A kind of graphene material powder and preparation method thereof

A technology of graphene and powder, which is applied in the field of graphene material powder and preparation, can solve the problems of difficult dispersion, easy agglomeration, unfavorable downstream product application, etc., and achieves simple and easy method, good compatibility and dispersibility, The effect of improving compatibility and decentralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a kind of preparation method of above-mentioned graphene material powder, and it comprises the following steps:

[0034] S110: Prepare graphene material aqueous slurry with a mass concentration of 0.1% to 3%, and add the liquid-absorbing and expanding material to the above-mentioned The graphene material aqueous slurry is prepared as an intermediate slurry.

[0035] In step S110, the source and preparation method of the graphene are not limited, and graphene products well known to those skilled in the art can be used or prepared by conventional preparation methods. Graphene of the present invention is preferably a graphene slurry or a graphene product provided by Ningbo Moxi Technology Co., Ltd. Graphene can be selected from graphene obtained by thermal expansion of graphene oxide prepared by any one of chemical oxidation methods such as Brodie method, Hummers method or Staudenmaier method. Graphene prepared by mechanic...

Embodiment 1

[0049] Get 100Kg mass concentration and be 3% graphene water-based slurry, take by weighing 0.03Kg fiber-polyacrylic acid graft polymer and join above-mentioned graphene material water-based slurry according to the mass ratio of graphene material and liquid-absorbing expansion material as 1:0.01 Prepare the intermediate slurry in the medium, and then treat it in an oven at 30-150°C until the solvent is completely evaporated.

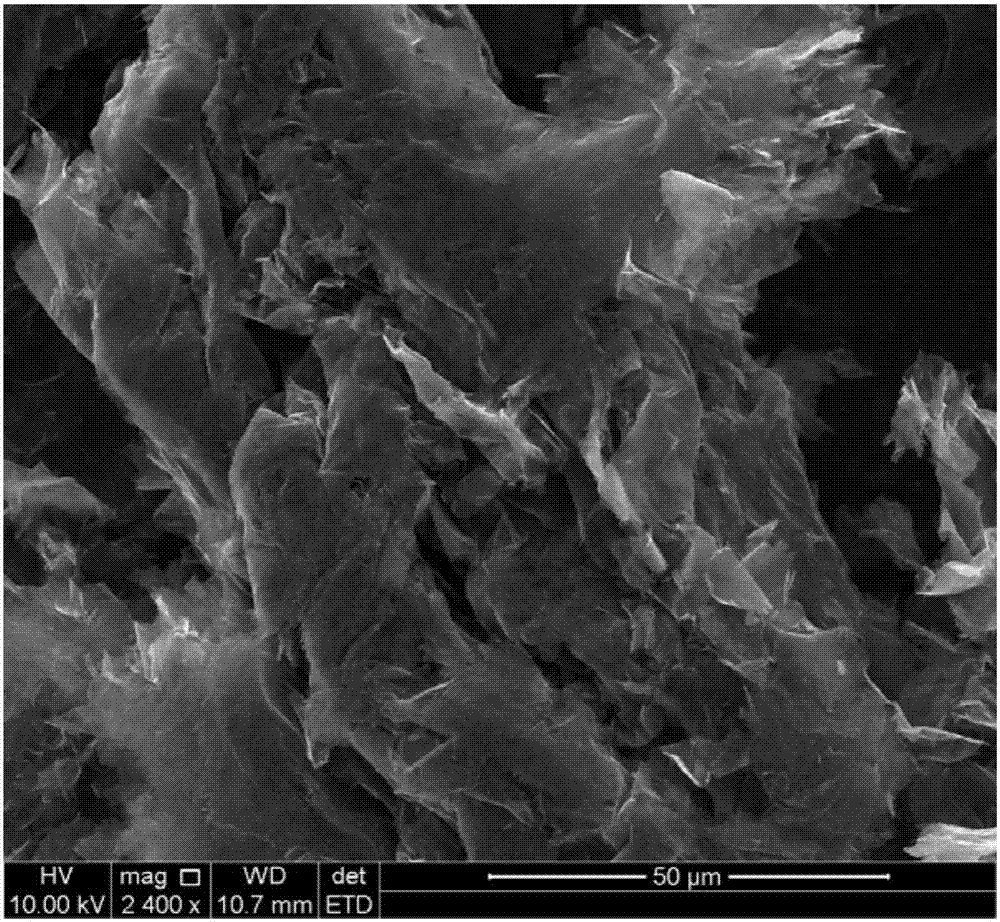

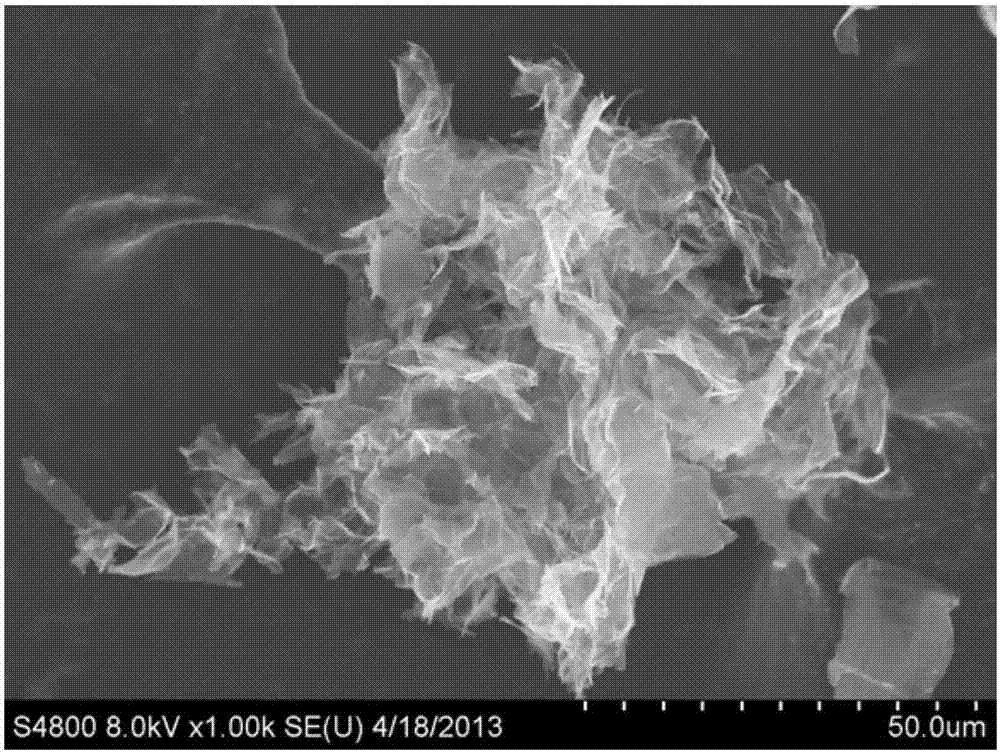

[0050] Depend on figure 1 It can be seen that the graphene material powder obtained in Example 1 of the present invention is basically agglomerated, such as figure 2 As shown, after ultrasonic dispersion in aqueous solution, the graphene sheets are well dispersed.

Embodiment 2

[0052] Get 100Kg mass concentration and be 0.1% graphene water-based slurry, according to the mass ratio of graphene material and liquid-absorbing expansion material is 1:10, take by weighing 1Kg starch-polyacrylic acid or its salt graft polymer and join above-mentioned graphene material The intermediate slurry is prepared from the water-based slurry; the intermediate slurry is spray-dried, the air inlet temperature is 200°C, and the outlet temperature is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com