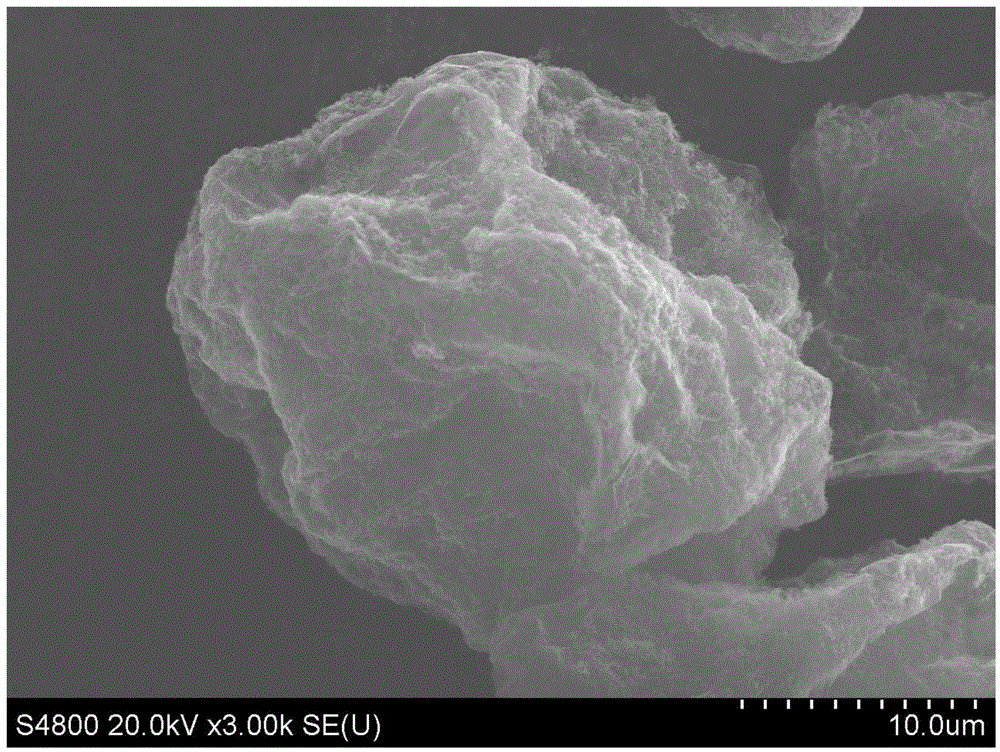

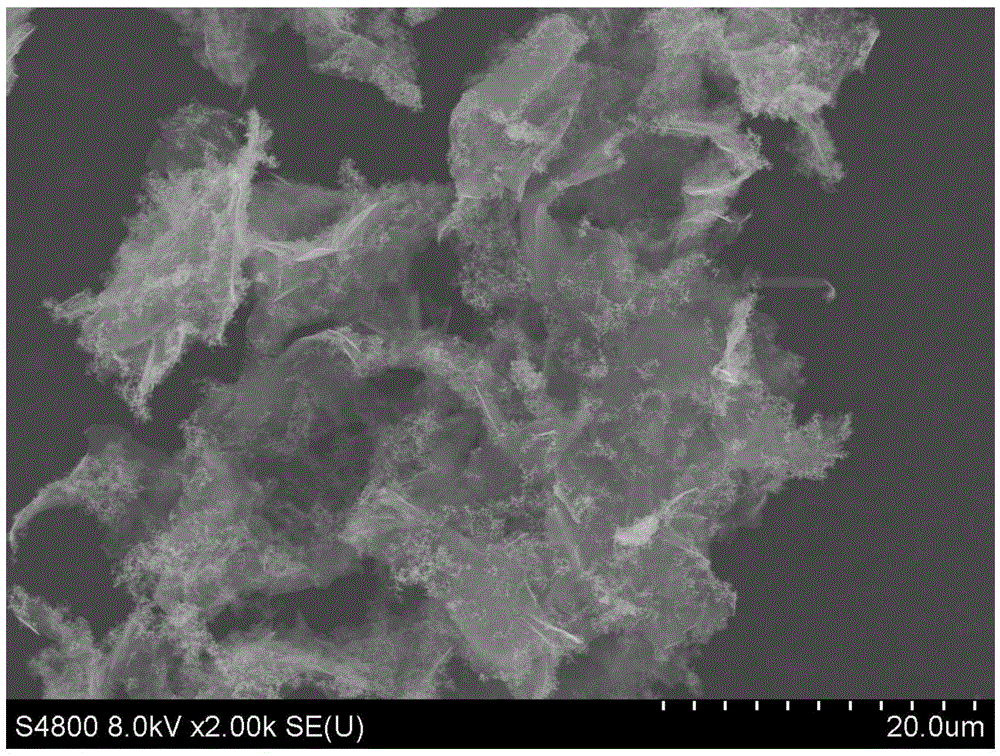

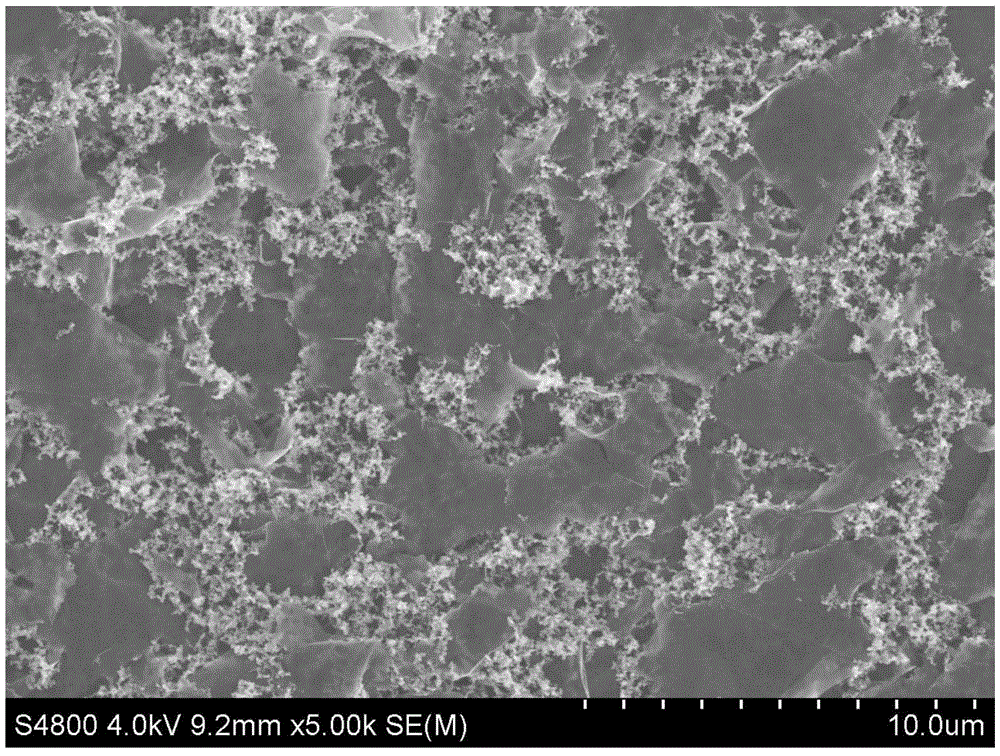

Image

Examples

preparation example Construction

[0033] The application also provides a preparation method of graphene composite conductive powder, comprising the following steps:

[0034] Mixing graphene material, polypyridine compound and water to obtain graphene water-based slurry;

[0035] Mixing the conductive carbon material, the carboxyl-containing compound and water to obtain a conductive carbon water-based slurry, the conductive carbon material does not include graphene;

[0036] Mixing the graphene water-based slurry with the conductive carbon water-based slurry, hydrogen bond self-assembly to obtain a self-assembled intermediate slurry;

[0037] The self-assembly intermediate slurry is dried to obtain a graphene composite conductive powder.

[0038] In the process of preparing the graphene composite conductive powder, the applicant first prepares the graphene aqueous slurry. The present application is not limited to the source and preparation method of the graphene, and the graphene products well-known to those ...

Embodiment 1

[0055] The graphene water-based slurry that mass concentration is 2% and the conductive carbon water-based slurry that mass concentration is 4% are prepared respectively:

[0056] a) preparation of graphene material water-based slurry with a mass concentration of 2%: take 40Kg of a graphene water-based slurry with a mass concentration of 5%, and weigh it according to the mass ratio of graphene material and polypyridine compound material at 1:0.1 0.2Kg of 4'-(4-methylphenyl)-2,2:6',2"-terpyridine was added to the above graphene aqueous slurry, diluted with water until the graphene content was 2%, and the above mixed The material is stirred and dispersed evenly;

[0057] b) The preparation of conductive carbon water-based slurry with a mass concentration of 4%: take 2kg of conductive carbon black SP-Li for lithium batteries, and take 0.1kg of polycarbonate according to the mass ratio of conductive carbon material and carboxyl compound as 1:0.05. Acrylic acid, add a certain amou...

Embodiment 2

[0063] Prepare the graphene material water-based slurry with a mass concentration of 0.1% and the conductive carbon water-based slurry with a mass concentration of 6% respectively:

[0064] a) preparation of graphene material water-based slurry with a mass concentration of 0.1%: take 40Kg of a graphene water-based slurry with a mass concentration of 5%, and take by weighing 1:0.01 according to the mass ratio of graphene material and polypyridine compound material 0.02Kg of dipyridin-4amine is added to the above-mentioned graphene aqueous slurry, diluted with water until the graphene content is 0.1%, and the above-mentioned mixture is stirred and dispersed evenly;

[0065] b) Preparation of conductive carbon water-based slurry with a mass concentration of 6%: Weigh 0.2kg of conductive carbon black SP-Li for lithium batteries, and weigh 0.2kg of conductive carbon black SP-Li according to the mass ratio of conductive carbon material and carboxyl compound as 1:1. 3,5-dinitrobenzoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com