Stepped impact resistant damper

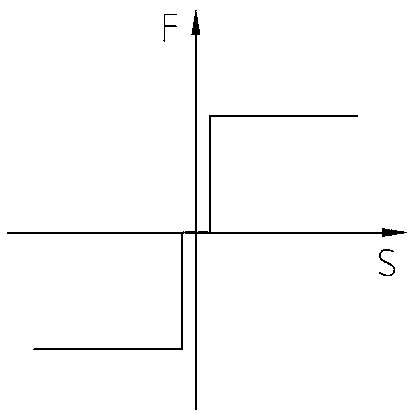

A damper, stepped technology, applied in shock absorbers, shock absorbers, gas-liquid shock absorbers, etc., can solve the problems of tearing and failure of vibration isolators, increased equipment acceleration, and limited energy absorption effect. Avoid excessive impact acceleration of equipment, reduce impact response, and high energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

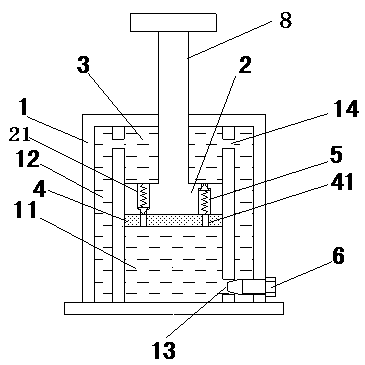

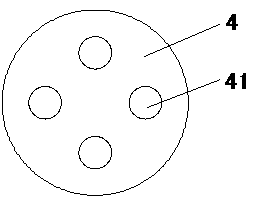

[0014] see figure 1 and figure 2 . A stepped anti-shock damper according to an embodiment of the present invention includes a housing 1 , a piston 2 , and a piston rod 8 connected to the piston 2 , and the housing is filled with damping fluid 3 . The piston 2 is provided with at least one pair of throttling holes 21 penetrating along the thickness direction of the piston 2 , and each throttling hole is provided with a check valve 5 . In each pair of orifices, the flow direction of the damping fluid allowed by the check valve in one of the orifices is opposite to that of the check valve in the other orifice, that is, the check valve in one of the orifices only The damping fluid in the cavity above the piston is allowed to flow into the cavity below the piston through the orifice, while the check valve in the other orifice only allows the damping fluid in the cavity below the piston to flow into the cavity above the piston through the orifice. In the embodiment shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com