Automatic detecting device and method for large-array resistance strain gauge

An automatic detection device, resistive strain technology, applied in electromagnetic measurement device, measurement device, electric/magnetic solid deformation measurement, etc. High efficiency, high work efficiency, and the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

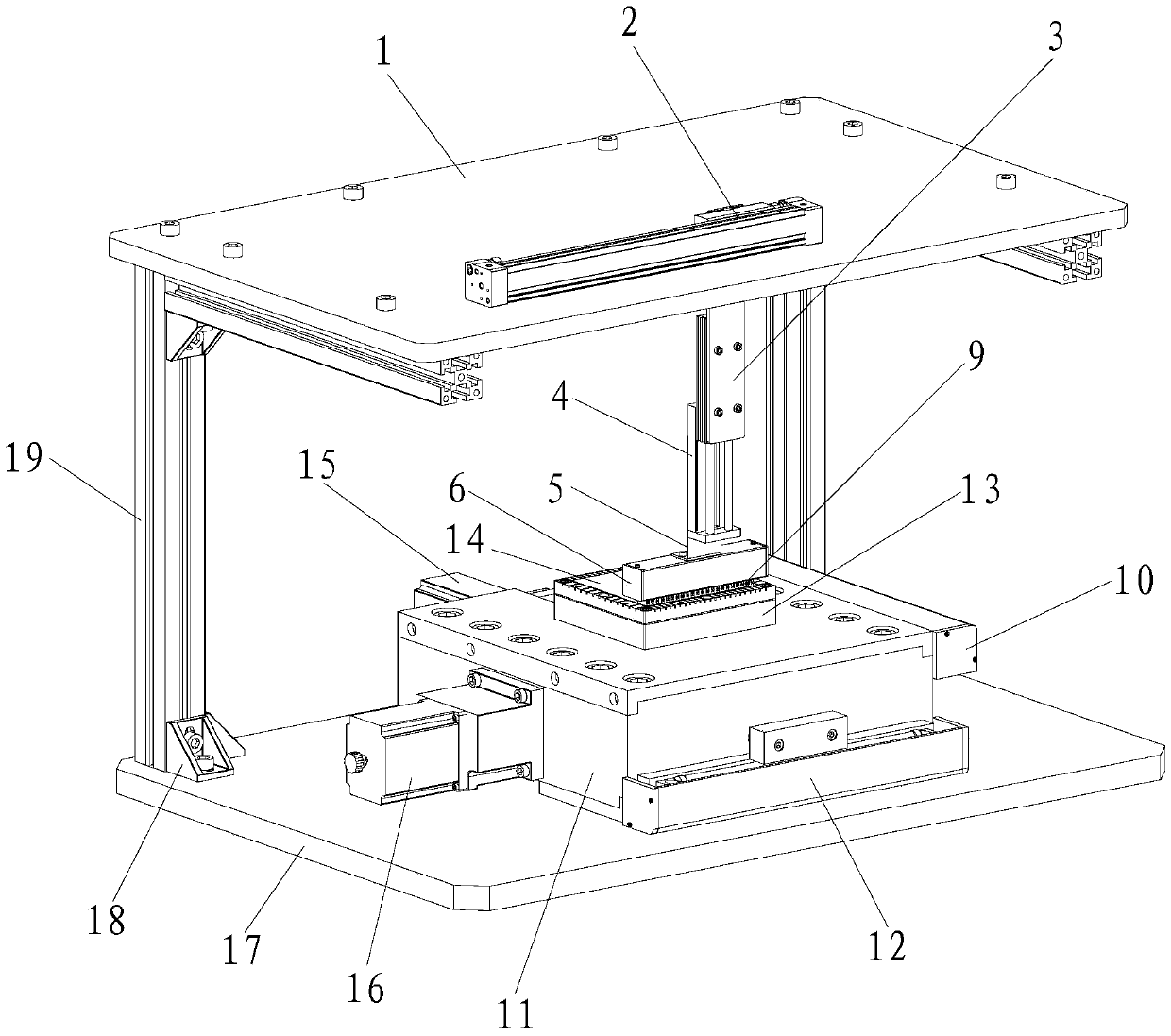

[0064] Such as figure 1 and Figure 4 As shown, the large array resistive strain gauge automatic detection device of the present invention includes a frame, a positioning and fixing mechanism, a detection mechanism and a computer 35, and the computer 35 is connected with a data acquisition board 36 and a desktop digital multimeter 37. The signal output terminal of the data acquisition board 36 is connected with an output amplifier board 38;

