Diamond wire backwinding machine

A technology of diamond wire and wire rewinding machine, which is applied in thin material processing, delivery of filamentous materials, transportation and packaging, etc. It can solve the problems that diamond wire does not meet the requirements of use, it is difficult to meet high-speed rewinding, time-consuming and labor-intensive, and achieves Excellent guiding effect, reducing wire jumping phenomenon, and improving wire reversing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

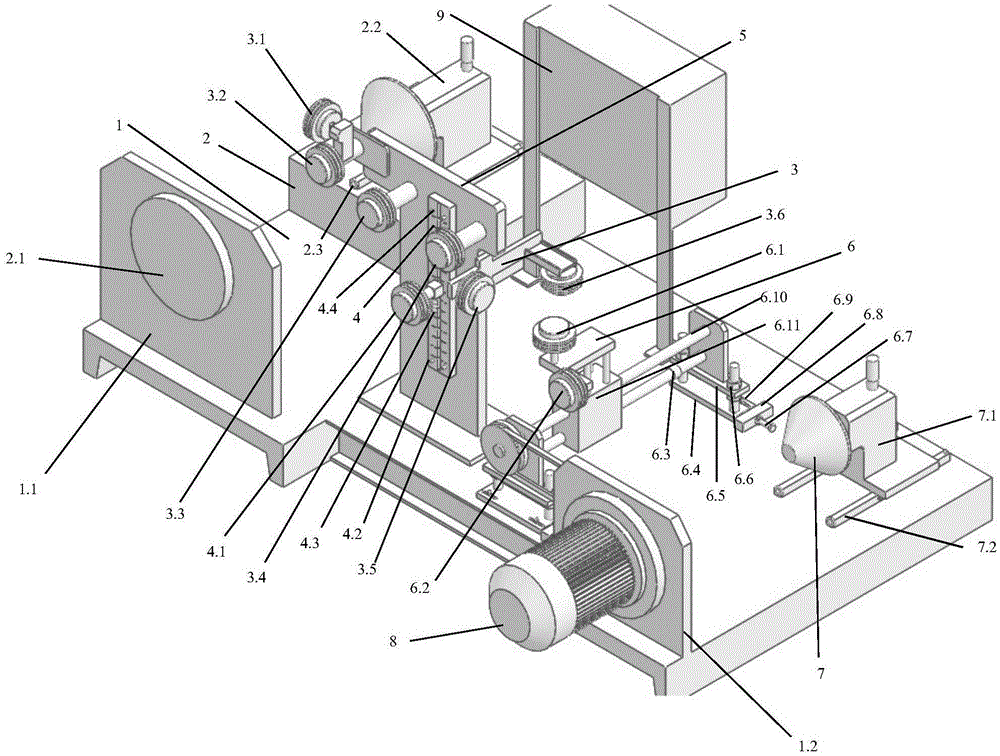

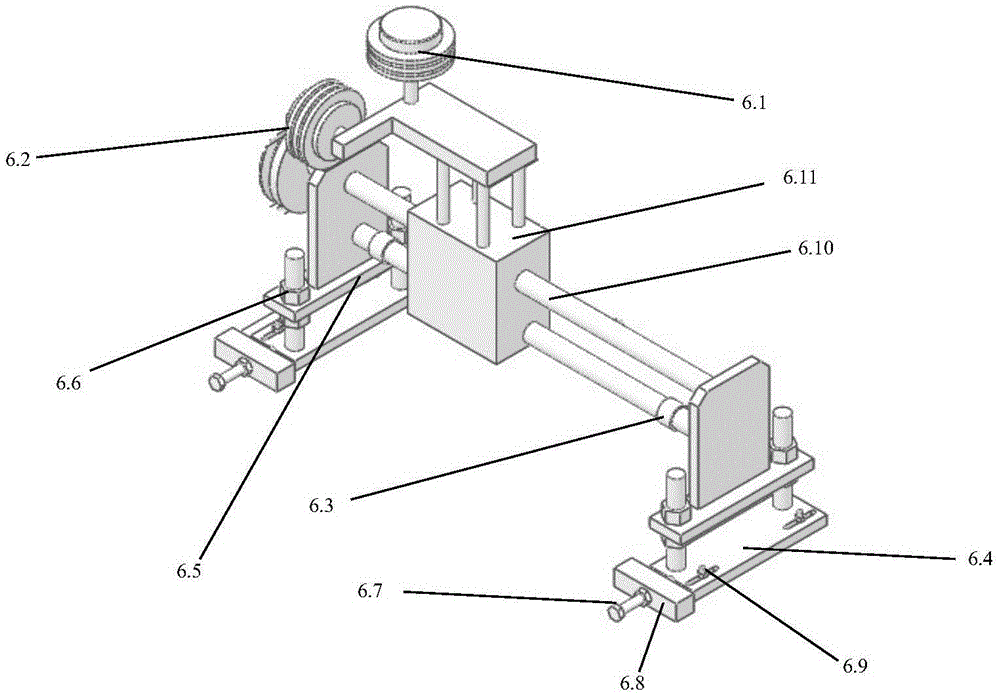

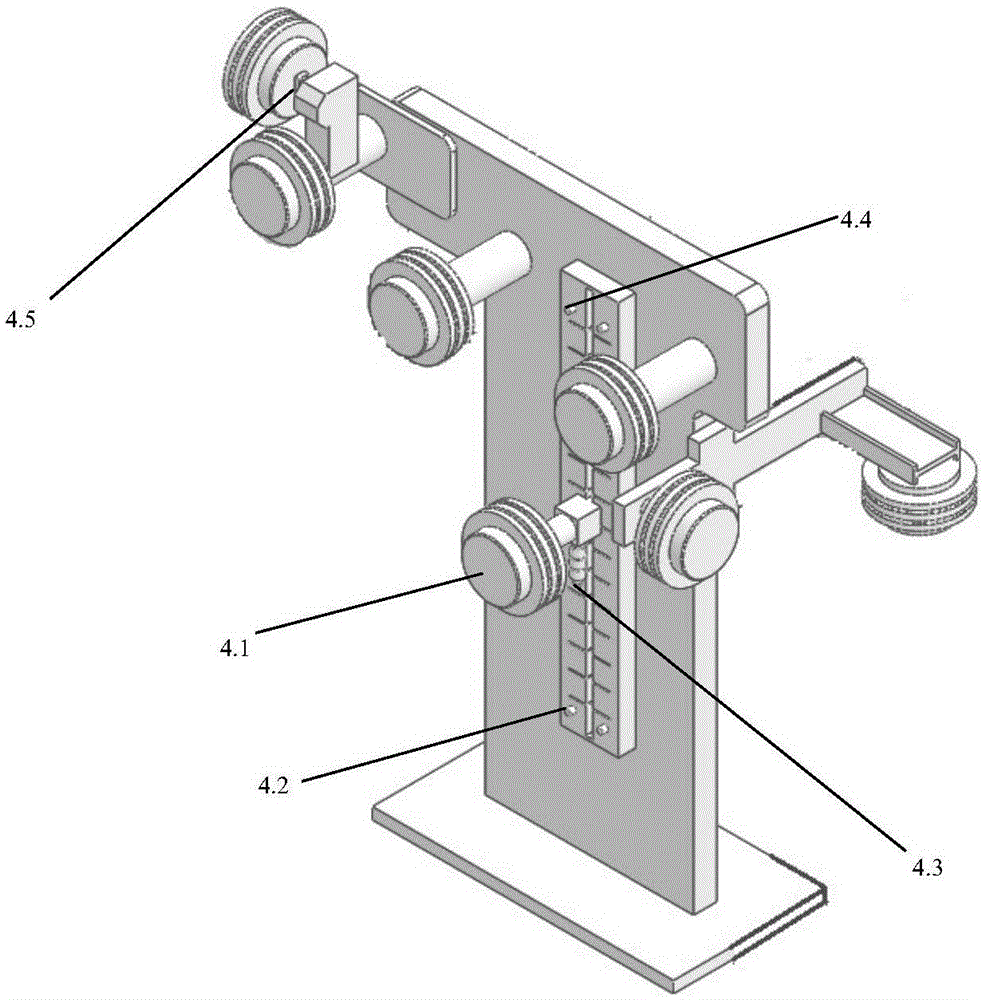

[0016] Such as figure 1 As shown, the present invention is a diamond wire rewinding machine capable of rewinding at high speed, including a frame 1, a pay-off machine 2, a guide wheel assembly 3, a tensioning mechanism 4, a wiring board 5, a wire arranging device 6, and a take-up Line machine 7, drive motor 8, electric control box 9. The pay-off machine 2 includes the pay-off wheel assembly 2.1, the pay-off wheel thimble 2.2 and the pay-off wheel thimble guide rail 2.3. The pay-off wheel assembly 2.1 is installed on the frame support plate 1.1, and the pay-off wheel thimble 2.2 is installed and fixed on the frame On the slide rail 2.3. Install one end of the diamond wire winding wheel of the large plate on the pay-off wheel assembly 2.1, and adjust the floating thimble 2.2 so that the small end of the thimble cone is inserted into the axis of the winding shaft to fix the spool axially. The structure and operation of the take-up machine are similar to those of the pay-off machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com