Integral sealing type electrical heat tracing anti-explosion material filling head

A technology of integral sealing and electric heat tracing, applied in the direction of liquid materials, packaging, packaging items, etc., can solve the problems of increased viscosity, long heating time of the charging gun, and fast heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

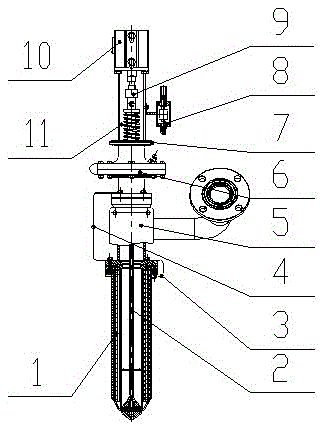

[0023] The present invention provides an integrally sealed electric heating explosion-proof charging head. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

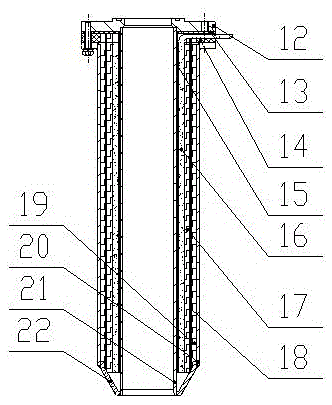

[0024] Integral sealed electric heating explosion-proof charging head includes sealing jacket type integral electric heating charging rod 1, valve core 2, grounding copper strip Ⅰ, grounding copper strip Ⅱ, tee body 5, sealing assembly 6, quick-change clamp 7. Sensor 8, connecting rod 9, cylinder 10, cylinder fixing seat 11, and a central control system composed of a data processing unit and an automatic control unit.

[0025] The sealing assembly 6 is tightly fixed on the upper end of the tee body 5 by bolt connection, the cylinder fixing seat 11 sits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com