[0065] The frame includes an upper top plate 1 and a lower bottom plate 17 spaced up and down, and a pillar supported between the upper top plate 1 and the lower bottom plate 17;

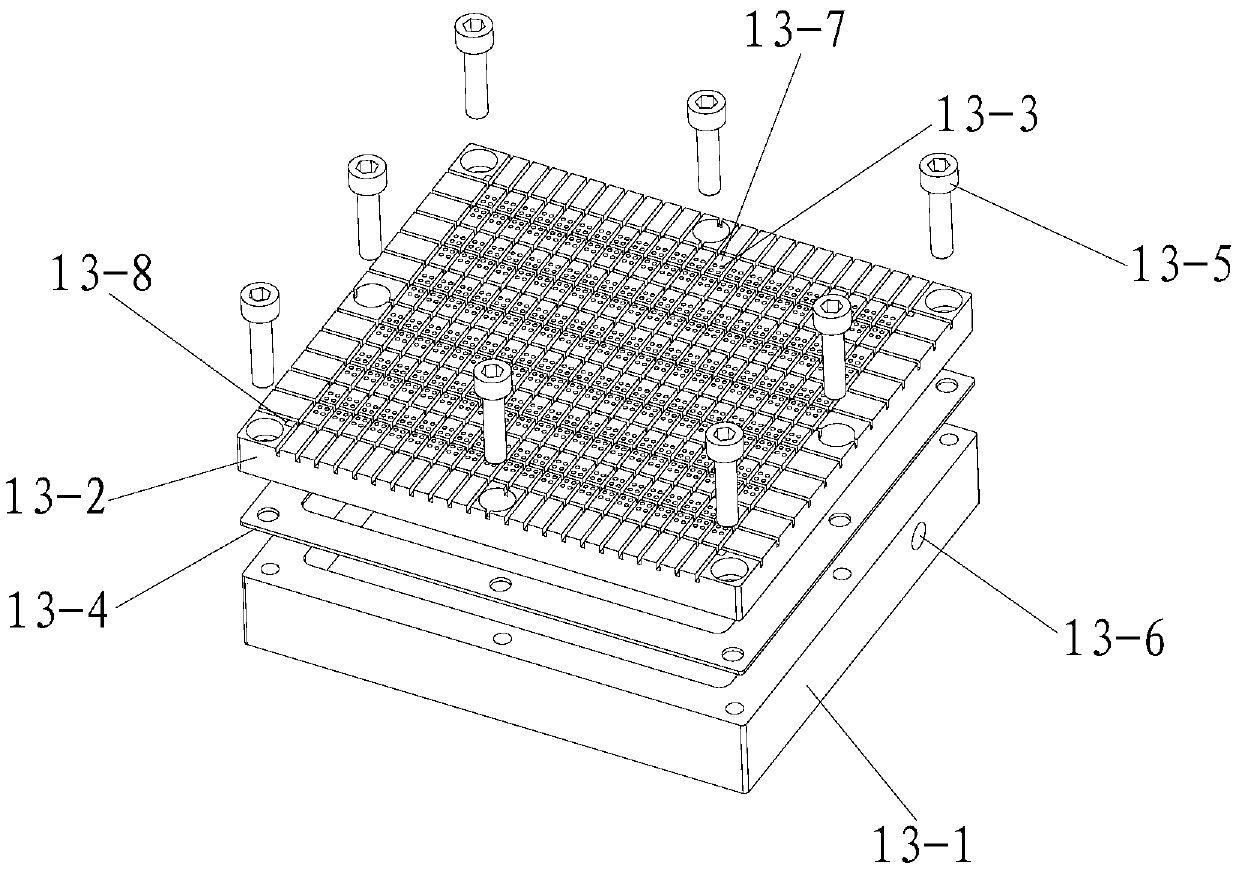

[0066] The positioning and fixing mechanism includes a two-dimensional mobile platform 11 installed on the top of the lower base plate 17, a vacuum adsorption table 13 installed on the top of the two-dimensional mobile platform 11, and a vacuum adsorption circuit for vacuuming the vacuum adsorption table 13. Mobile platform 11 comprises X-axis moving motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com