Device and method for separating food residue and water

A food residue and separation device technology, applied in chemical instruments and methods, centrifuges, transportation and packaging, etc., can solve the problems of non-reuse, high energy consumption, and non-recyclable garbage, so as to facilitate recycling and improve Separation effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

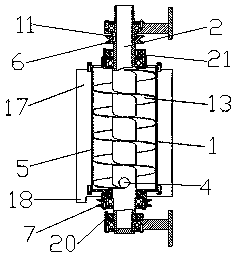

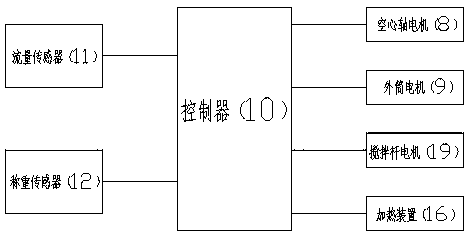

[0027] A food residue and water separation device, such as figure 1 As shown, including a bracket, the device includes an outer cylinder 1 and a hollow shaft 2 whose axial direction is perpendicular to the horizontal plane, and the hollow shaft is arranged in the outer cylinder, and its upper and lower ends extend out of the outer cylinder and are connected with the bracket bearings , the hollow shaft and the outer cylinder are respectively bearing-connected at the intersections of the upper and lower end faces, the hollow shaft one-way device 20 is provided on the bearing connected to the hollow shaft and the bracket, and the outer cylinder is provided on the bearing connected to the hollow shaft and the outer cylinder One-way device 21, the direction of the hollow shaft one-way device is opposite to that of the outer cylinder one-way device; as figure 2 As shown: near the lower end of the hollow shaft, there is fixed a blocking plate 3 with an interference fit with it perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com